Steel plate pressing guide device

A technology of guide device and steel plate, applied in the direction of guide/positioning/alignment device, etc., can solve the problems of uneven surface, deviation of steel plate, damage to rollers, etc., to improve work reliability, prolong service life, and facilitate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

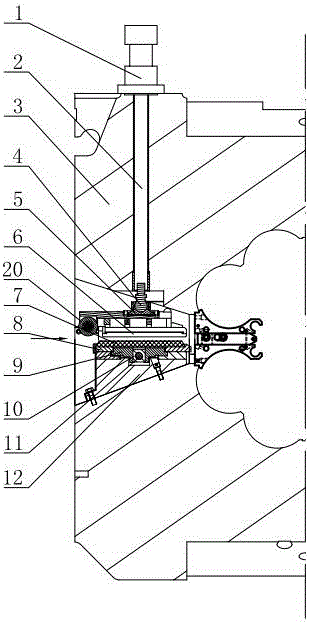

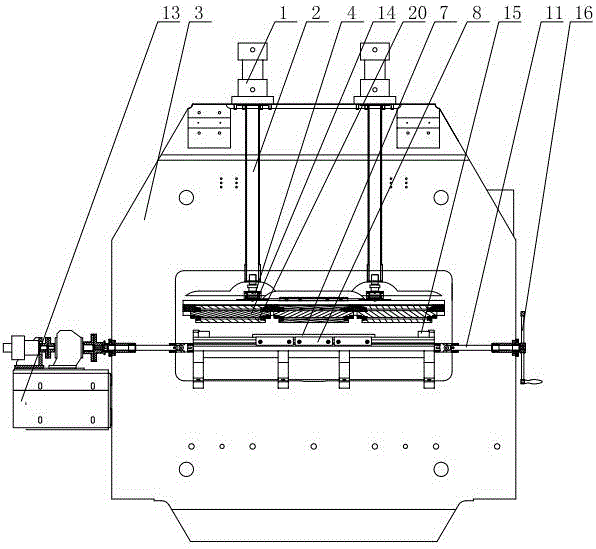

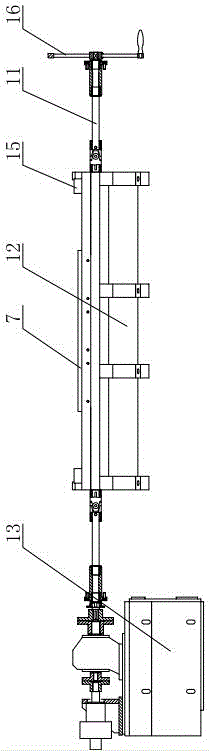

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the steel plate depressing guide device of this embodiment includes a main rolling mill shell 3, the middle part of the main rolling mill shell 3 is provided with a roll system installation hole, and the main rolling mill shell 3 on the side of the roll system installation hole is provided with a horizontally arranged Tapered groove, the upper part of the tapered groove is the upper support seat, and the lower part is the lower support seat 19; an oil cylinder 1 is installed on the top of the main rolling mill shell 3, and the piston rod 2 of the oil cylinder 1 extends into the main rolling mill shell 3 to the upper support seat. And at the bottom of the upper support base, a spherical strut 4 is installed through the bearing 5, the spherical strut 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com