Lithium battery and tab cutting device

A lithium battery, cutting technology, applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of affecting battery safety performance, easy to puncture, etc., achieve smooth transition, avoid the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

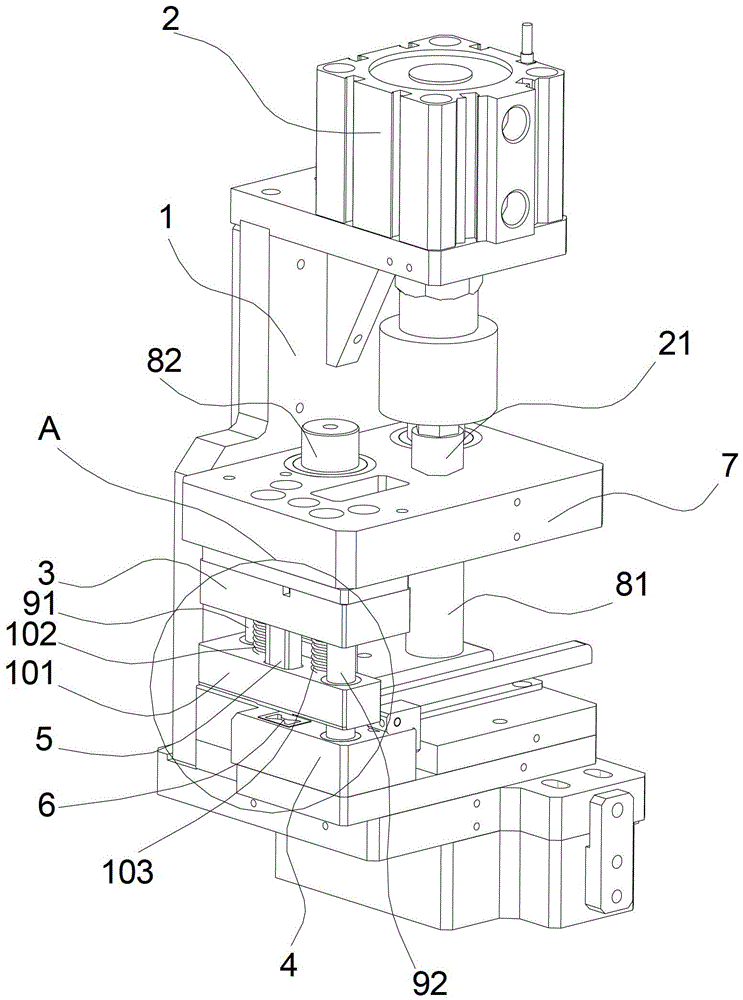

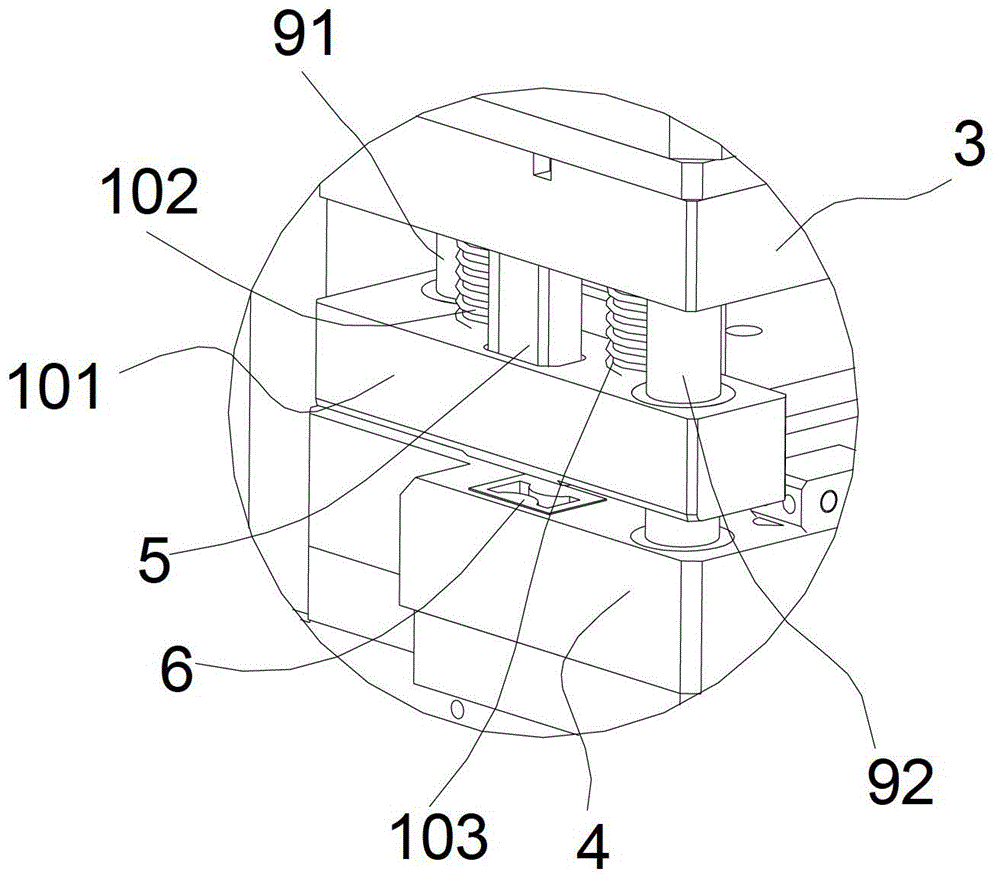

[0033] Please refer to Figure 2-4 , In the first embodiment, the lithium battery tab cutting device includes a machine base 1, a cylinder 2, an upper mold base 3, a lower mold base 4, an upper knife mold 5, a lower knife mold 6, and a mold base connecting plate 7.

[0034] The air cylinder 2 is installed on the machine base 1, and the air cylinder 2 drives the upper mold base 3 and the upper knife mold 5 to move back and forth on a cutting path as a power mechanism. The power output end 21 of the cylinder 2 is fixedly connected with the upper mold base 3, and the fixed connection includes a direct fixed connection and