Double comb cage with mass balance for double row cylindrical roller bearings

A cylindrical roller bearing, double-comb technology, applied in the direction of roller bearings, bearing components, shafts and bearings, to achieve the effect of mass distribution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

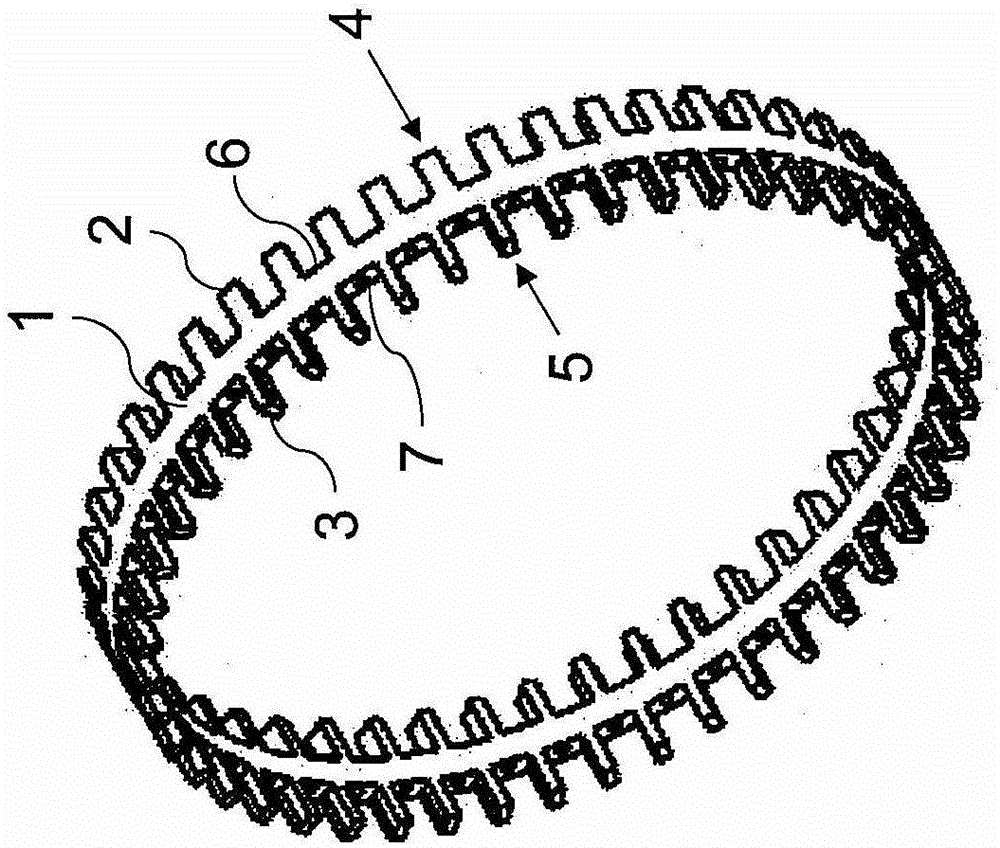

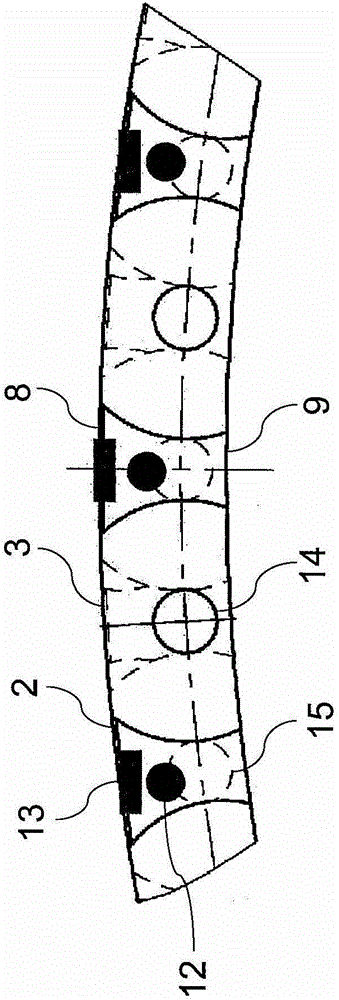

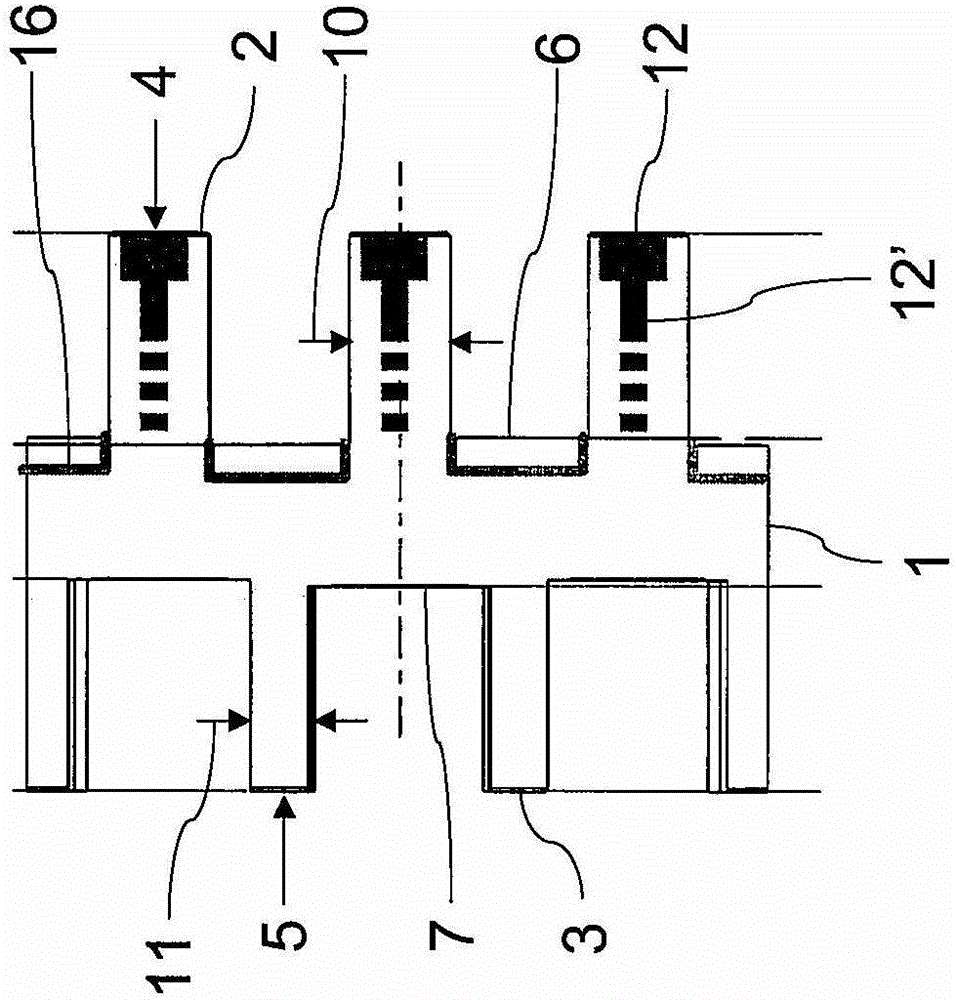

[0026] figure 1The double-comb cage for double-row cylindrical roller bearings, for example made of brass in one piece and combined into a ring, shown in , comprises a central ring 1 extending axially from both sides of the ring The webs 2, 3 are offset from each other. The webs 2 , 3 on both axial sides of the cage are arranged evenly distributed over the circumference and accordingly form bearing rows 4 , 5 for rolling elements or cylindrical rollers (not shown). Each two adjacent webs 2 or 3 form a receiving pocket 6 or 7 for a cylindrical roller. In order to clamp and support the cylindrical rollers in the receiving pockets 6, 7, such as figure 2 As shown in , the webs 2 , 3 can be contoured in a manner known per se between the radially outer bottom side 8 and the radially inner bottom side 9 . The not shown outer and inner rings of the cylindrical roller bearing are likewise designed in a manner known per se and will not be described in detail here.

[0027] The webs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com