Strong spring percussion type automobile safety hammer

A car safety, percussion technology, used in vehicle safety arrangements, pedestrian/occupant safety arrangements, hand hammers, etc., to solve problems such as misfortune

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

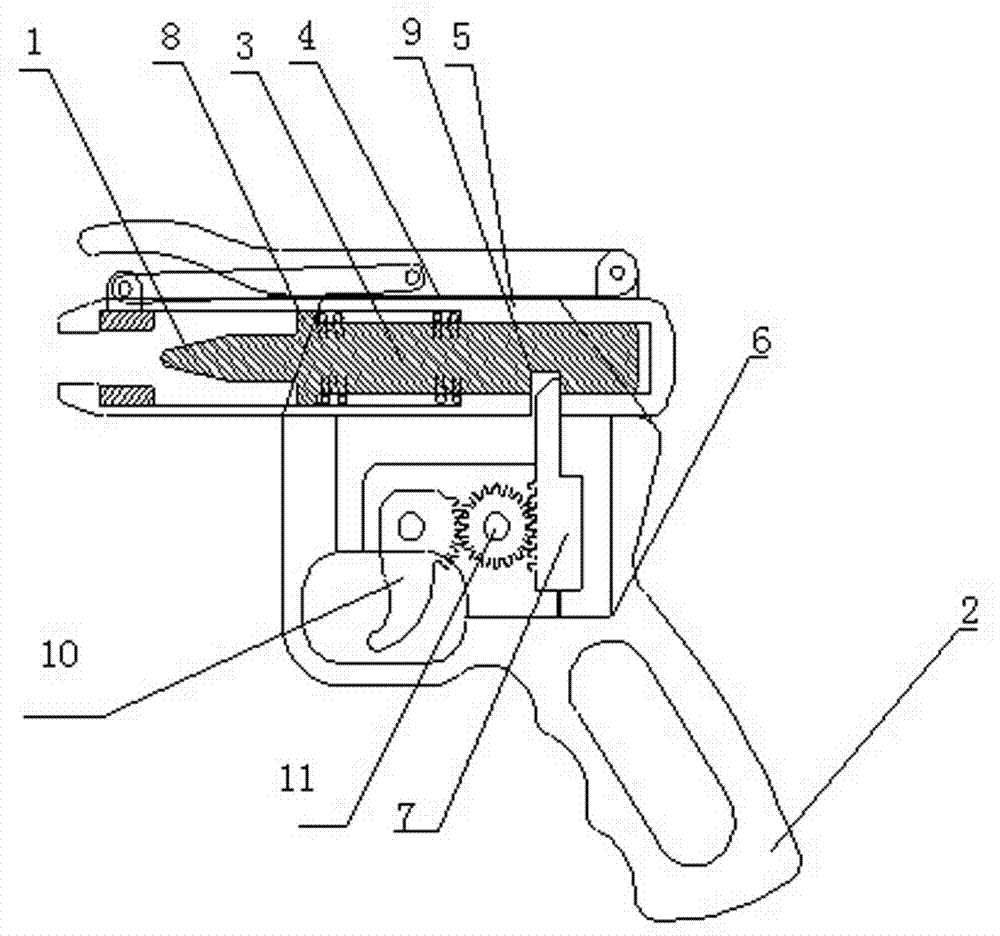

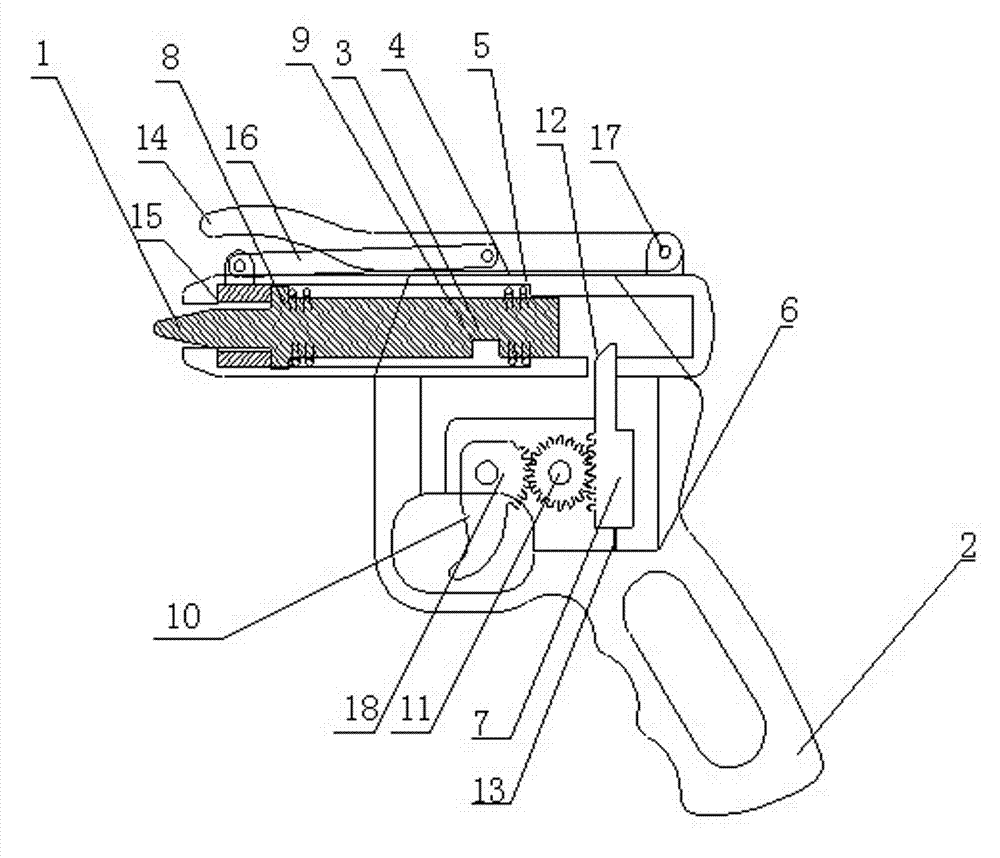

[0019] Example 1, such as figure 1 , figure 2 As shown, the present embodiment is a kind of automobile safety hammer that utilizes the percussion force of a spring. The safety hammer mainly includes a hammer head 1 made of hard alloy or diamond material. The hammer head 1 has a sharp point. In addition It also includes a hammer body 3 and a handle 2. When in use, the handle 2 is held, and the hammer head 1 is close to the window glass. In addition, this embodiment also includes a powerful spring 5 that drives the hammer body 3 and the hammer head 1 to strike forward. As shown in the figure, the hammer body 3 of this embodiment is a cylinder, and the powerful spring 5 is wrapped around the outer periphery of the hammer body , the hammer body 3 is provided with a protrusion 8 for installing a powerful spring 5 and a groove 9 for inserting the plug 7 . An overcoat 4 is also set outside the strong spring 5, and the strong spring 5 is fixed in the overcoat 4, as shown in Fig. f...

