Floor tile packing box loading equipment

A packaging box and equipment technology, applied in the field of floor tile packaging box loading equipment, can solve the problems of high labor intensity, low loading efficiency, increased labor cost, etc., and achieve the goal of reducing labor intensity, improving loading efficiency and reducing labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

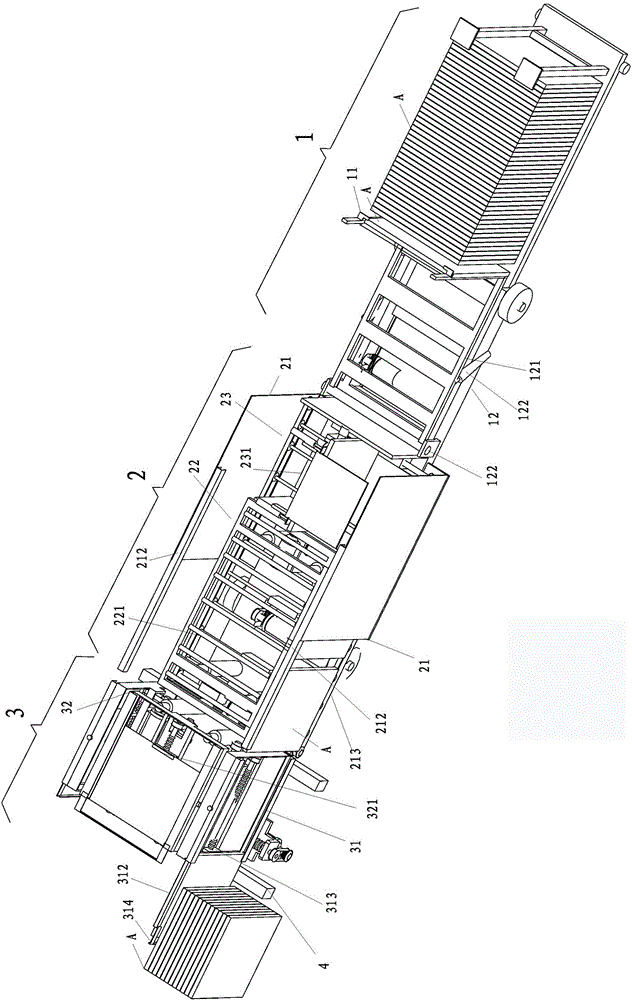

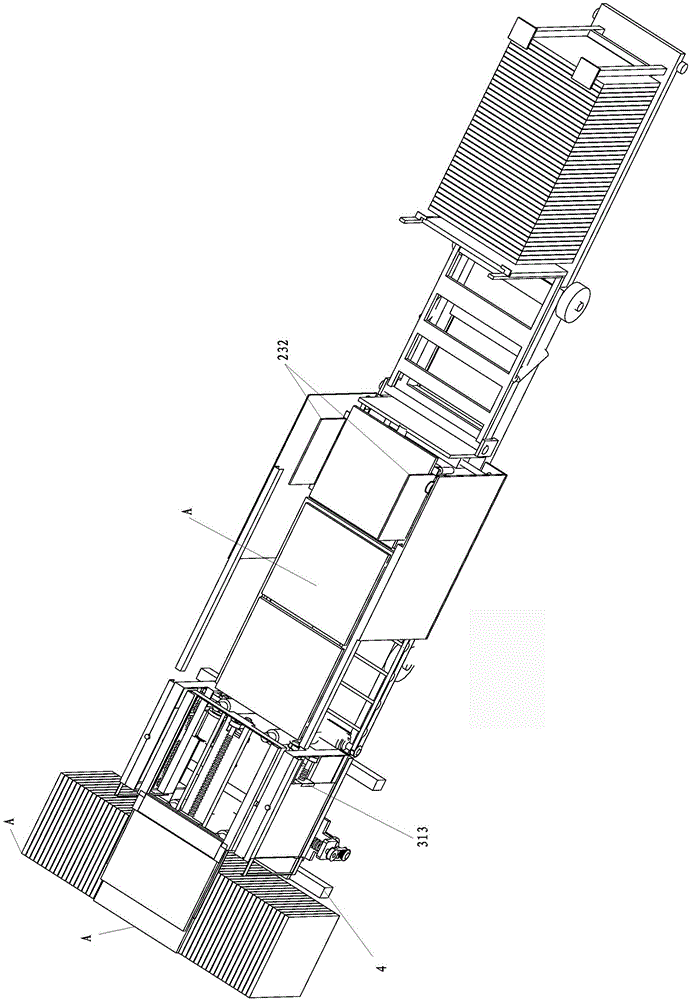

[0017] The present invention is a self-developed floor tile packaging box (hereinafter referred to as box) loading equipment (taking 1000*1000 floor tiles as an example, each box contains 2 pieces of floor tiles, with a total weight of 60 kg; the first layer of boxes is placed vertically , the second layer of boxes is placed flat, and the container of common specifications is 2.4m wide and 5-6m long, about 400 boxes).

[0018] like figure 1 Shown, a kind of floor tile packing case loading equipment, it comprises the box taking device 1 that is connected with each other, conveying device 2 and box putting device 3; 11 The clamped case A is put on the conveying device 2; in this embodiment, the conveying structure 12 of the case taking device 1 is a support 121 connected to the bottom of the clamp 11, and the support 121 is provided with a rotating shaft 122, and the support 121 A power device 123 is connected, and the support 121 can be erected by using the power device, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com