Viscosity index improver composition and application thereof

A viscosity index and improver technology, applied in lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

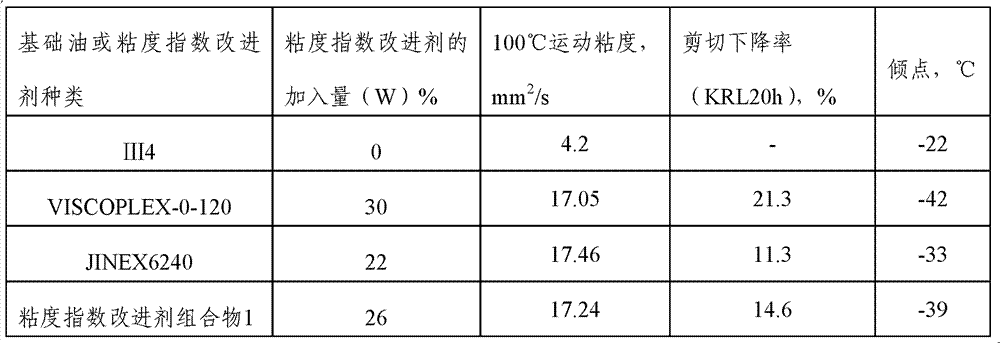

[0026] Mix polymethacrylate, polyisobutylene and base oil in a mass ratio of 50:50:0, and stir them uniformly at 80°C with mechanical or manual stirring to prepare viscosity index improver composition 1, in which polymethyl The main component of acrylate type viscosity index improver is polymethacrylate (VISCOPLEX-0-120, molecular weight about 40000), and the main component of polyisobutylene type viscosity index improver is polyisobutylene (JINEX6240, molecular weight about 2400). The obtained viscosity index improver composition 1 is added in the III4 hydrogenated base oil according to the amount of 26%, and the 100 ℃ kinematic viscosity of the oil product, the shear decline rate (KRL test 20h) and the pour point are measured. In addition, the Add polymethacrylate (VISCOPLEX-0-120) to III4 hydrogenated base oil and add polyisobutylene poly(JINEX6240) oil to III4 hydrogenated base oil for determination. The test results are shown in Table 1.

[0027] Table 1 Viscosity Index I...

Embodiment 2

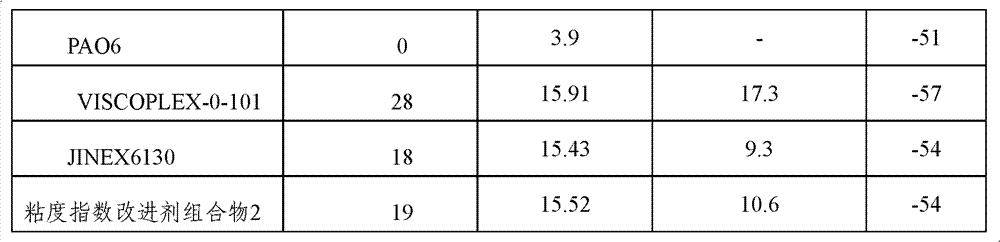

[0033] Mix polymethacrylate, polyisobutylene and base oil in a mass ratio of 10:80:10, and stir them evenly by mechanical or manual at 90°C to prepare viscosity index improver composition 2, in which polymethyl The main component of acrylate type viscosity index improver is polymethacrylate (VISCOPLEX-0-101, molecular weight about 30000), the main component of polyisobutylene type viscosity index improver is polyisobutylene (JINEX6130, molecular weight about 1300), the base oil is Group II 6 hydrogenated base oil. The viscosity index improver composition 2 that will obtain is joined in the PAO6 synthetic base oil according to the amount of 19%, and the 100 ℃ kinematic viscosity of measuring oil product, shear rate of decline (KRL test 20h) and pour point, in addition, also to PAO6 Polymethacrylate (VISCOPLEX-0-101) was added to the synthetic base oil and polyisobutylene poly(JINEX6130) oil was added to the PAO6 synthetic base oil for determination. The test results are shown i...

Embodiment 3

[0041] Mix polymethacrylate, polyisobutylene and base oil in a mass ratio of 80:10:10, and stir them uniformly at 70°C with mechanical or manual stirring to prepare viscosity index improver composition 3, in which polymethyl The main component of acrylate type viscosity index improver is polymethacrylate (LUBRIZOL 7702, molecular weight about 30000), the main component of polyisobutylene type viscosity index improver is polyisobutylene (LUBRIZOL 3174, molecular weight about 1500), and the base oil is type III 6 Hydrogenated base oil. The resulting viscosity index improver composition 3 was added to Type III 6 hydrogenated base oil in an amount of 25%, and the kinematic viscosity at 100° C., shear drop rate (KRL test 20h) and pour point of the oil were measured. In addition, The addition of polymethacrylate (LUBRIZOL 7702) to Type III 6 hydrogenated base oil and the addition of polyisobutylene poly(LUBRIZOL 3174) to Type III 6 hydrogenated base oil were also tested. The test re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com