Novel roll gap adjusting device of short-stress-path rolling mill

A technology of short stress line and adjustment device, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem that the installation accuracy of the left and right bevel gear shafts is not easy to ensure, increase the number of tie rods and adjust the nut spare parts , affecting the smooth operation of the equipment, etc., to improve the self-positioning performance, reduce the harmful contact area, and easily ensure the installation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

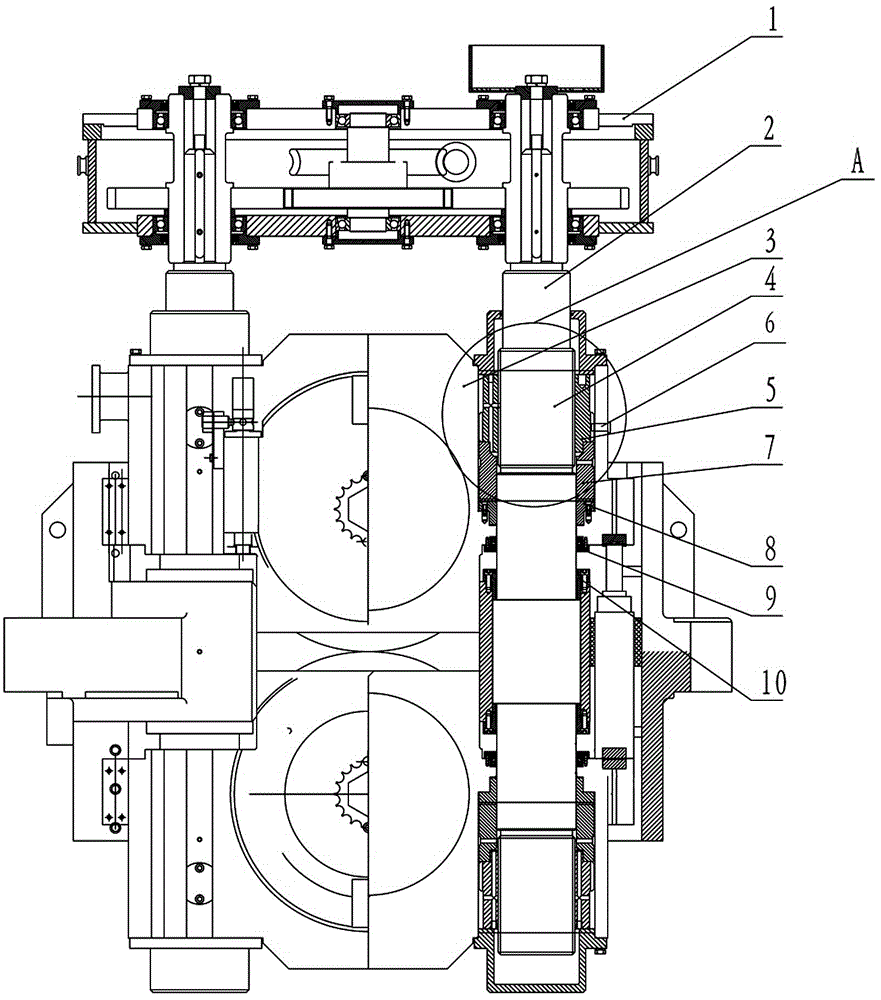

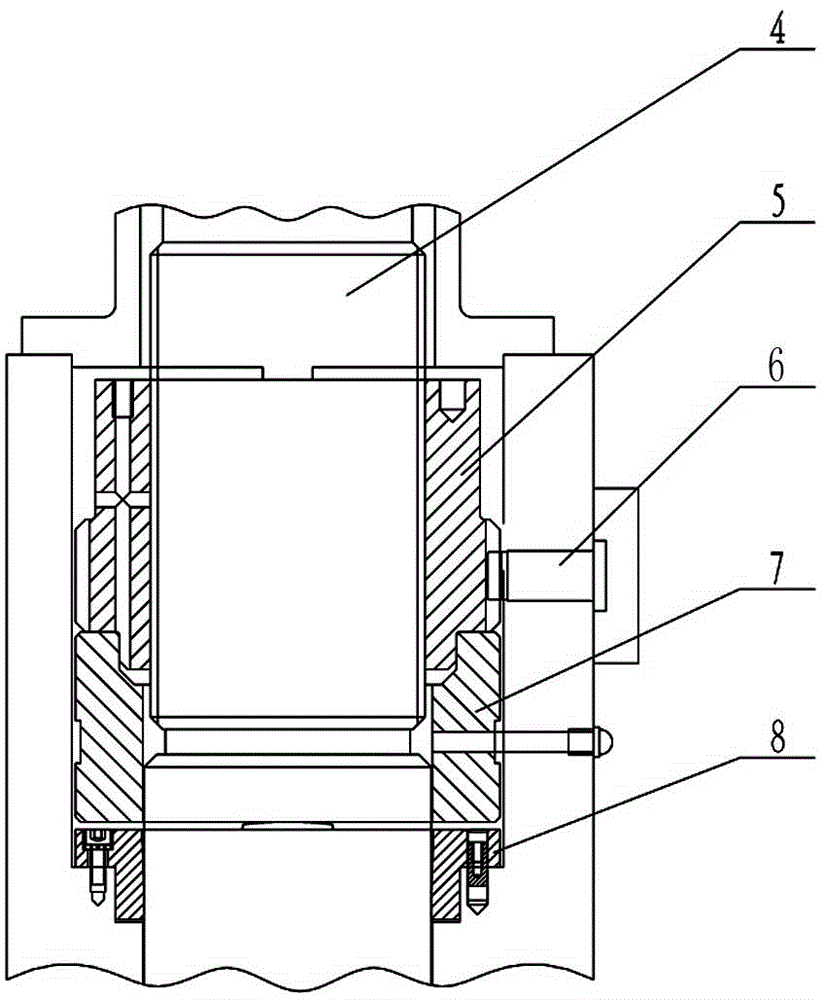

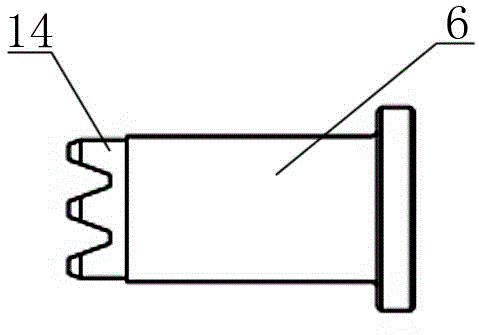

[0021] See attached Figure 1~6 , the present invention is a new type of roll gap adjustment device for a short stress line rolling mill, which is composed of a roll train device 3, a pull rod device 2 and a pressing device 1 using a spur gear as an output gear, the pull rod device 2 includes a pull rod 4, and the The pull rod 4 is provided with an adjusting nut 5, a pressure bearing sleeve 7 is provided below the adjustment nut 5, a spherical pad 8 is provided below the pressure sleeve 7, a pressure flange 10 is provided below the spherical pad 8, and the A locking pin 6 is arranged on the adjusting nut 5 , and the locking pin 6 is provided with a toothed head 14 . The joint between the roller system device 3 and the pull rod 4 is provided with a dust-proof ring gland 9 composed of a gland, an inner rotating shaft lip seal and an outer dust-proof ring to enhance its waterproof, oil, slag, and dust effects. Because the gear box of the pressing device of the existing roll gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com