Diaphragm positioning structure and backlight module thereof

A positioning structure and diaphragm technology, applied in the direction of optics, electric light source, light source fixing, etc., can solve the problems of diaphragm warping and deformation, and achieve the effect of improving optical taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

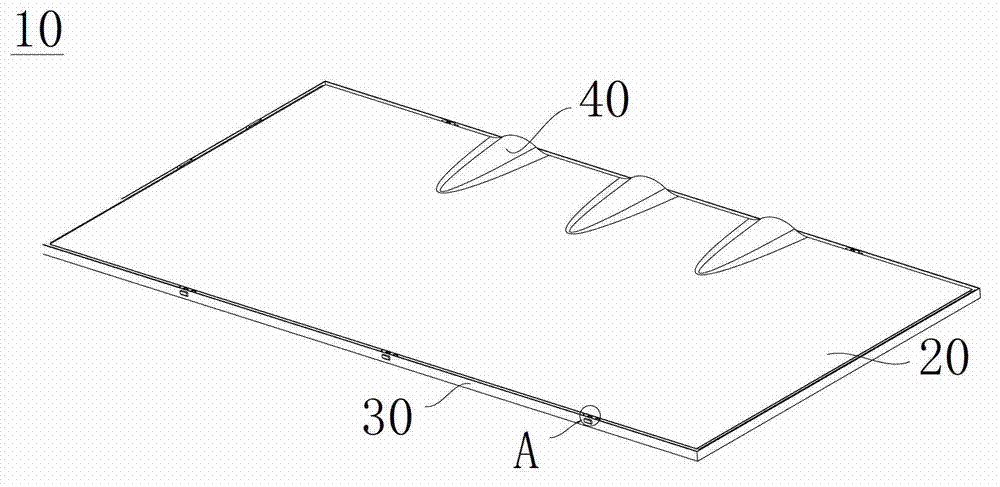

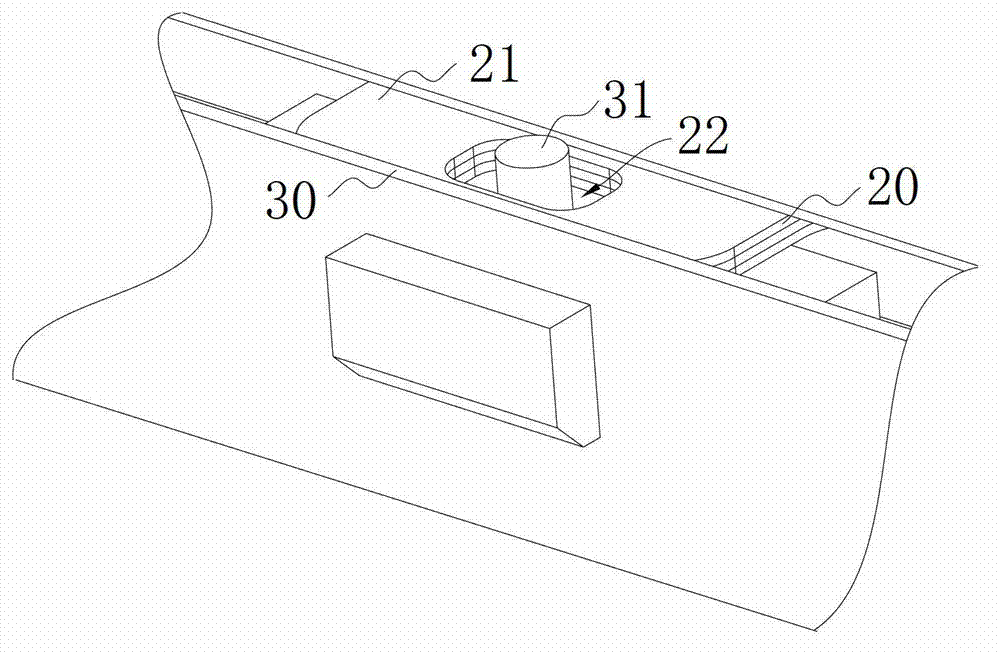

[0034] Please refer to Figure 3 to Figure 7 , the backlight module of the present invention is used in display devices, such as Figure 4 As shown, the backlight module 100 includes a film positioning structure 200 , a light guide plate 300 fixed in the film positioning structure 200 , and a backlight (not shown). The diaphragm positioning structure 200 includes a diaphragm 210, a positioning frame 220 and a slider 250, wherein the diaphragm 210 is an optical diaphragm, and the function of the optical diaphragm is to improve the optical uniformity of the backlight module 100 in the liquid crystal display device, so that the backlight The module 100 can generate the best light source distribution and improve the image quality. In this embodiment, the edge of the diaphragm 210 has at least one lug 211 , and a positioning hole 212 is formed in the middle of the lug 211 , wherein the positioning hole 212 is a perforation.

