Steel strand combing and bundling production line

A technology for production lines and steel strands, which is used in braids, textiles and papermaking, etc., can solve the problems of construction progress, tension fractures, and poor prestressed tensioning effects of steel strands, so as to improve efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

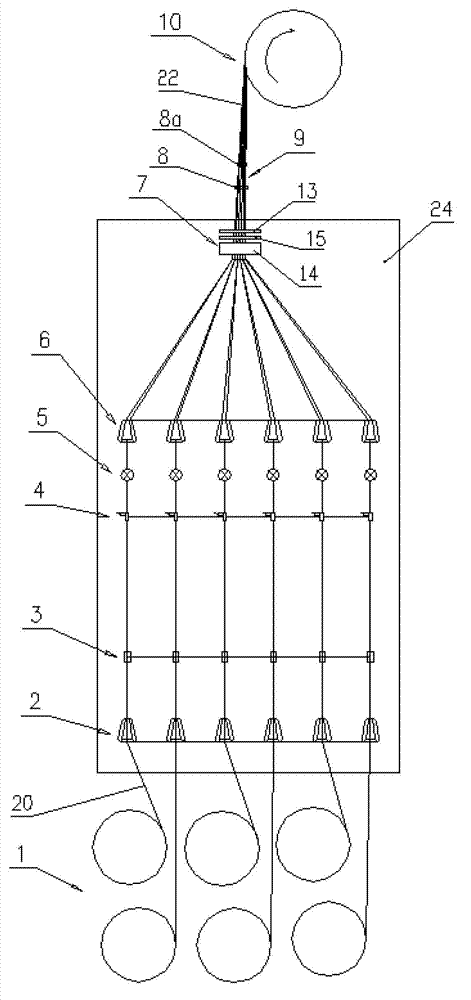

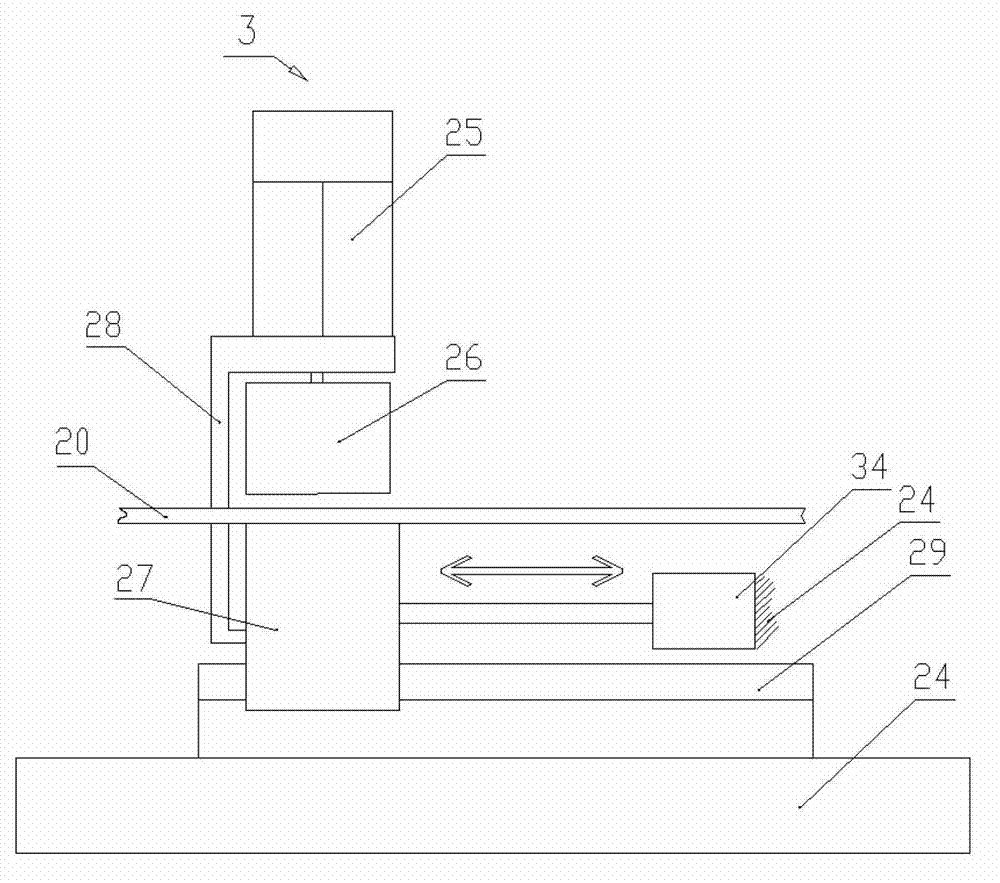

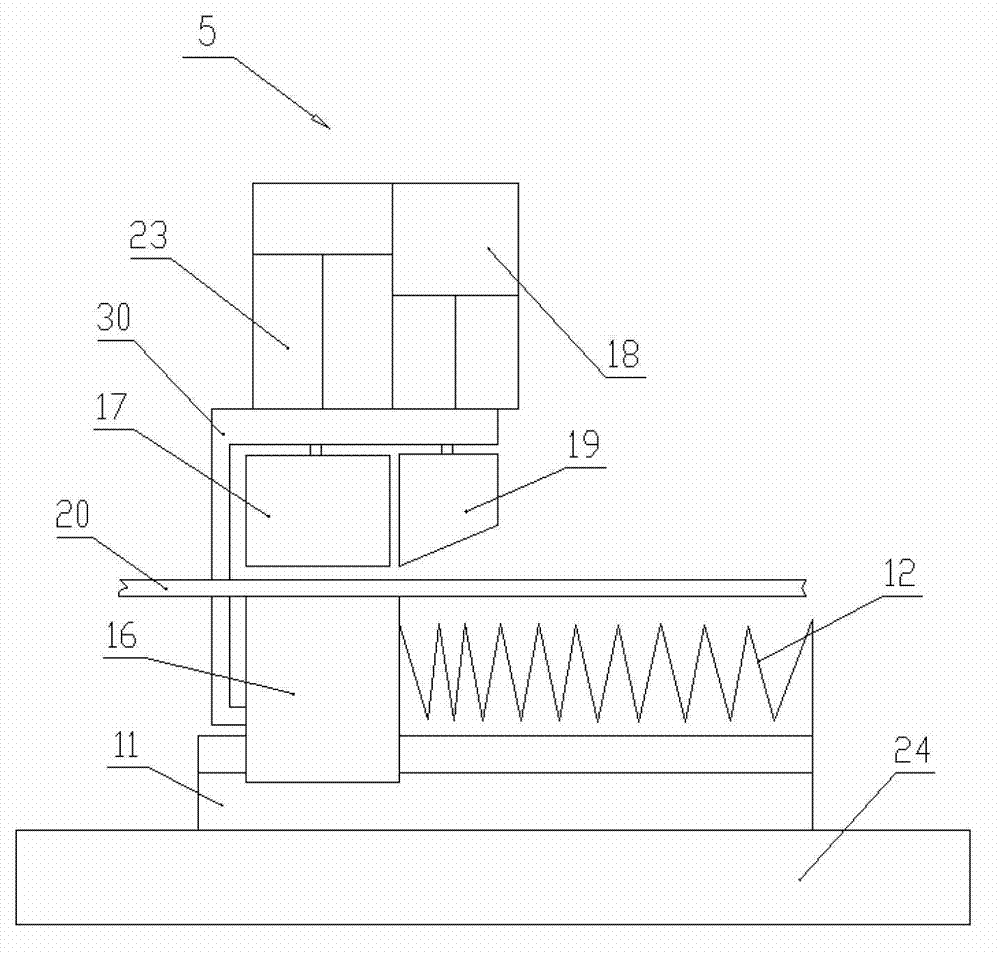

[0017] As shown in the figure, the present invention provides a production line for combing and braiding of steel strands. The production line for combing and braiding of steel strands includes: a plurality of pay-off reels 1 equipped with steel strands 20 arranged side by side, each pay-off reel After the single steel strand 20 in 1 passes through the wire management mechanism 2, the clamping and feeding mechanism 3, the counting mechanism 4, the cutting mechanism 5, and the wire mechanism 6, which are arranged in parallel in the axial direction and have the same structure, the multiple steel strands Stranded wires 20 collectively pass through the threading mechanism 7 and the binding mechanism 9 positioned behind the threading mechanism 7 , and the steel strand braided bundle 22 bundled by the binding mechanism 9 is wound on the reel of the winding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com