Blade sharpening system for agricultural implements

一种刃磨、农具的技术,应用在农业机械和机具、应用、磨床等方向,能够解决不能有效地锐化带槽的或波状的刀片等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

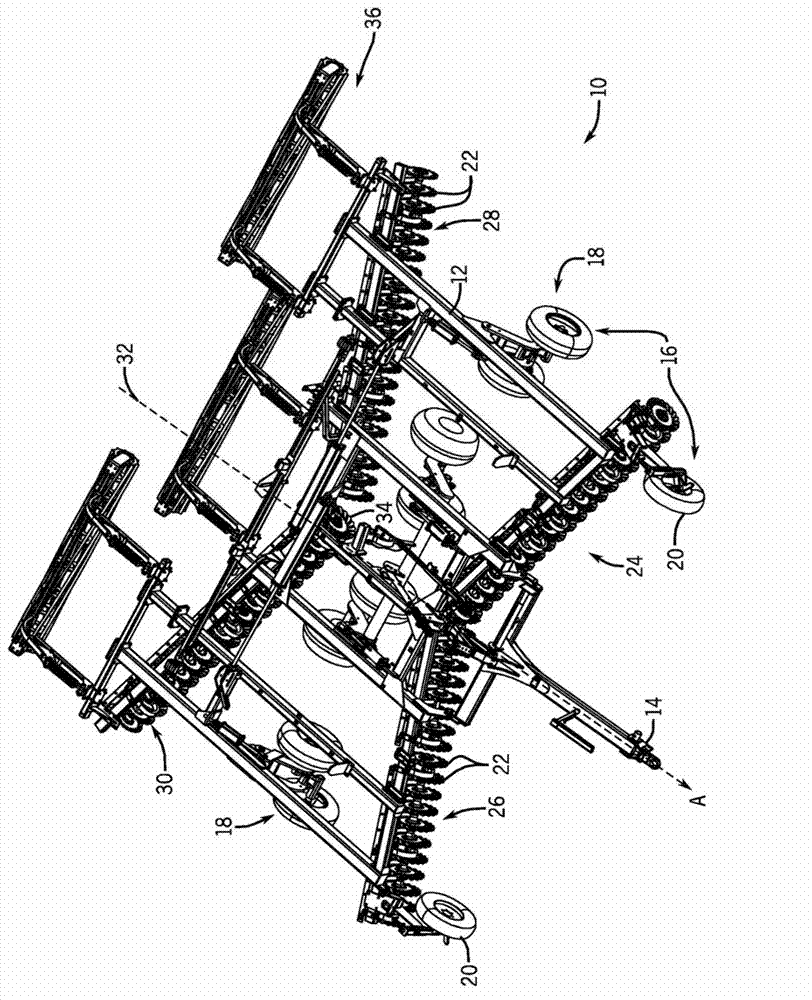

[0014] Referring now to the accompanying drawings, figure 1 is a perspective view of an exemplary agricultural implement 10 . While a vertical tillage implement 10 is shown and described below, it should be understood that the sharpening system may be used to sharpen blades on any other suitable agricultural implement. It will be appreciated that the agricultural vehicle is configured to tow the vertical tillage implement 10 along the direction of motion A. The vertical tiller 10 includes a main frame 12 . On the front end of the main frame 12 is a hitch 14 which may be used to connect the vertical tillage implement 10 to an agricultural vehicle such as a tractor or other tractor. In addition, the main frame 12 is connected with a set of wheels 16 . Said set of wheels 16 is oriented in a direction generally aligned with the direction A of motion. The set of wheels 16 includes a set of center wheels 18 and a set of pivot wheels 20 . The set of center wheels 18 is attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com