an indirect fixed connection. In the first embodiment, the upper mold base 3 is fixedly connected to the power output end 21 of the cylinder 2 through the mold base connecting plate 7. Specifically, please refer to figure 2 , the upper part of the die base connecting plate 7 is fixedly connected with the power output end 21 of the cylinder 2, and the lower par...

Embodiment 2

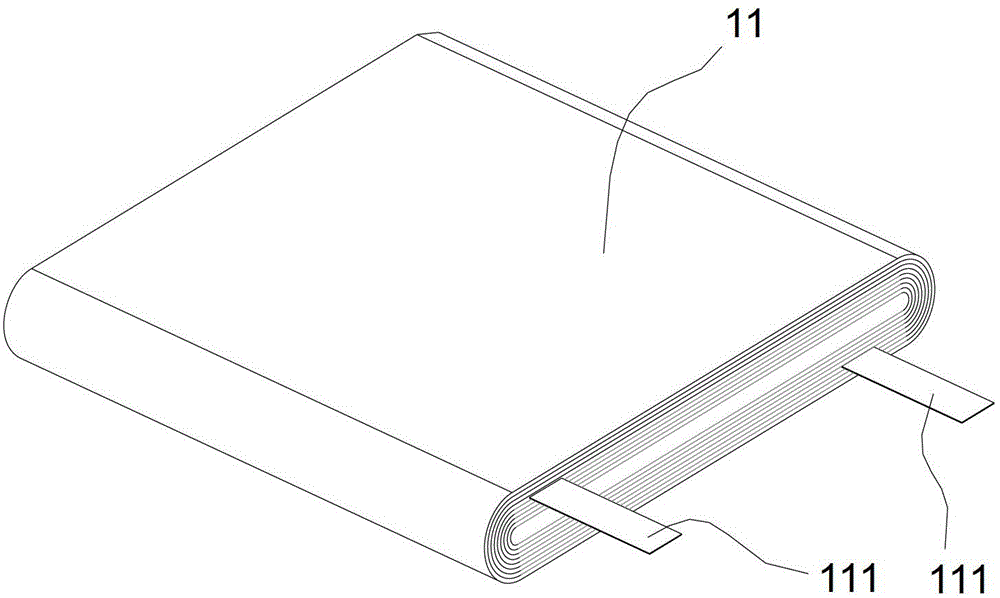

[0044] The second embodiment provides a lithium battery, which includes a positive electrode sheet, a negative electrode sheet, a diaphragm and other components, and tabs are provided on both the positive electrode sheet and the negative electrode sheet. In the second embodiment, the tab is cut by the cutting device described in any of the embodiments of the present application. After cutting, the tab has an arc-shaped outer edge, which is convenient for the subsequent processing and transportation of the battery cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com