Dirt precipitator for a highly viscous medium

A separator and high-viscosity technology, which is applied in the field of dirt separators, can solve problems affecting the quality of molten materials and achieve the effect of increasing the filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

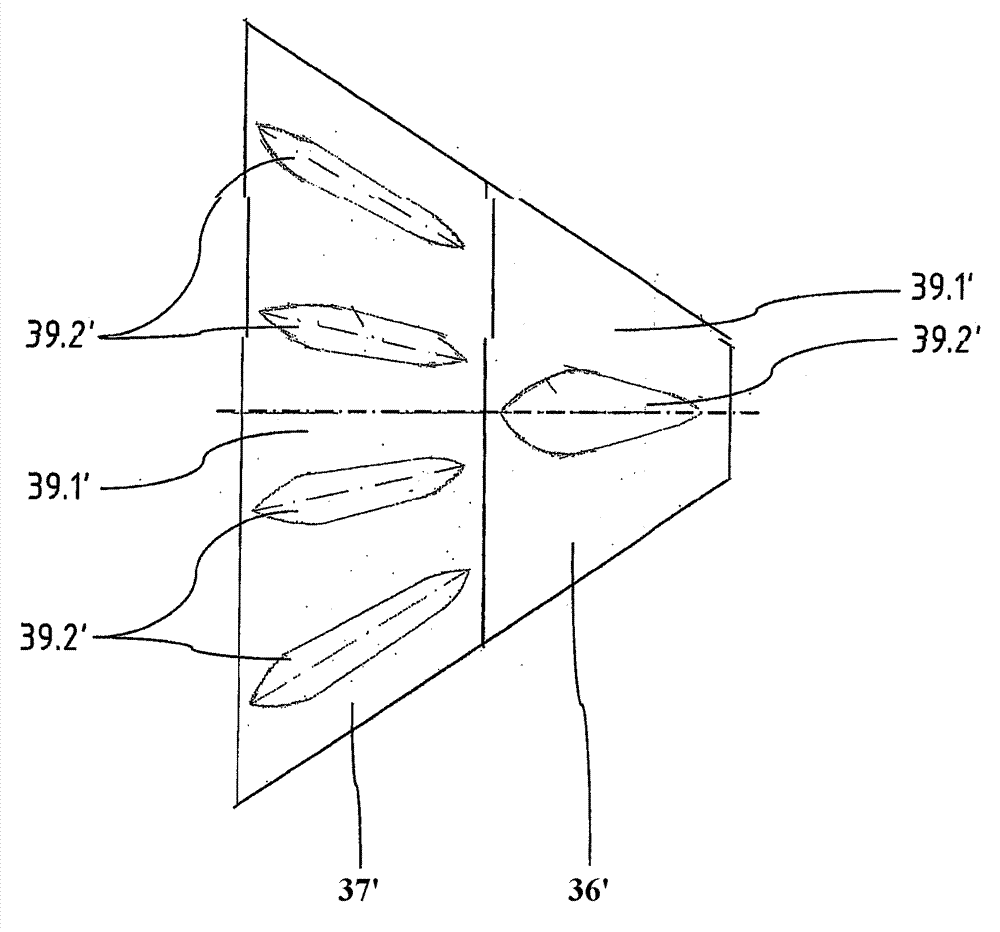

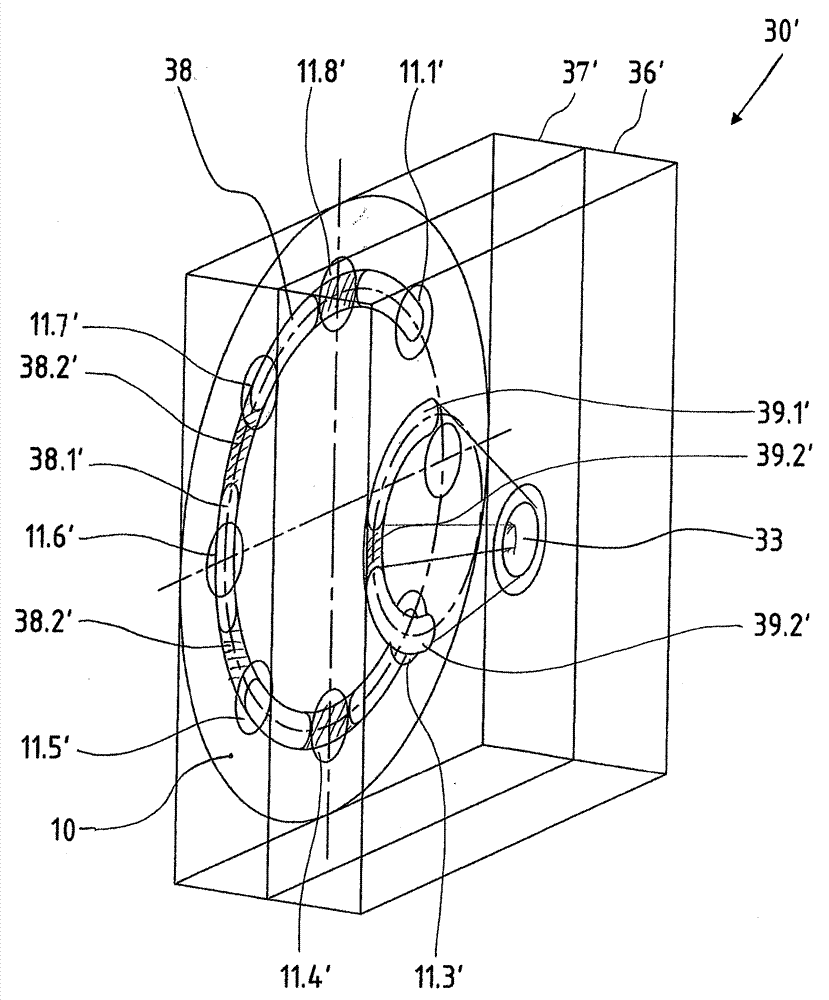

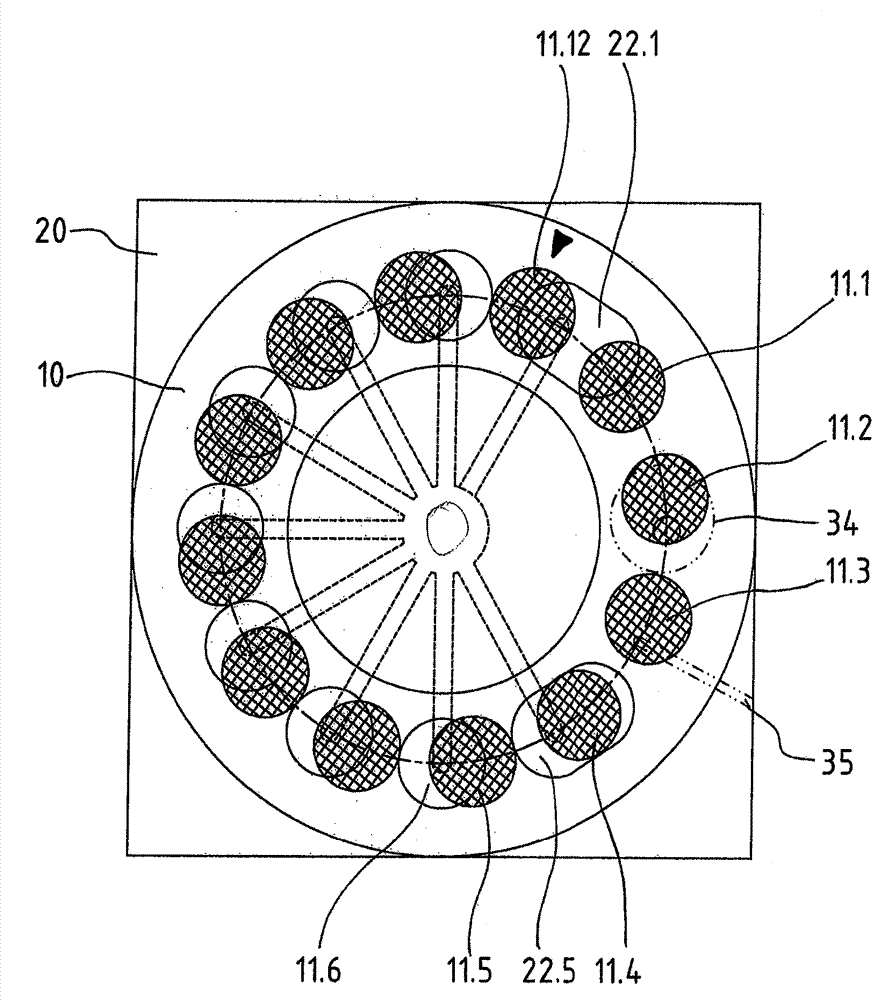

[0063] figure 1 Viewed on the housing from the front (viewed in the flow direction), the complete dirt separator 100 is shown, comprising the front housing element 30 and the rear housing element 20 . The housing elements 20 , 30 are arranged at a distance from one another and enclose between them a rotatable sieve wheel 10 with a plurality of sieve locations 11 . 1 . . . 11 . 12 .

[0064] Mounted at the housing is a drive unit 40 , which in this case comprises a pneumatic cylinder, which is supported in a pivotable manner and which has a follower element 41 at its end, which engages at the outer periphery of the sieve wheel 10 In the tooth portion 42 formed. Due to the own weight of the drive unit 40 , the follower element 41 always rests on the toothing 42 . With a slight advance movement, it rests on the tooth flank of the next tooth and sinks behind it, so that the sieve wheel 10 is rotated by an angle when viewed in the clockwise direction during the next pull-back mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com