[0035] In a liquid crystal display device, usually a p...

Embodiment 2

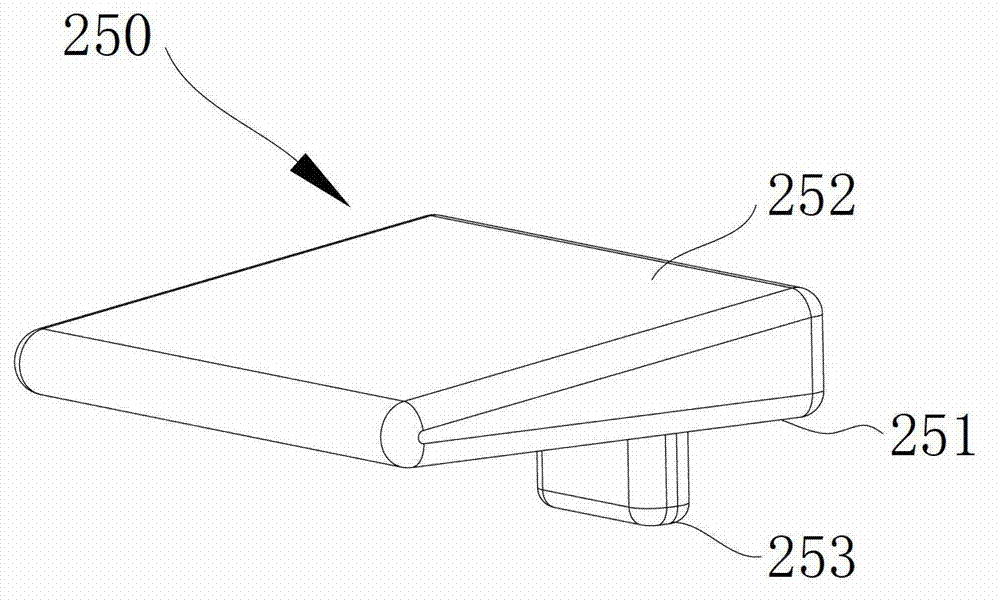

[0041] Please refer to Figure 8 to Figure 12 , only the differences between Embodiment 2 and Embodiment 1 will be described below. Such as Figure 9 As shown, in Embodiment 2, the difference is that the positioning frame 220 not only includes the back frame 230 and the plastic frame 240, but also includes an insert block 243 with a slope, and the insert block 243 is arranged on the lower surface of the top plate 241, The slope of the inserting block 243 is the first slope 242 . Wherein, in order to better control the sliding direction and sliding distance of the sliding block 250 , a positioning slide groove 270 is formed on the bottom plate 231 so that the sliding block 250 can slide toward a preset track. In order to realize the purpose that the slider 250 can slide to the preset track, especially, as Figure 8 As shown, the slider 250 is provided with a corresponding engaging protrusion 260 on the bottom surface 251, and the positioning protrusion 253 is disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com