Method for recontouring a compressor or turbine blade or vane for a gas turbine

A technology for turbine blades and gas turbines, applied in turbines, blade support elements, machines/engines, etc., can solve problems such as troublesome on-site execution, inability, and troublesome repair methods, and achieve the effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

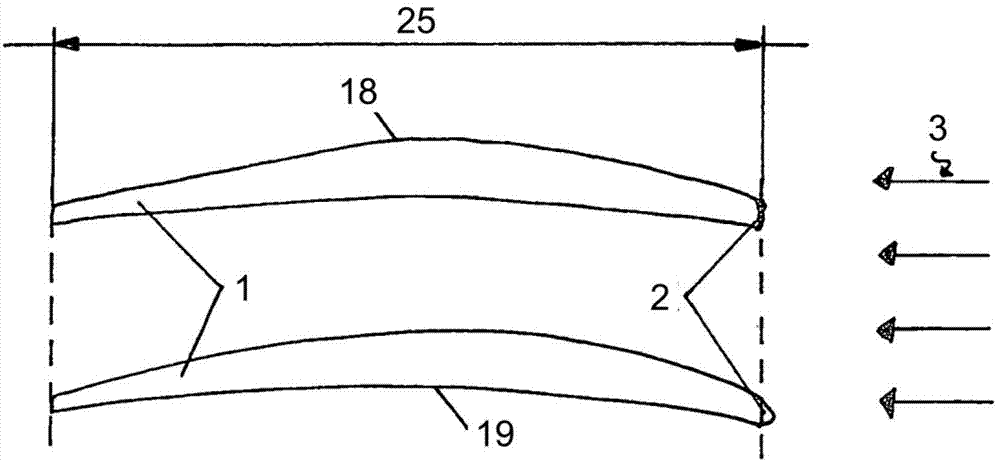

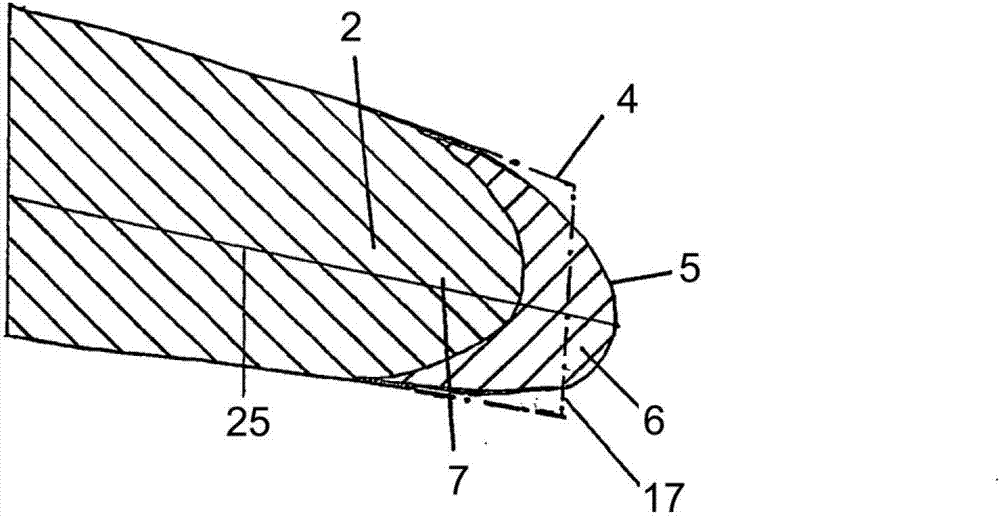

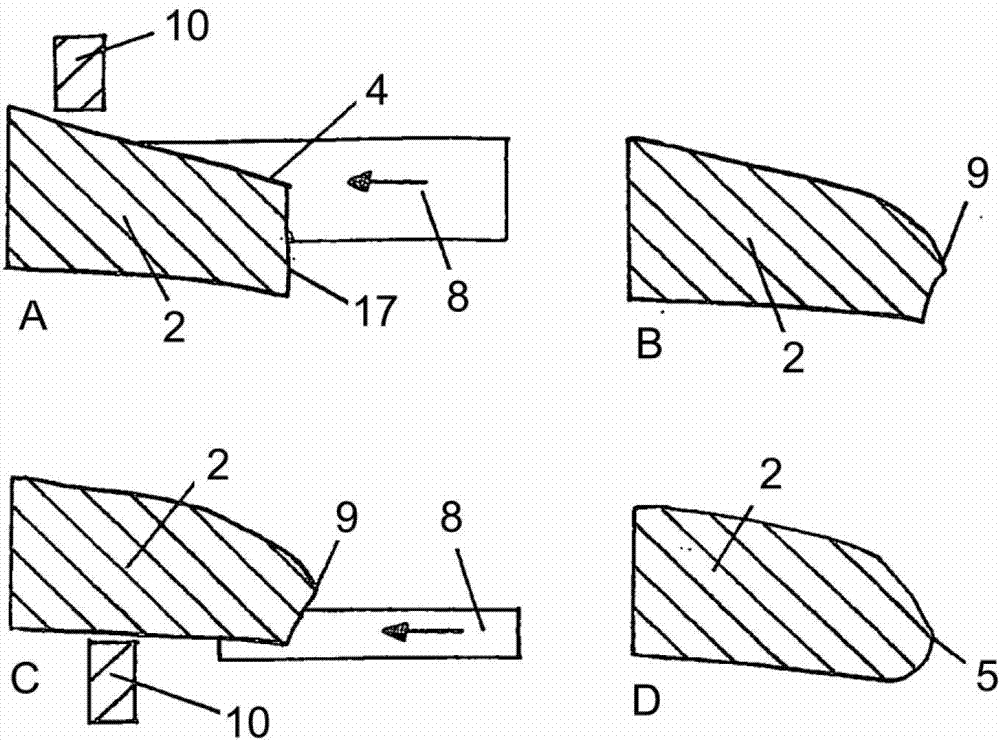

[0028] figure 1 Two compressor blades 1 , so-called fan blades, of a first compressor stage of an aircraft power plant are schematically shown in . Two compressor blades 1 are arranged one above the other, wherein the air flow 3 flows in from the right during operation. The compressor blades 1 each have an upper suction side 18 and a lower pressure side 19 as well as an inlet edge 2 , also referred to as a leading edge, facing the air flow 3 . The length from the inlet edge 2 of the compressor blade 1 to the outlet edge of the compressor blade 1 is the chord length 25 or also referred to as “chord width” of the compressor blade. The upper compressor blade 1 is damaged and shortened by erosion in the region of the entry edge 2 , the lower compressor blade 1 has been repaired by the repair method according to the invention and no longer has this damage. exist figure 2 The entry edge 2 is shown enlarged. In this case, the state of the entry edge before the repair according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com