Self-control adjusting steam trap

A steam trap and steam technology, applied in steam traps, mechanical equipment, etc., can solve problems such as energy waste and steam leakage, and achieve the effects of wide application range, prevention of steam leakage, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

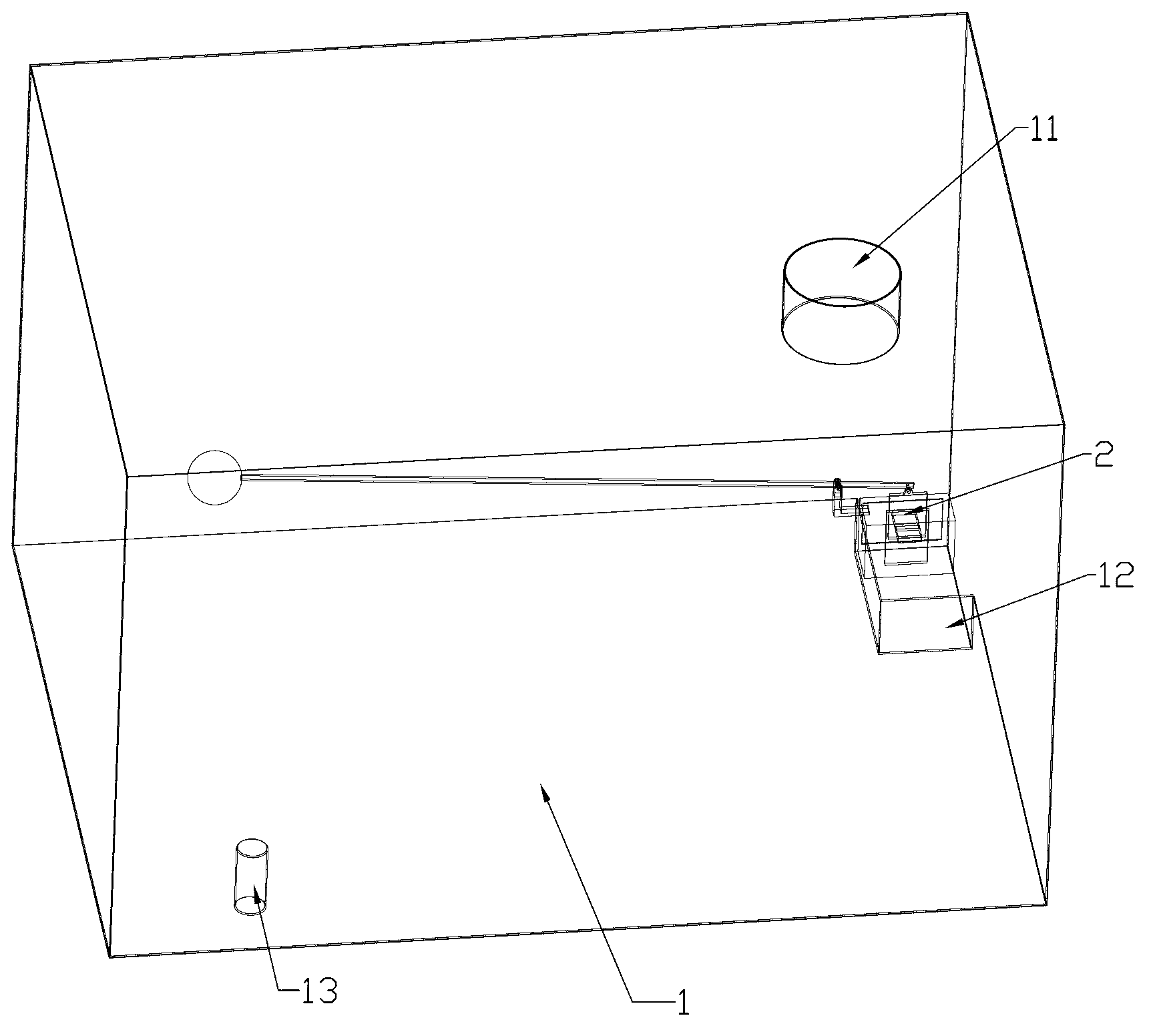

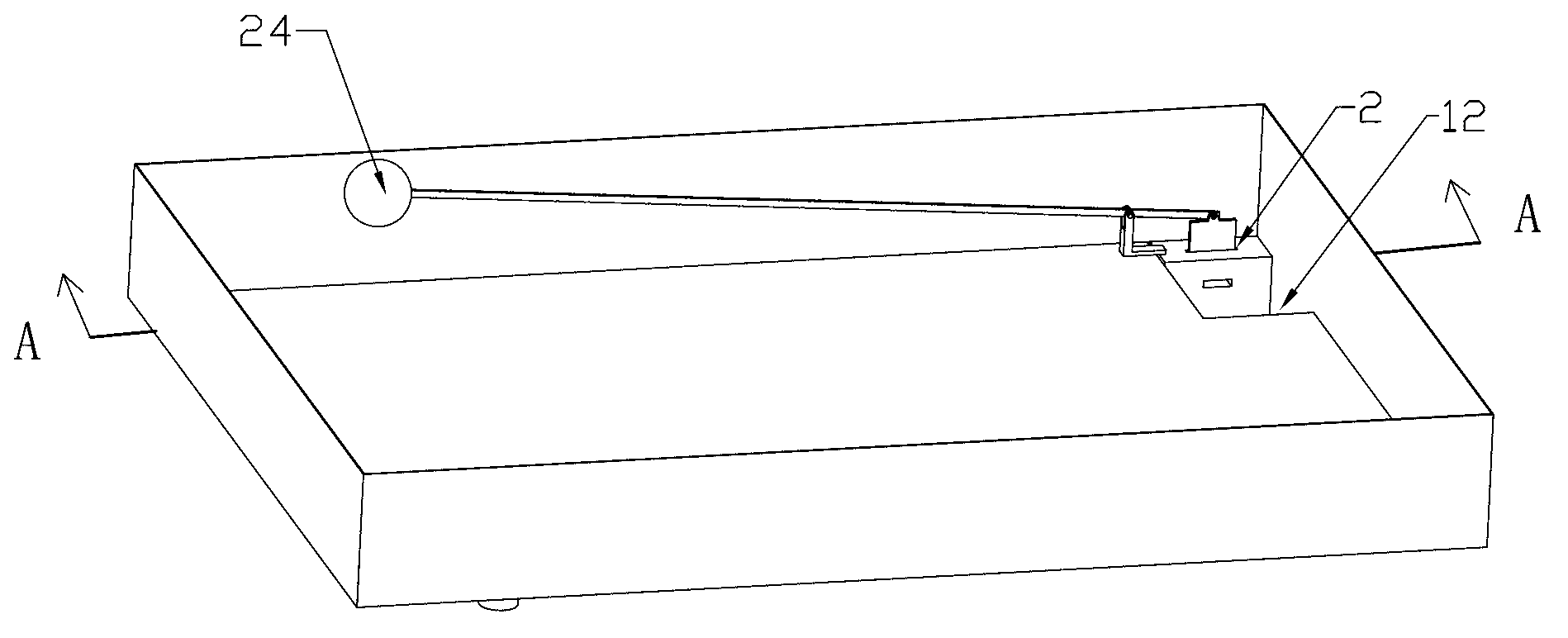

[0013] Such as Figure 1 ~ Figure 4 ,

[0014] A steam trap with self-control regulation includes a box body 1 and a float drainage mechanism 2 . The volume of the box body 1 is large enough, and the pipe interface 11 connected with the drain port of the steam pipe is provided on the upper part of the box body 1, and the condensed water in