High rotating type printing machine and rotating type printing method thereof

A technology of high-speed rotation and printing method, used in rotary printing presses, printing presses, screen printing presses, etc., can solve the problems of long waiting time for tiles, low printing efficiency, unfavorable market competition, etc., to improve printing production efficiency, reduce Cost, the effect that is conducive to market competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

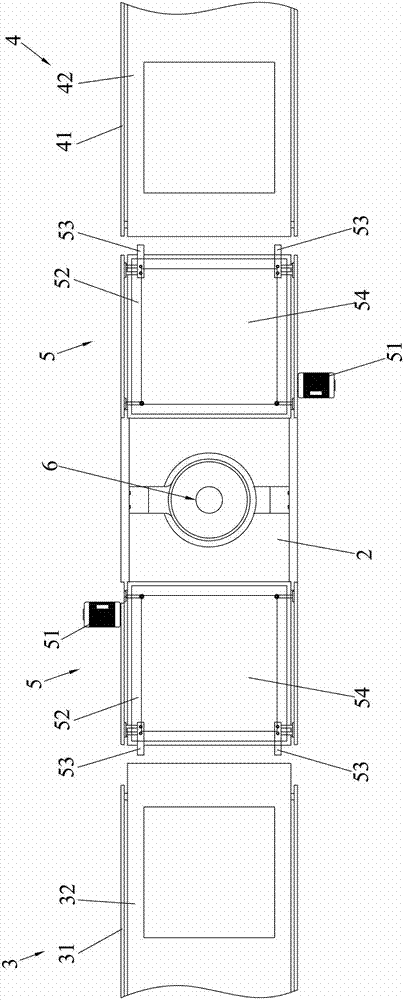

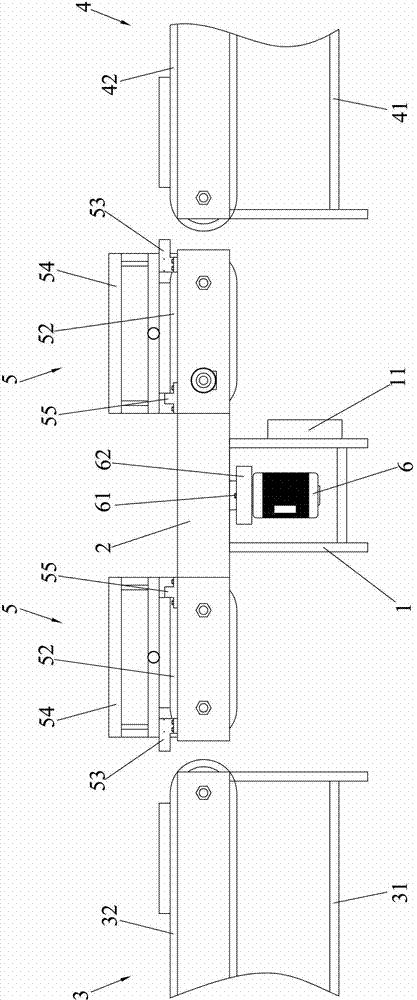

[0024] Please refer to Figure 1~2 As shown, a high-speed rotary printing machine includes a base 1, a turret 2 rotatably arranged on the pedestal 1, a feeding device 3 arranged on the front side of the turret 2, and a turret 2 arranged on the rotatable The discharge device 4 on the rear side of the frame 2, the turret 2 is evenly provided with a plurality of groups of printing components 5 for printing tiles along the circumferential direction, and the base 1 is provided with a rotary drive device 6, so The output end of the rotary driving device 6 is connected to the turret 2. In this embodiment, the printing components 5 have two groups, and the two groups of printing components 5 are symmetrically arranged on the turret 2. Of course, the printing components The number of 5 can be determined according to the actual situation and is not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com