Solid-liquid power sounding rocket land launching sequential control system

A timing control, sounding rocket technology, applied in the field of control systems, can solve the problems of difficult movement, cumbersome procedures, complex structure, etc., to achieve the effect of remote safe and reliable ignition, avoid danger, and ensure smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with accompanying drawings.

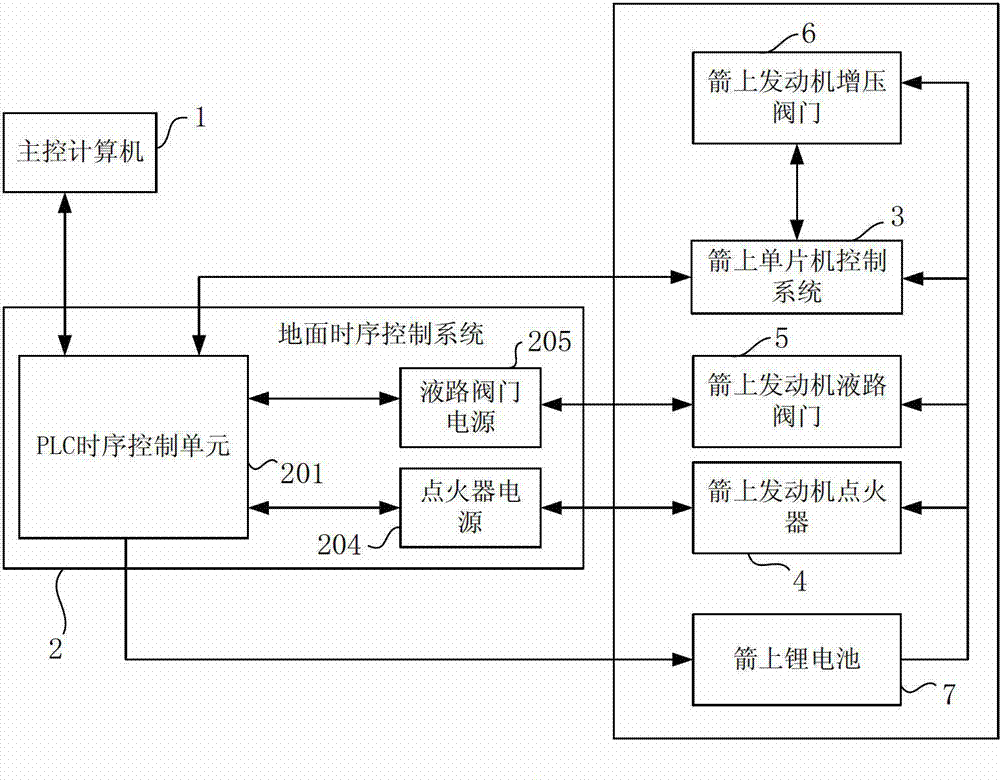

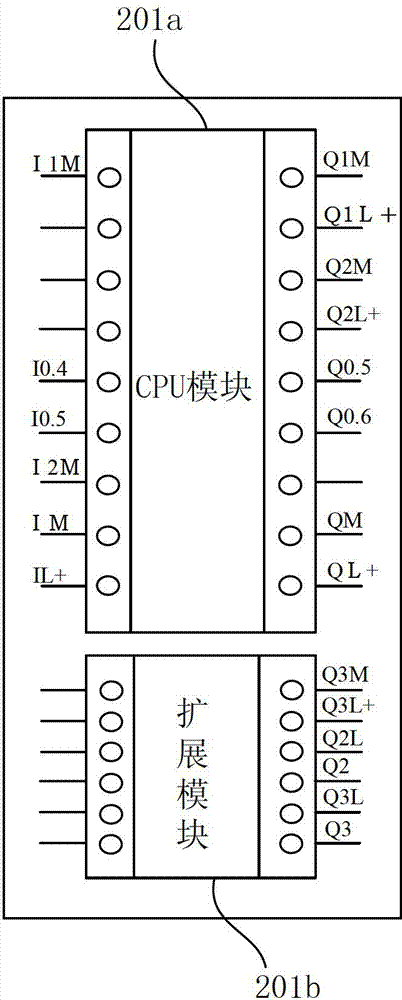

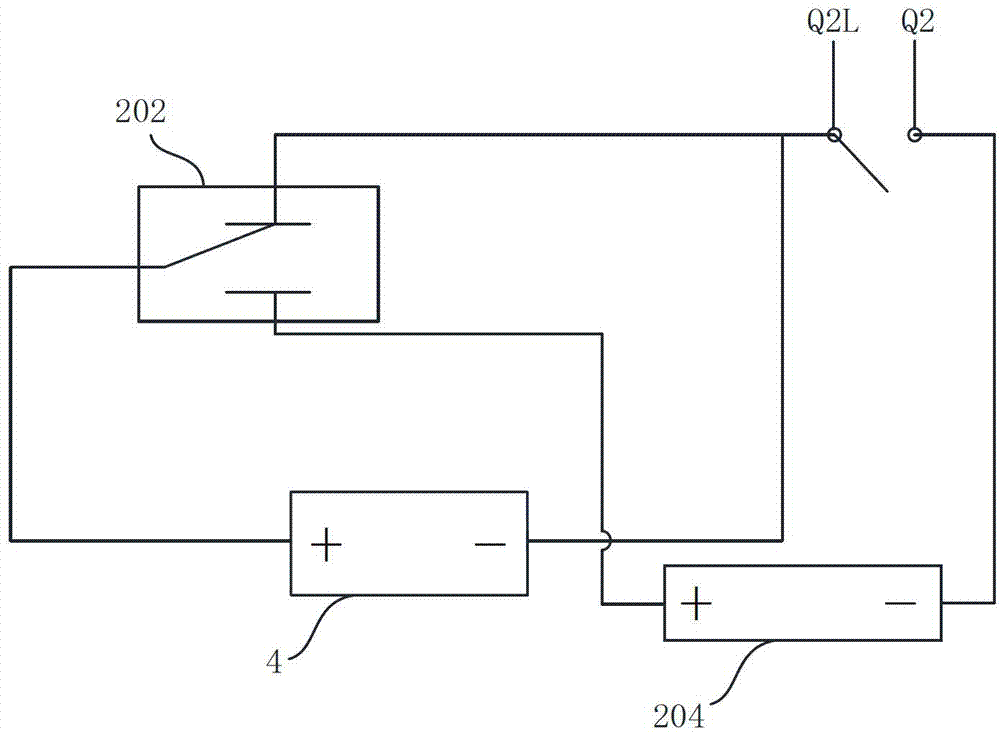

[0034] The present invention proposes a ground launch timing control system for solid-liquid powered sounding rockets, such as figure 1As shown, it includes a main control computer 1 , a ground sequence control system 2 and an arrow-on-single-chip microcomputer control system 3 . Among them, the main control computer 1 is used to send switch signals to the ground timing control system 2, through the ground timing control system 2 to control the opening and closing of the rocket engine igniter 4; the ground timing control system 2 is also used to control the rocket engine hydraulic valve 5 and the Arrow single-chip microcomputer control system 3 to control, and at the same time obtain the switch state information of the Arrow engine igniter 4 and the Arrow engine hydraulic valve 5, and send it to the main control computer 1. The single-chip microcomputer control system 3 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com