the steam pipe is collected into the box body by dripping, There is a drainage tank 12 equipped with a float drainage mechanism. The horizontal position of the drainage groove 12 is the lowest, and the condensed water is discharged to the outside through the opening of the drainage mechanism. depth. For the convenience of overhaul and maintenance, a vent valve 13 is provided at the bottom of the box to vent the water inside.

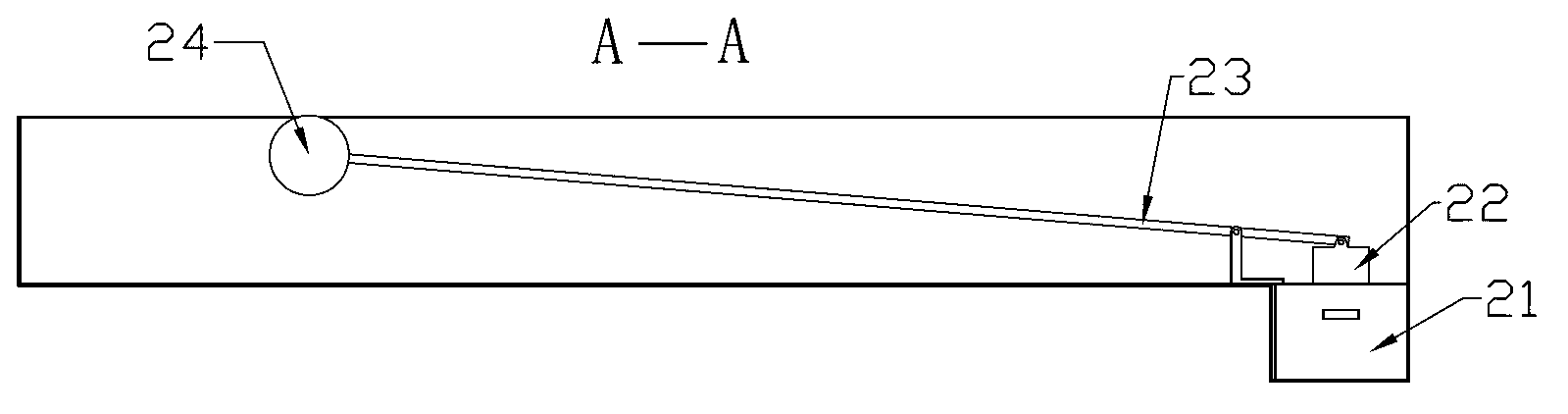

[0015] Specifically, the float drainage mechanism 2 is composed of a valve block 21, a valve body 22, a lever 23 and a floating ball 24. The valve block 21 is a square body, and there are vertical valve body grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com