High temperature resistant guide rail roller

A technology of high temperature resistance and guide rails, which is applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of inapplicability, few types of guide rail rollers, etc., and achieve the effect of preventing work deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

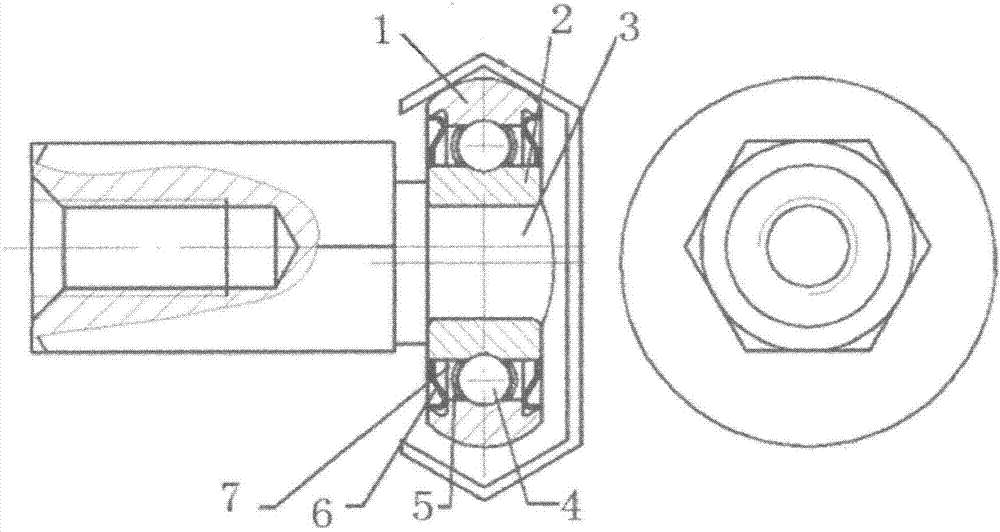

[0008] Attached below figure 1 The present invention will be further described in detail with specific embodiments.

[0009] The high temperature-resistant guide rail roller includes an outer ring 1, an inner ring 2, an eccentric shaft 3, a rolling element 4, a cage 5, a dust cover 6 and a high-temperature grease 7. The outer circle of the outer ring 1 is arc-shaped and runs On the V-shaped guide rail, two effective points are the contact between the guide rail and the outer circle of the outer ring 1. The inner ring 2 is riveted on the eccentric shaft 3, and the screw hole for the tail of the eccentric shaft 3 is connected to the The inner ring installed on the head of the eccentric shaft is not concentric, so that the outer ring 1 is in the guide rail, which is easy to install, and the preload required by the guide rail can be obtained through convenient adjustment. The rolling element 4 is made of ceramics , is spherical, the cage 5 is made of high-quality brass strips, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com