Component pneumatic fastener machine

A fastener machine and component technology, which is applied in the directions of hand-held tools, portable mobile devices, manufacturing tools, etc., can solve problems such as difficulties in pneumatic nail pulling machines, implementation difficulties, structural conflicts, etc., to improve the use, save maintenance time, Easy to replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] According to the technical means of the present invention, the implementation modes suitable for the present invention are listed below and described in conjunction with the accompanying drawings as follows:

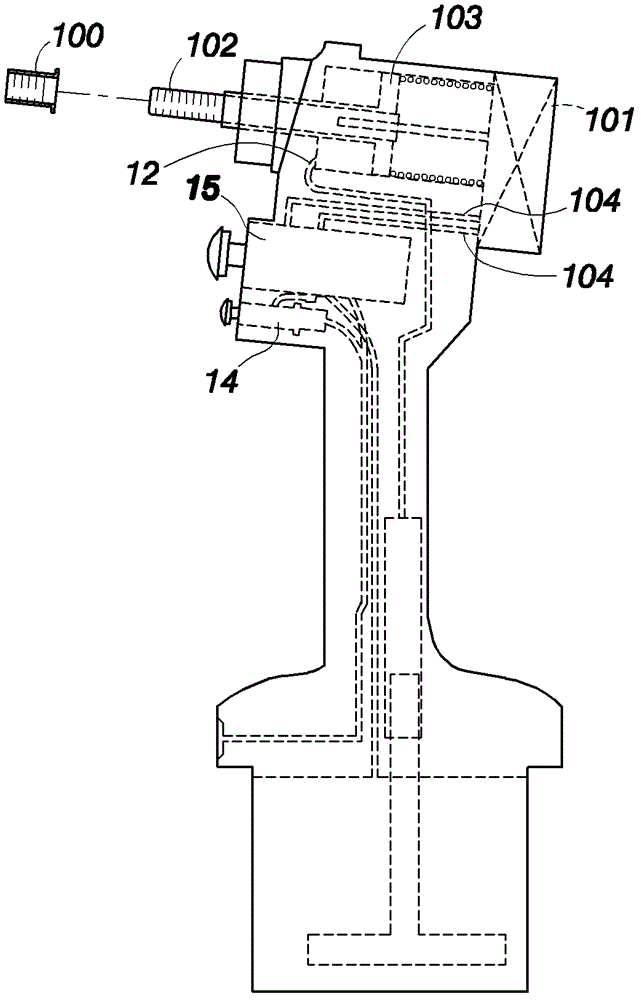

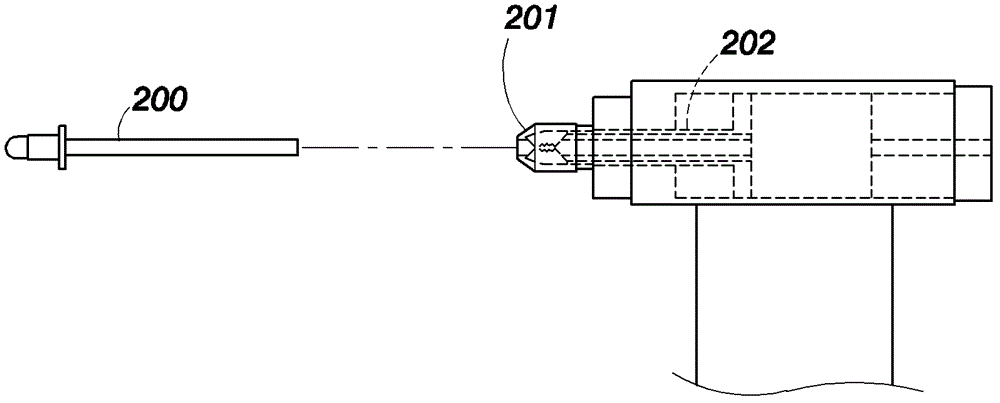

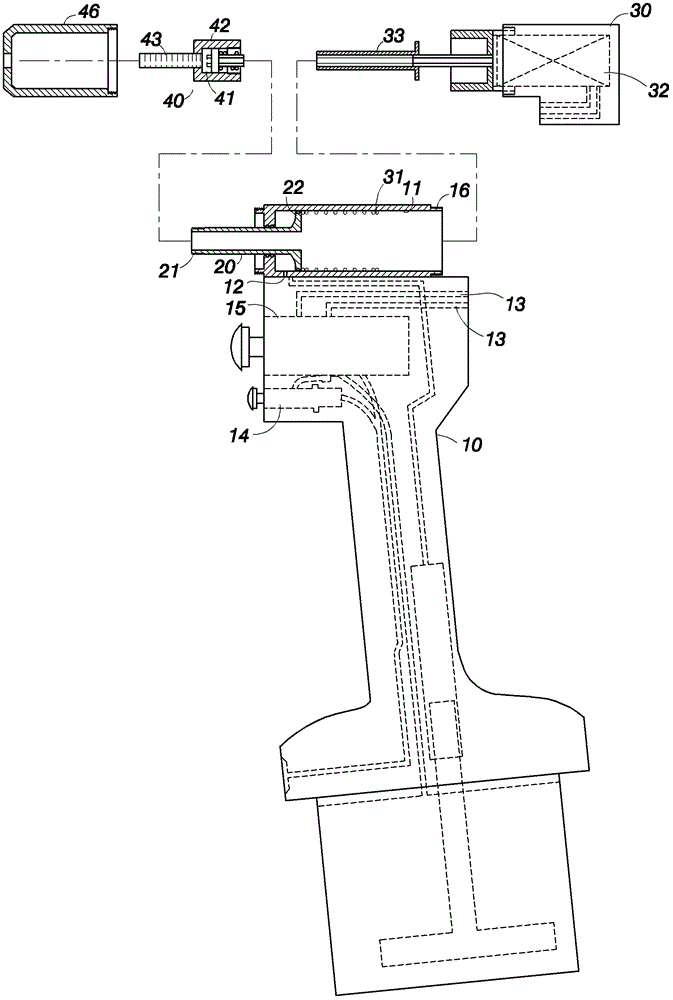

[0038] see image 3 and Figure 4 As shown, it is an exploded schematic view and a schematic cross-sectional view of the components of the first embodiment of the present invention. The figure discloses a component-type pneumatic fastener machine, which includes a body 10, a push rod 20, a first quick-release component 30 and a The second quick-release component 40, the first quick-release component 30 is used to cooperate with the body 10 to make the push rod 20 operate in a preset mode, the second quick-release component 40 cooperates with the push rod 20 for buckling Part positioning and deformation action, the first quick release component 30 and a second quick release component 40 shown in this embodiment are corresponding components for forming the pull cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com