Adhesion promoter for bonding elastomers and metals and adhesive composition

An adhesion promoter and composition technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, polymer adhesive additives, etc. and other problems, to achieve the effect of excellent aging resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

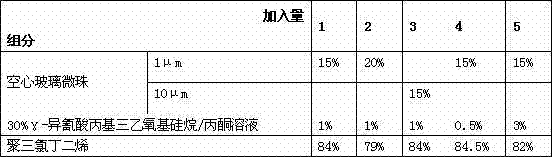

[0057] Example 1 Adhesion promoter

[0058]

[0059] Follow the steps below to synthesize the adhesion promoter:

[0060] a. Soak the porous inorganic filler in 30% silane coupling agent / acetone solution at 60°C for 4 hours, then filter and dry;

[0061] b. The modified filler obtained in the previous step and the polyolefin are internally mixed with an internal mixer at a temperature of 80°C for one hour.

[0062] c. After the colloid obtained from banburying is discharged, it is prepared into an aqueous dispersion according to a well-known method in the industry to obtain an adhesion promoter.

[0063] The formula number corresponding to the finished adhesion promoter is as follows:

[0064] serial number 1 2 3 4 5 Adhesion Promoter Ad.1 Ad.2 Ad.3 Ad.4 Ad.5

Embodiment 2

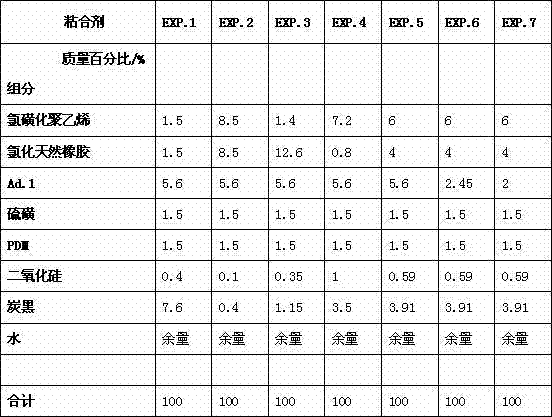

[0065] Example 2 Adhesive composition EXP.1-EXP.7

[0066]

Embodiment 3

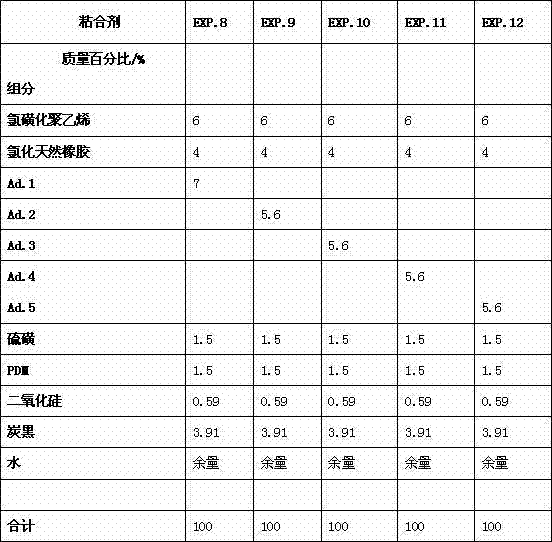

[0067] Embodiment 3 adhesive composition EXP.8~EXP.12

[0068]

[0069] Product application examples:

[0070] After the preparation of the above-mentioned EXP.1-EXP.12 series of adhesive compositions is completed, the metal substrates to be bonded shall be sandblasted and cleaned. When used as a single coating, dip coating (or roller coating / brush coating) Coating / spraying) This adhesive is baked at 80°C for 10 minutes, and the dry film thickness is controlled at 20-30 μm; when used as a double coating, dip coating (or roller coating / brush coating / spray coating) on the surface of the metal substrate ( For example, CH 8007 of Lord Corporation of the United States, Polyton 910 of Shanghai Polyton Corporation, etc.), bake at 80°C for 10 minutes, control the dry film thickness at 5-10 μm, and then dip (or roll / brush / spray) on the primer The adhesive is baked at 80°C for 10 minutes, and the dry film thickness is controlled at 10-20 μm; then the elastomer and the sized me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com