A high-temperature pressure sensor back-end packaging structure and a packaging method

A pressure sensor and high-temperature technology, applied in the direction of microstructure devices, manufacturing microstructure devices, microstructure technology, etc., can solve problems such as heat failure, failure to work normally, unreasonable structure, etc., to reduce heat conduction, prevent oxidation failure or damage External interference, reduce the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

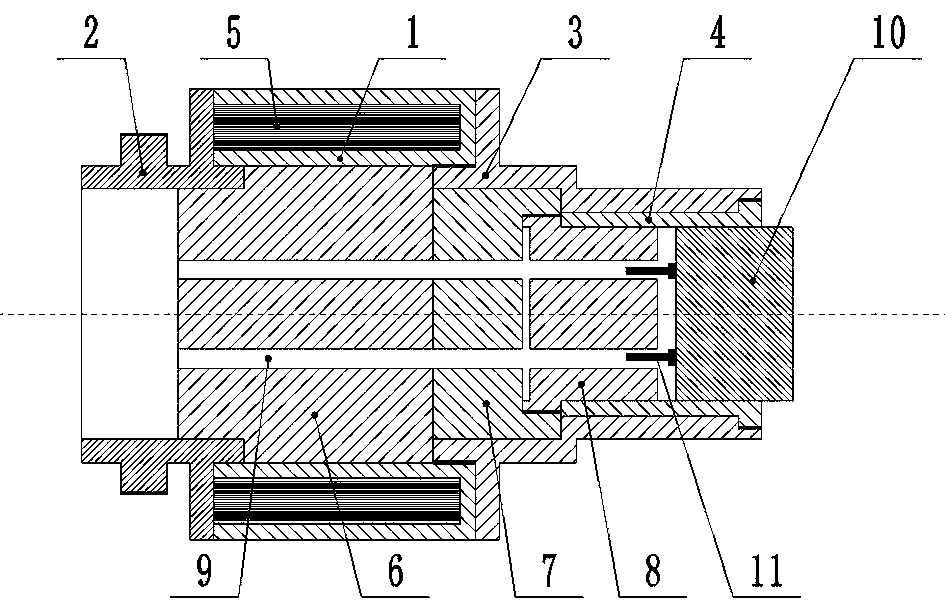

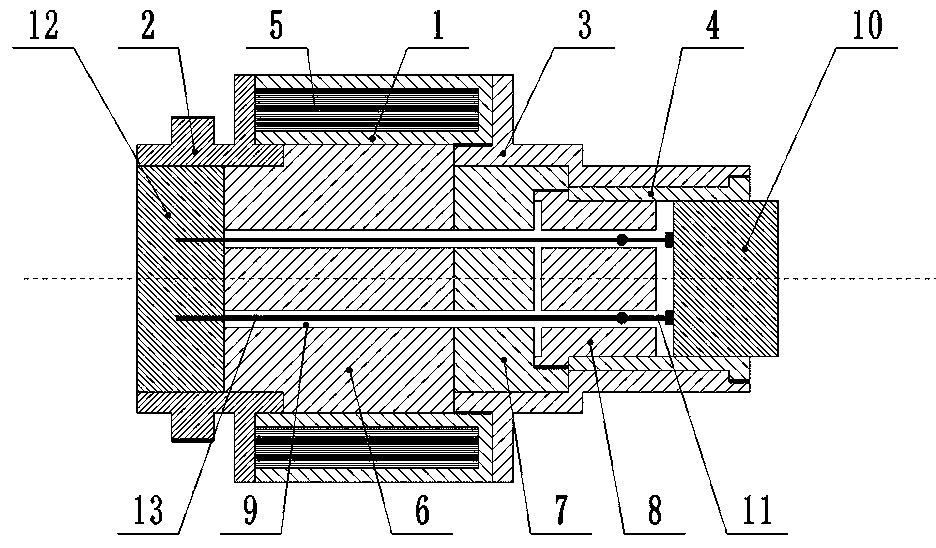

[0031] Such as figure 1 As shown, a back-end packaging structure of a high-temperature pressure sensor includes a threaded connector 2, a cylindrical shell 1, a cable fixing head 3 and a fastening nut 4 assembled on the same axis in sequence, the threaded connector 2, the cable fixing Both the head 3 and the fastening nut 4 are provided with axial through holes; the middle part of the cylindrical shell 1 is a through inner cavity, and the shell wall of the cylindrical shell 1 is designed as a vacuum interlayer, and one end of the interlayer is open ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com