Circular comb for circular comber

A technology of combing machine and circular comb, applied in the field of circular combing of combing machine, can solve the problems of undesired vibration of the device, shorten the service life, etc., and achieve the effect of increasing the value of the comb jaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

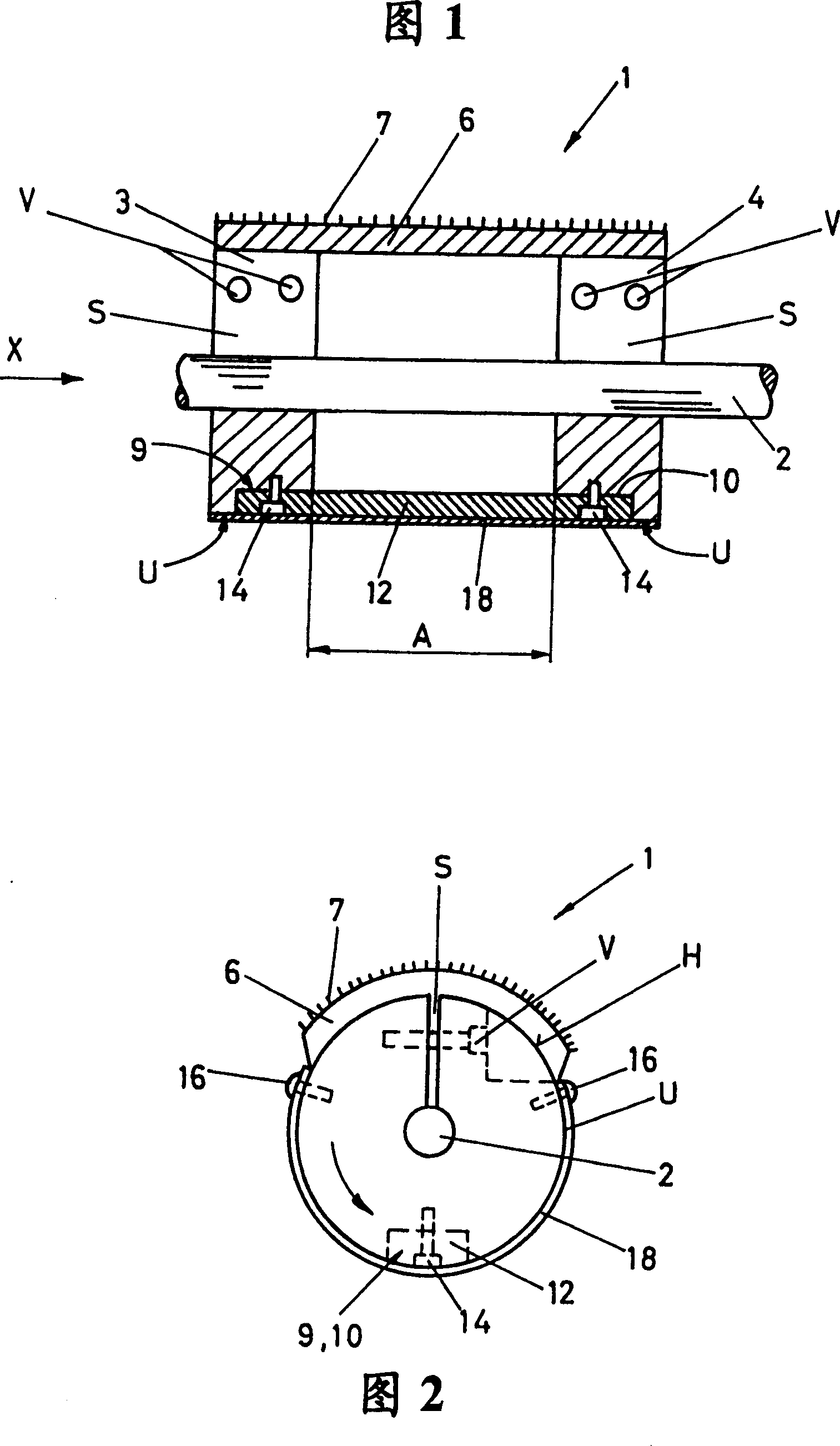

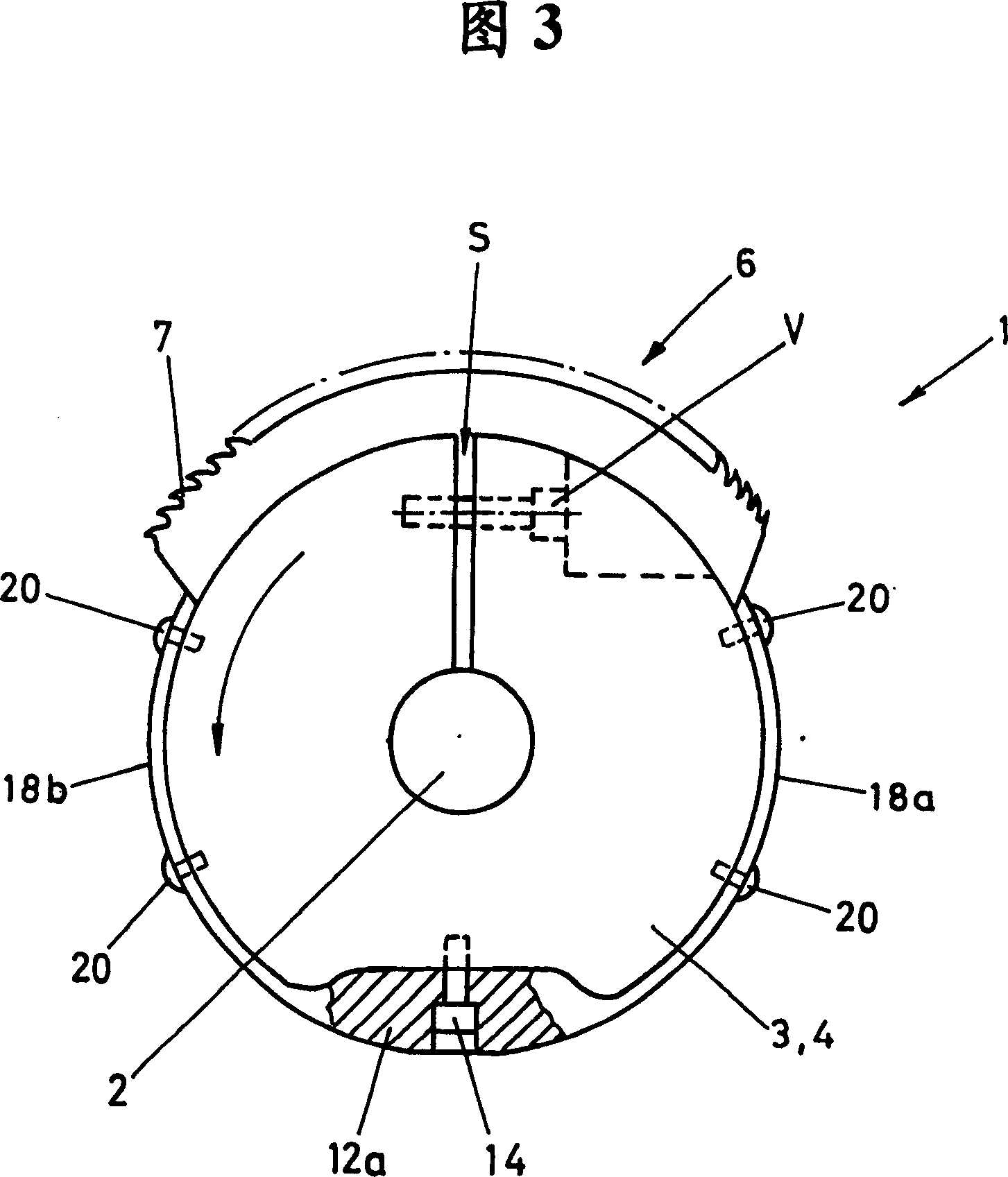

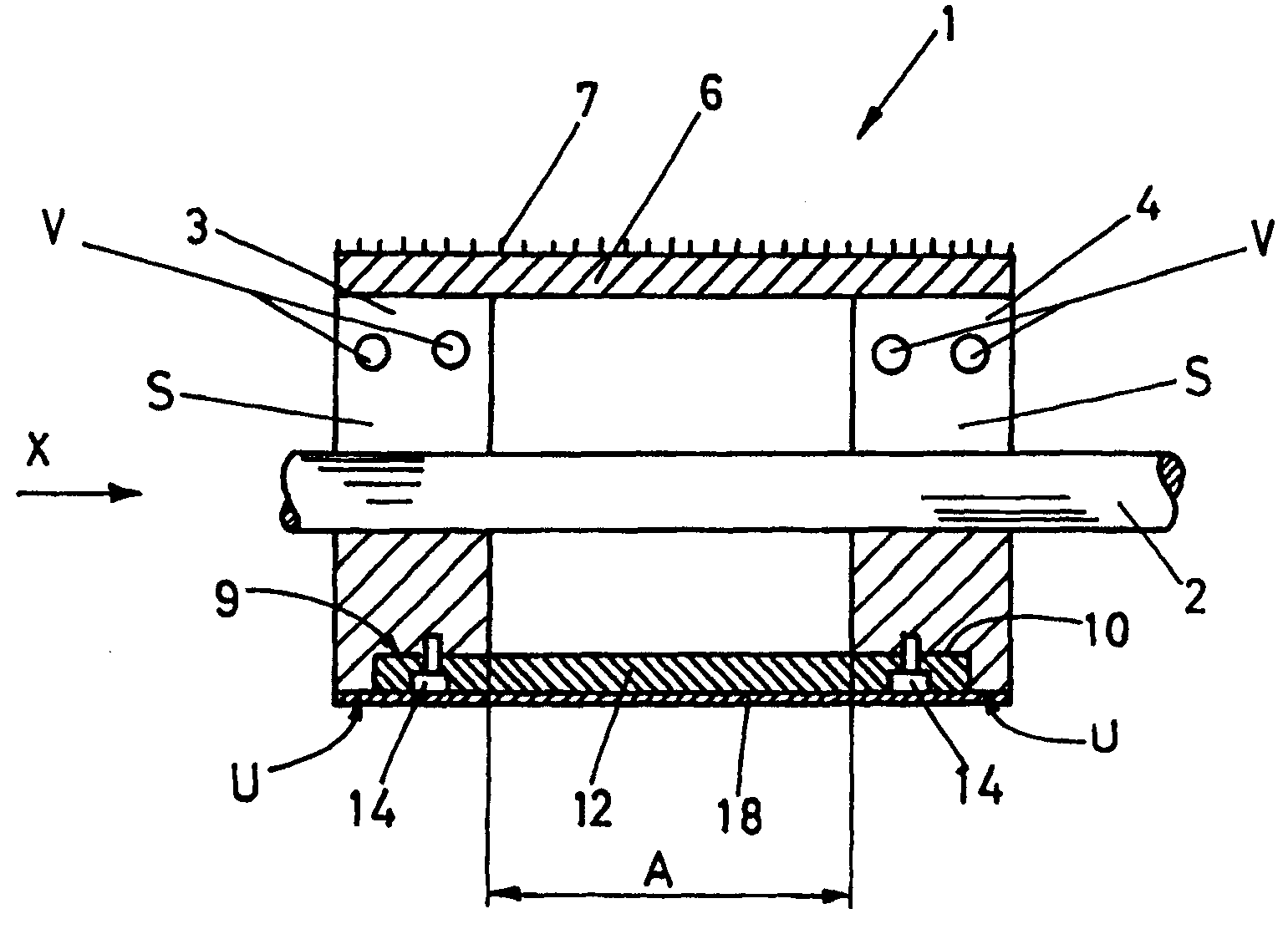

[0027] The circular comb 1 shown in FIG. 1 has a circular comb shaft 2 to which the disk parts 3 , 4 are fastened in a rotationally fixed manner. The disc members 3, 4 are in each case provided with a slot S, which can be firmly clamped on the shaft 2 by means of a threaded connection V, as shown schematically in the figure. The circular comb part 6 is fixed to the disc members 3, 4 by a not shown screw connection, the circular comb is provided with a comb structure 7, shown schematically in the figure, for combing a mass of fibers by means of not shown jaws.

[0028] The counterweight 12 is fixed to the cutouts 9 , 10 on the disc members 3 , 4 of the opposing circular comb portion 6 by means of schematically shown screws 14 . A cover 18 in the form of a sheet metal casting is fastened by screws 16 to the circumference of the disc members 3, 4 so as to cover the free space between the disc members 3, 4. The purpose of this is to suppress the uncontrolled flow of air, which co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com