Novel material picking method of aluminum extrusion machine rear portion finishing device

An aluminum extrusion and rear technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as belt damage, uneven force on the timing belt felt, and different elongation on both sides of the belt, so as to avoid The effect of belt damage, which is conducive to the continuity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

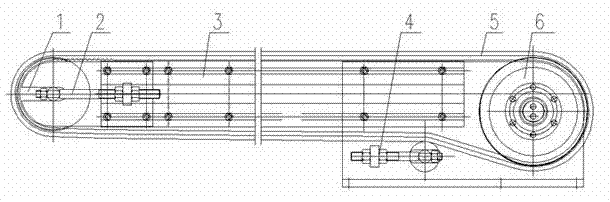

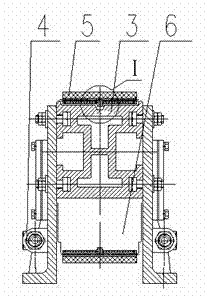

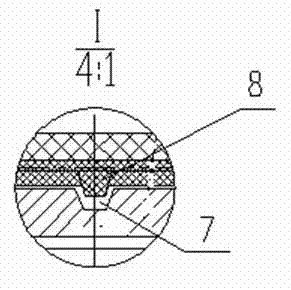

[0015] A new type of picking device for the rear finishing equipment of an aluminum extrusion machine, which includes: small synchronous pulley 1, small synchronous pulley end tensioning mechanism 2, aluminum beam 3, large synchronous pulley end tensioning mechanism 4, and synchronous belt 5 1. Large synchronous pulley 6; It is characterized in that: the middle of the upper surface of the aluminum beam 3, the circumferential middle of the large synchronous pulley 6 and the circumferential middle of the small synchronous pulley 1 are all provided with a guide groove 7, and the upper surface of the synchronous belt 5 A guide belt 8 with protrusions is arranged in the middle, and the protrusions on the guide belt 8 correspond to the guide grooves 7 .

Embodiment 2

[0017] Such as figure 1 As shown, the new material picking device for the rear finishing equipment of the aluminum extrusion machine includes: small synchronous pulley 1, small synchronous pulley end tensioning mechanism 2, aluminum beam 3, large synchronous pulley end tensioning mechanism 4, Synchronous belt 5, large synchronous pulley 6; large synchronous pulley 6 with guide groove is fixed on one end of aluminum beam 3 with guide groove through a splint, and the bottom of aluminum beam 3 with guide groove is close to large synchronous pulley 6 with guide groove On the side, a large synchronous pulley end tensioning mechanism 4 is installed, which is composed of a guide wheel, a threaded push rod and a nut. The small synchronous pulley 1 with guide groove is installed on the other end of the aluminum beam 3 with guide groove through a splint, and the small synchronous pulley 1 with guide groove has a small synchronous pulley end tensioning mechanism 2 on the wheel shaft. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com