Embodiment 2

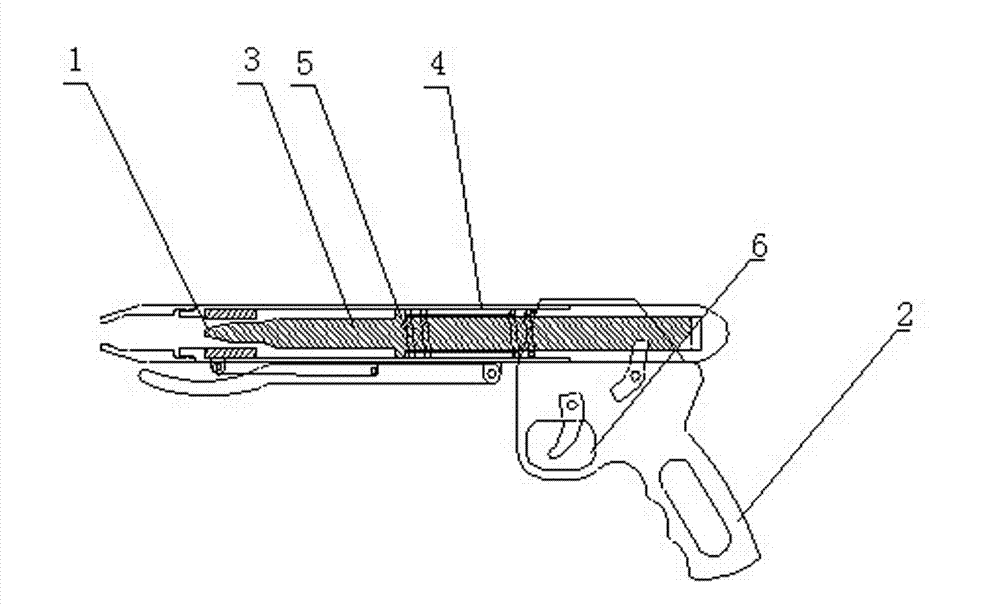

[0021] Example 2 as image 3 and Figure 4 As shown, the present embodiment is formed by reforming the fishing gun, mainly transforming the bullet of the fishing gun into a hammer head 1 of cemented carbide, especially diamond material, and setting a hammer shown in Embodiment 1 behind the bullet Body 3, a ring is set in the mouth of the gun barrel as a limit block 15 to limit the distance that the hammer head 1 protrudes when firing. This embodiment mainly uses the firing device and elastic device of the fishing gun, and has a built-in strong spring to withstand the alloy head. At the tail, the wrench is connected to the ring. Pull the wrench back to compress the spring to the bottom of the barrel. The trigger is connected to a hook. There is a groove behind the tip alloy. The iron hook compresses the spring behind the wrench. When the trigger is pressed, the groove of the pointed alloy is stuck so that it cannot move. When the trigger is pressed, the iron hook is separated ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap