Differential temperature and pressure tester for horizontal well for thermal recovery

A technology for horizontal wells and testers, which is used in wellbore/well components, measurement, earth-moving drilling and production, etc. It can solve the problem of not ensuring uniform steam absorption, liquid production, inefficiency, and inability to fully utilize horizontal well sections in long horizontal sections. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

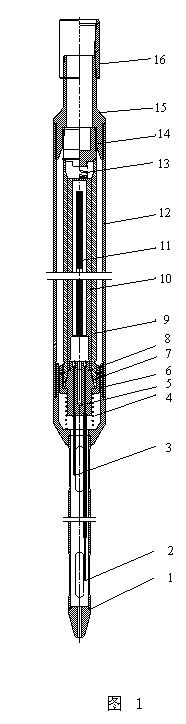

[0016] Such as figure 1 as shown, figure 1 It is a structural diagram of the thermal recovery horizontal well differential well temperature and well pressure tester of the present invention. The thermal recovery horizontal well differential well temperature and well pressure tester consists of a guide head 1, a first temperature sensor 2, a second temperature sensor 3, an anti-collision spring 4, a pressure sensor probe 5, a tightening nut 6, a sealing copper Pad 7, sensor body seat 8, instrument inner protection cylinder 9, thermos bottle 10, data acquisition circuit 11, instrument outer protection cylinder 12, damping spring 13, plug 14, reducing joint 15 and tubing collar 16.

[0017] The guide head 1 can ensure that the instrument is smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com