Water-based ink lithographic offset printing method

A technology of lithographic offset printing and water-based ink, which is applied in printing, printing process, printing plate, etc., can solve environmental hazards and other problems, achieve the effect of improving printing production efficiency, reducing operating technical threshold, and improving printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 The metal plate base is directly processed into a super-hydrophobic surface

[0039] (1) Choose a superhydrophobic metal plate base, which can be aluminum plate base, zinc plate base, magnesium plate base or other metal plate bases.

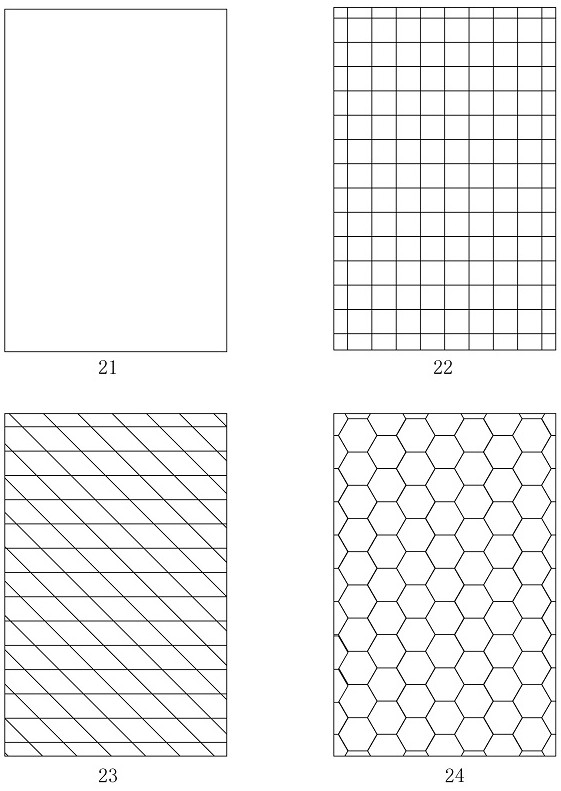

[0040] (2) The surface of the metal plate base can be treated with engraving, corrosion, laser, embossing and other processes to complete the strength support structure according to the needs, forming such as figure 2 Some patterns are shown.

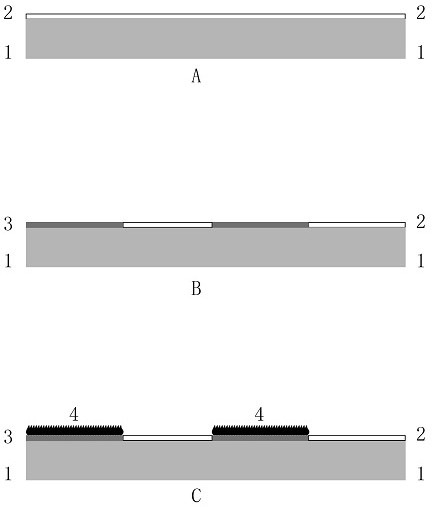

[0041](3) The super-hydrophobicity treatment of the surface of the metal plate base can be treated by direct chemical corrosion, anodic oxidation, micro-arc oxidation, laser direct treatment and other methods. After the surface of the metal plate base is super-hydrophobic, the surface contact angle of the material must be greater than or equal to 130° before it can be used in subsequent processes. Metal substrates treated with surface superhydrophobic properties such as figure 1 As sho...

Embodiment 2

[0048] Example 2 A layer of superhydrophobic material is coated on the surface of the metal plate base

[0049] (1) Choose a superhydrophobic metal plate base, which can be aluminum plate base, zinc plate base, magnesium plate base or other metal plate bases.

[0050] (2) The surface of the metal plate base can be treated with engraving, corrosion, laser, embossing and other processes to complete the strength support structure according to the needs, forming such as figure 2 Some patterns are shown.

[0051] (3) Super-hydrophobic treatment of the surface of the metal plate base, direct coating, soaking and other treatments, coating a layer of super-hydrophobic material on the surface of the metal plate base. After the surface of the metal plate base is super-hydrophobic, the surface contact angle of the material must be greater than or equal to 130° before it can be used in subsequent processes.

[0052] (4) Prepare UV-dried water-based ink, which is mainly composed of wate...

Embodiment 3

[0058] Example 3 A layer of superhydrophobic material is coated on the surface of the non-metal base

[0059] (1) Choose a super-hydrophobic non-metal base, which can be nylon, polyester, engineering plastic or other non-metal bases.

[0060] (2) Super-hydrophobic treatment of the surface of the non-metal base, direct coating, soaking and other treatments, coating a layer of super-hydrophobic material on the surface of the non-metal base. After the surface of the non-metallic plate base is super-hydrophobic treated, the surface contact angle of the material must be greater than or equal to 130° before it can be used in subsequent processes.

[0061] (3) Prepare UV-dried water-based ink, which is mainly composed of water-based resin, photoinitiator, pigment and additives.

[0062] (4) Replace part of the ink rollers on the lithographic offset printing equipment with anilox rollers.

[0063] (5) Cooling devices are added to the ink transfer roller, ink string roller, form roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com