Damp lashing strip structure of industrial steam turbine high load short vane

An industrial steam turbine, high-load technology, applied in the directions of blade support elements, mechanical equipment, engine elements, etc., can solve the problems of difficult damping shroud design and high damping requirements, and achieve the strength and vibration performance, tangential stiffness is large, increase Effect of Circumferential Length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

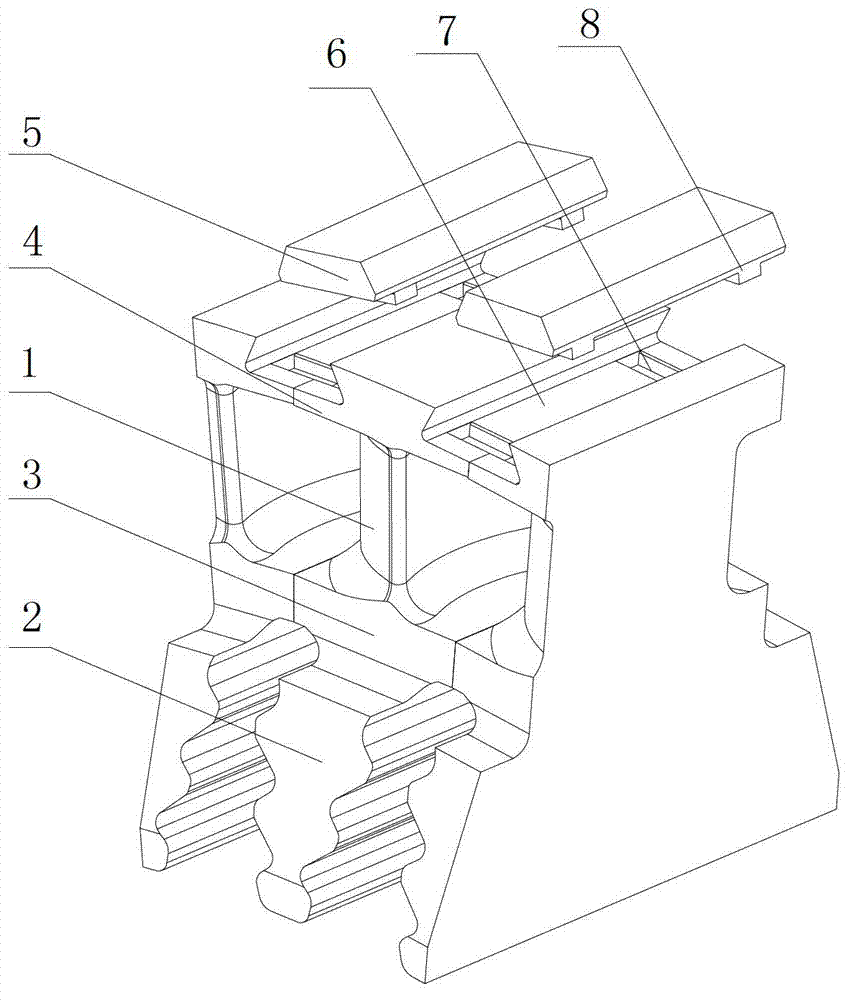

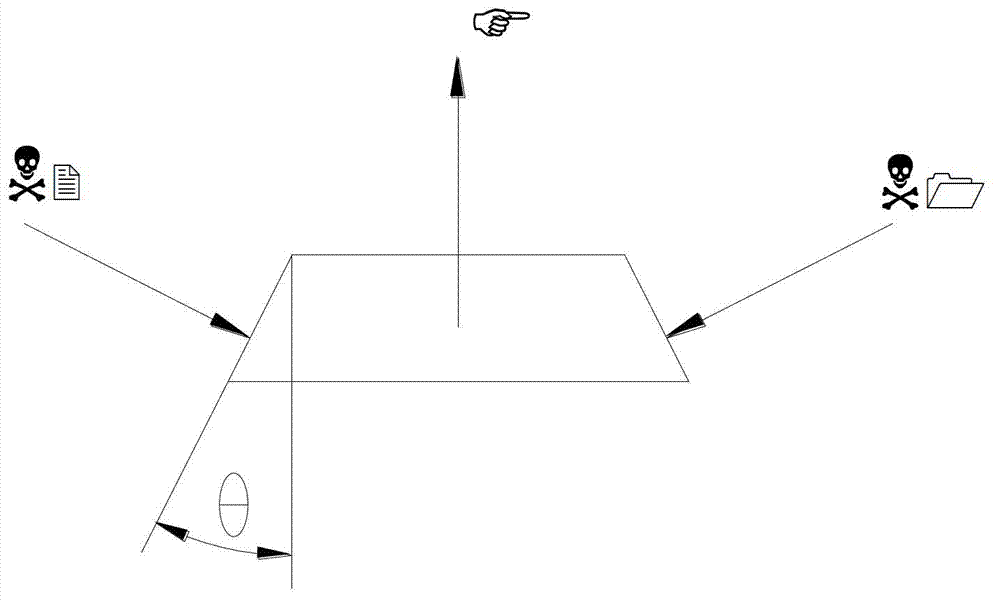

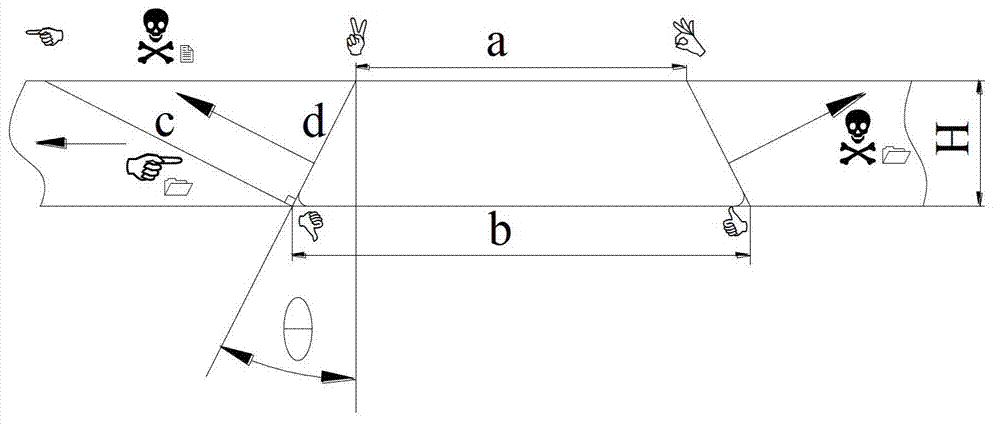

[0014] Such as figure 1 As shown, the damping shroud 4 structure of the high-load short blade of the industrial steam turbine described in this embodiment, the blade is composed of the blade body 1, the blade root 2 and the intermediate connecting body 3, and the whole circle of blades is uniformly installed on the blade root 2 in the circumferential direction. On the rotor, a shroud 4 is provided on the top of the airfoil 1, and the shrouds 4 on two adjacent blades in the circumferential direction are arranged close to each other, and an axial wedge-shaped groove 6 is milled on the mating surface of the two adjacent shrouds 4. 6 is provided with wedge-shaped damping block 5.

[0015] Circumferential sealing grooves 7 are respectively provided at both ends of the bottom of the wedge-shaped groove 6 , and sealing shoulders 8 are provided on the corresponding positions of the sealing grooves 7 on the wedge-shaped damping block 5 .

[0016] As an optimization, the wedge angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com