Four-head counter rotating star lapping machine

A planetary grinding and mechanical technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of not being suitable for stone materials, the development of floor care, increasing labor intensity, and low mechanical efficiency of a single disc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, further illustrate how the present invention is realized:

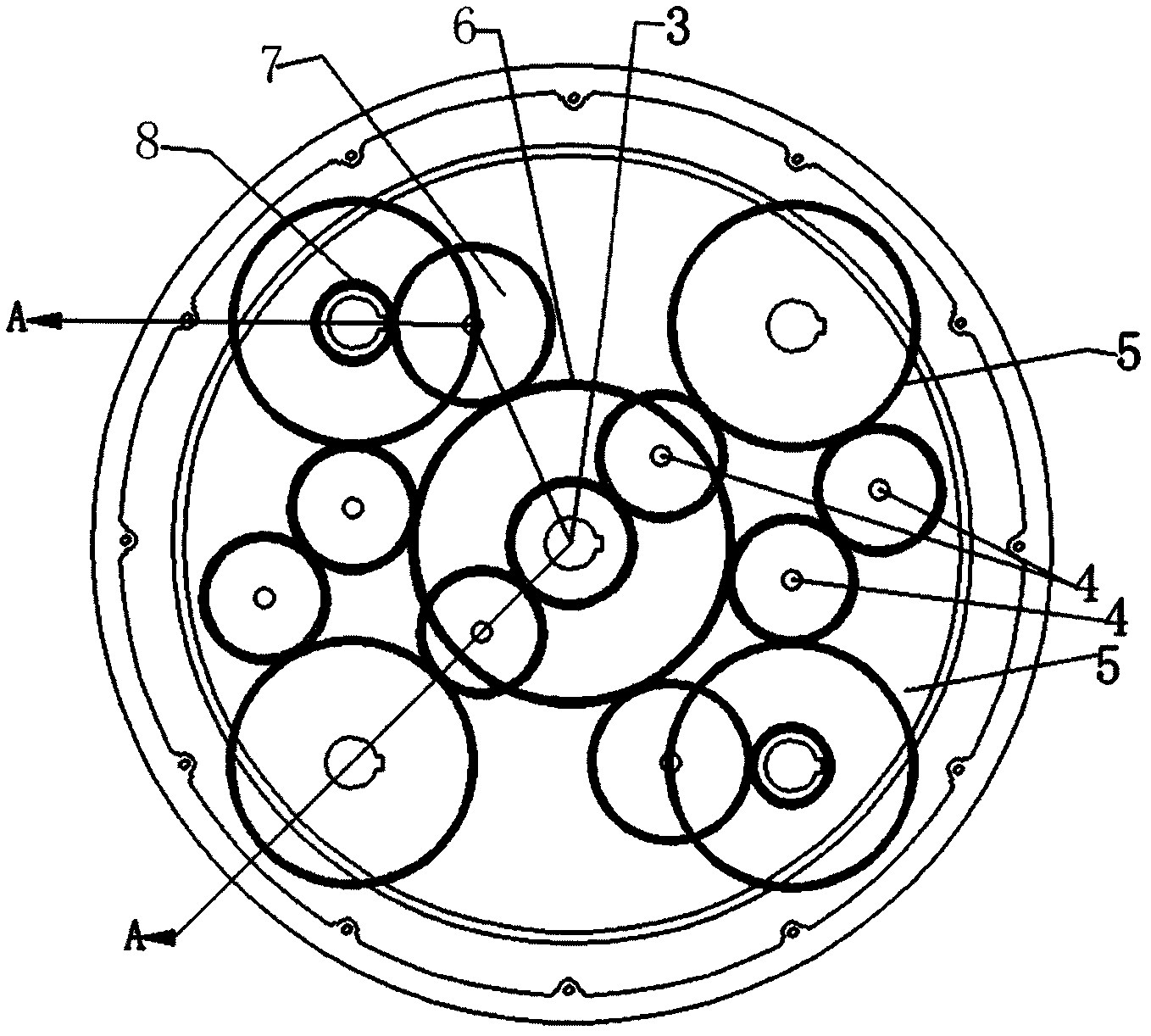

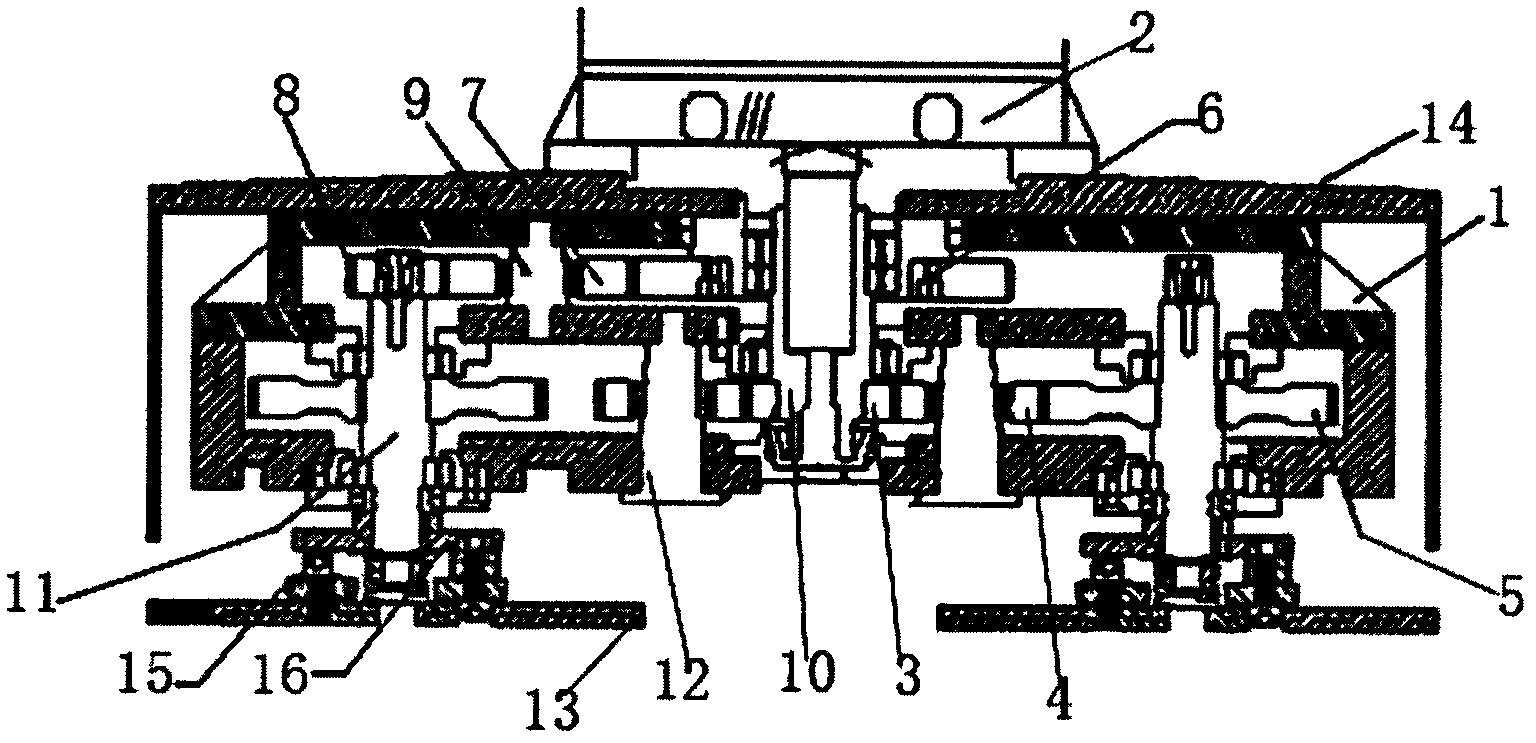

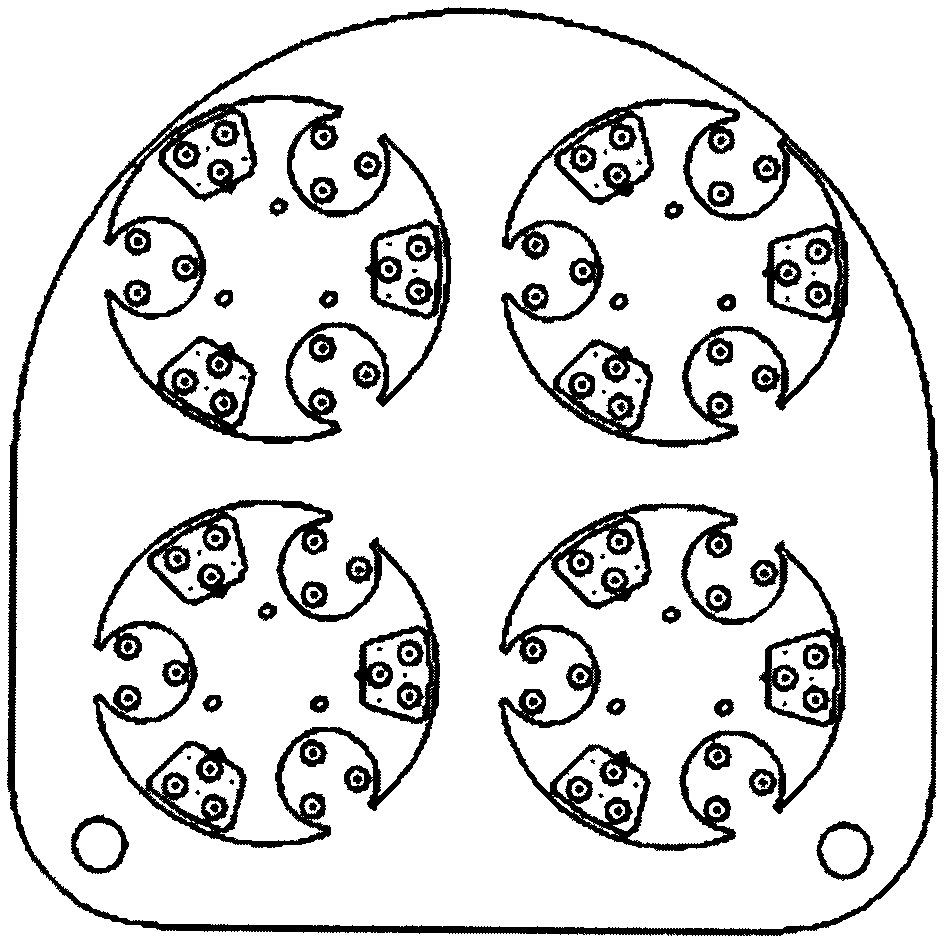

[0017] as attached figure 1 , 2 , 3, the four-head counter-rotating planetary grinding machine is composed of a main drive motor 2, a transmission double-layer gear box 1, and a grinding head cover 14. The motor 2 is fixedly connected to the grinding head cover 14, and the motor shaft and the main drive shaft 10 fits. Bottom box: the main transmission gear 3 is fixed on the main transmission shaft 10; the main transmission shaft 10 drives the main transmission gear 3, and the main transmission gear 3 is connected to the transition gear 4 and the transition gear shaft 12; the transmission gear 5 and the transmission shaft 11 are connected to each other Occlusion makes the grinding disc 13 form two positive and two opposite rotations, and the grinding disc forms self-rotation. Upper box body: two planetary gears 8 are installed on the transmission shaft 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com