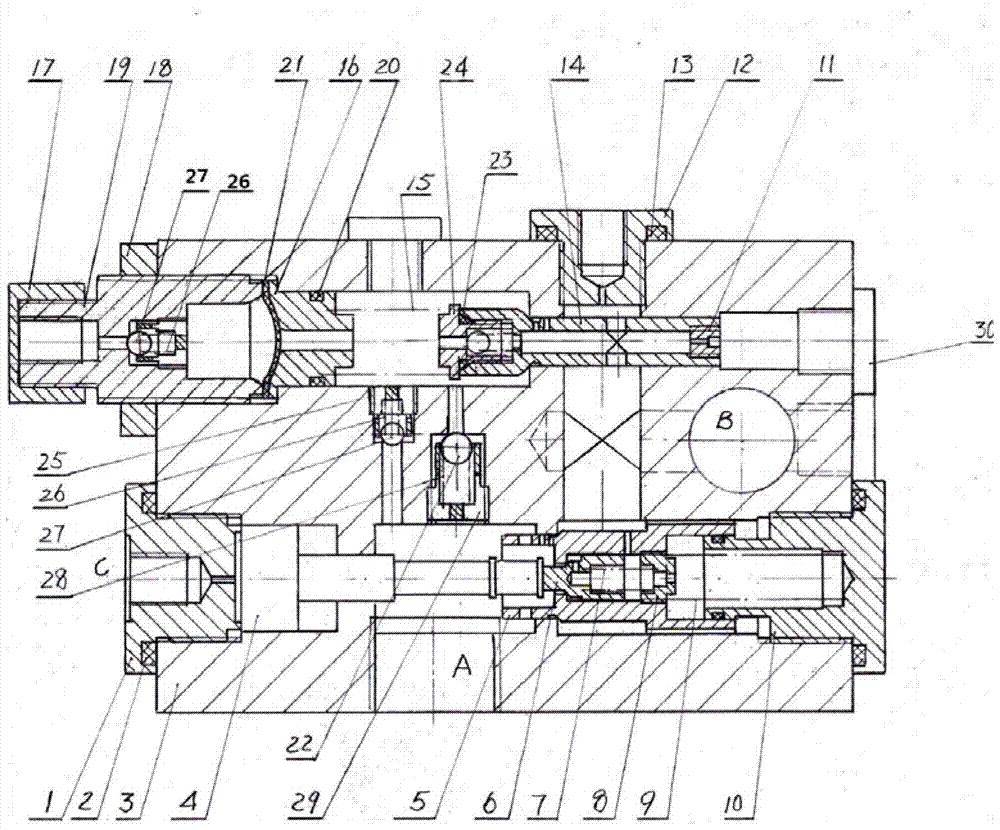

Balance valve of dynamic load differential pressure protection and flow pressure air chamber compensation

A technology of flow pressure and balance valve, applied in the field of balance valve, which can solve the problems of pressure loss and energy consumption, system heating, uncontrolled drop of the boom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the balance valve of the present invention is: Sealing working condition: the high-pressure oil in chamber B passes through the small hole at the right end of the main valve core 5, and communicates with the spring chamber at the right end of the main valve core 5, and the one-way valve core 6 is connected with the main valve core. The cores 5 are all locked with their sealing seats under the action of the high-pressure oil and their respective springs, closing the flow channel of the high-pressure oil in the B cavity to the A cavity. The hydraulic oil flows from chamber A to chamber B, the one-way valve core 6 is closed under the action of the small spring 7, the right chamber of the main valve core 5 is in communication with chamber B, and the hydraulic oil in chamber A pushes the main valve core 5 together with the one-way spool 6 compresses the main spring 9 to move to the right, the throttle hole on the small cylindrical sleeve at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com