A Method for Reinforcement of Thin Coal Pillars between Multi-lane and Down-Trough Lanes

A technology of thin coal pillars and coal pillars, which is applied in the field of reinforcement of thin coal pillars between multi-lane and channel lanes, can solve the problems of wasting coal resources, difficult maintenance, and excessive coal pressure, and achieves simple maintenance, improved lateral constraints, and improved strength and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

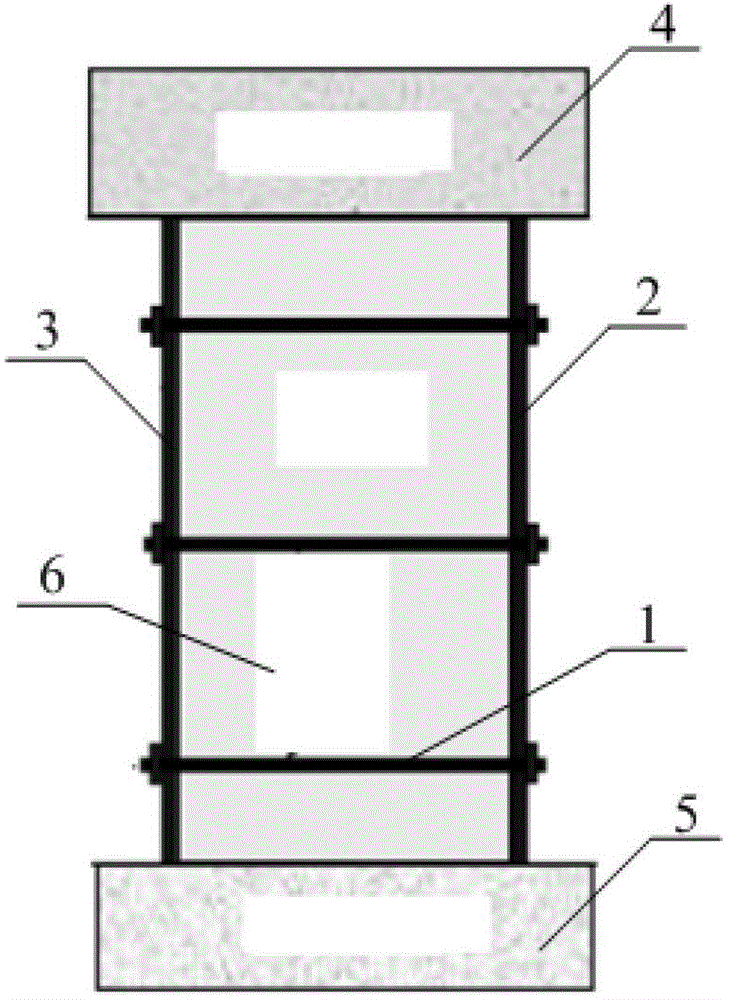

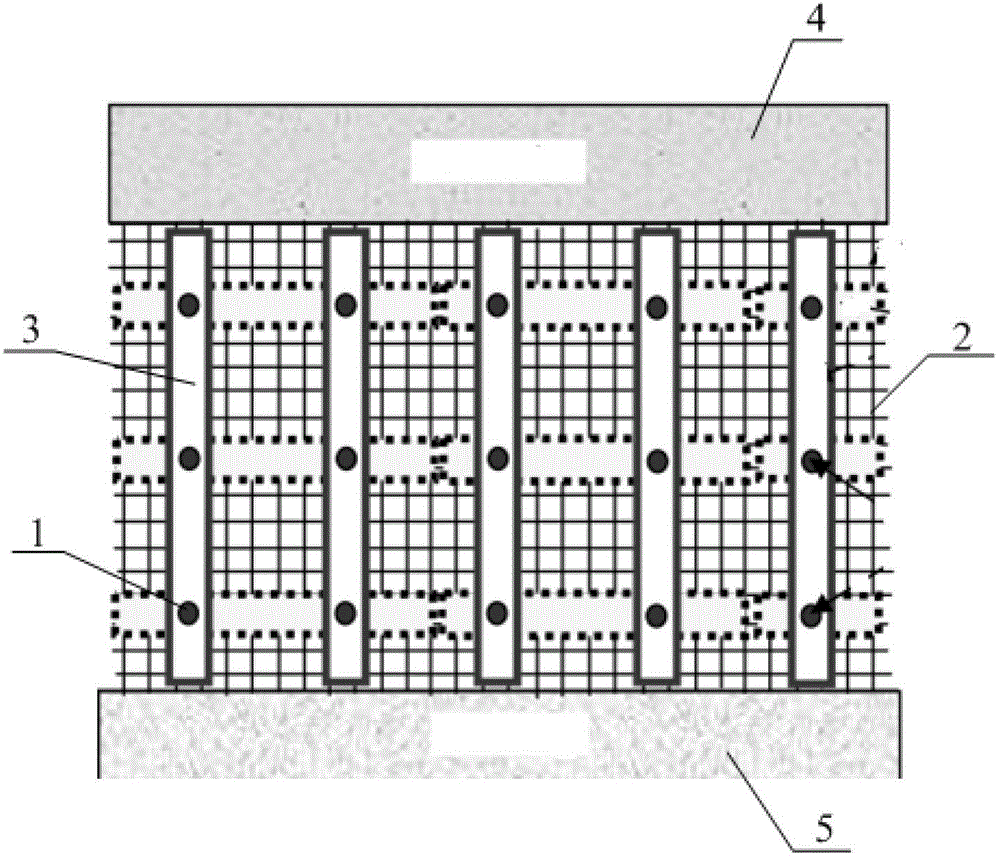

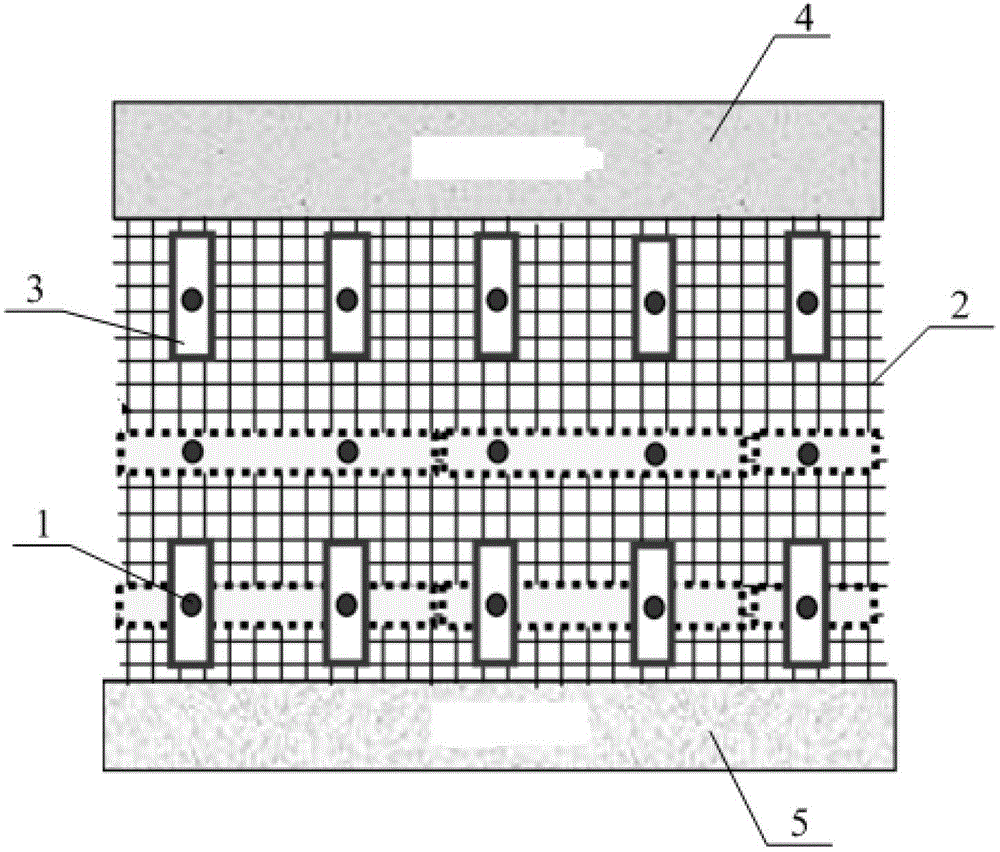

[0030] The object of the present invention is to provide a method for reinforcing thin coal pillars 6 between multi-lane tunnel lanes. The method first drills holes on the coal pillar 6 face of a roadway and penetrates the coal pillar 6, penetrates the reinforcement material 1, and then Hang the mesh 2 and the steel belt 3 on both sides of the coal pillar 6, apply a pre-tightening force to the reinforcement 1 and lock it, and tightly connect the mesh 2 and the steel belt 3 into a whole to realize the alignment of the coal pillar 6. Apply lateral pressure.

[0031] In the embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com