Pushing machine with automatic concrete stirring device

An automatic mixing and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control device, etc., can solve the problems of inconvenient, high use cost, waste of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

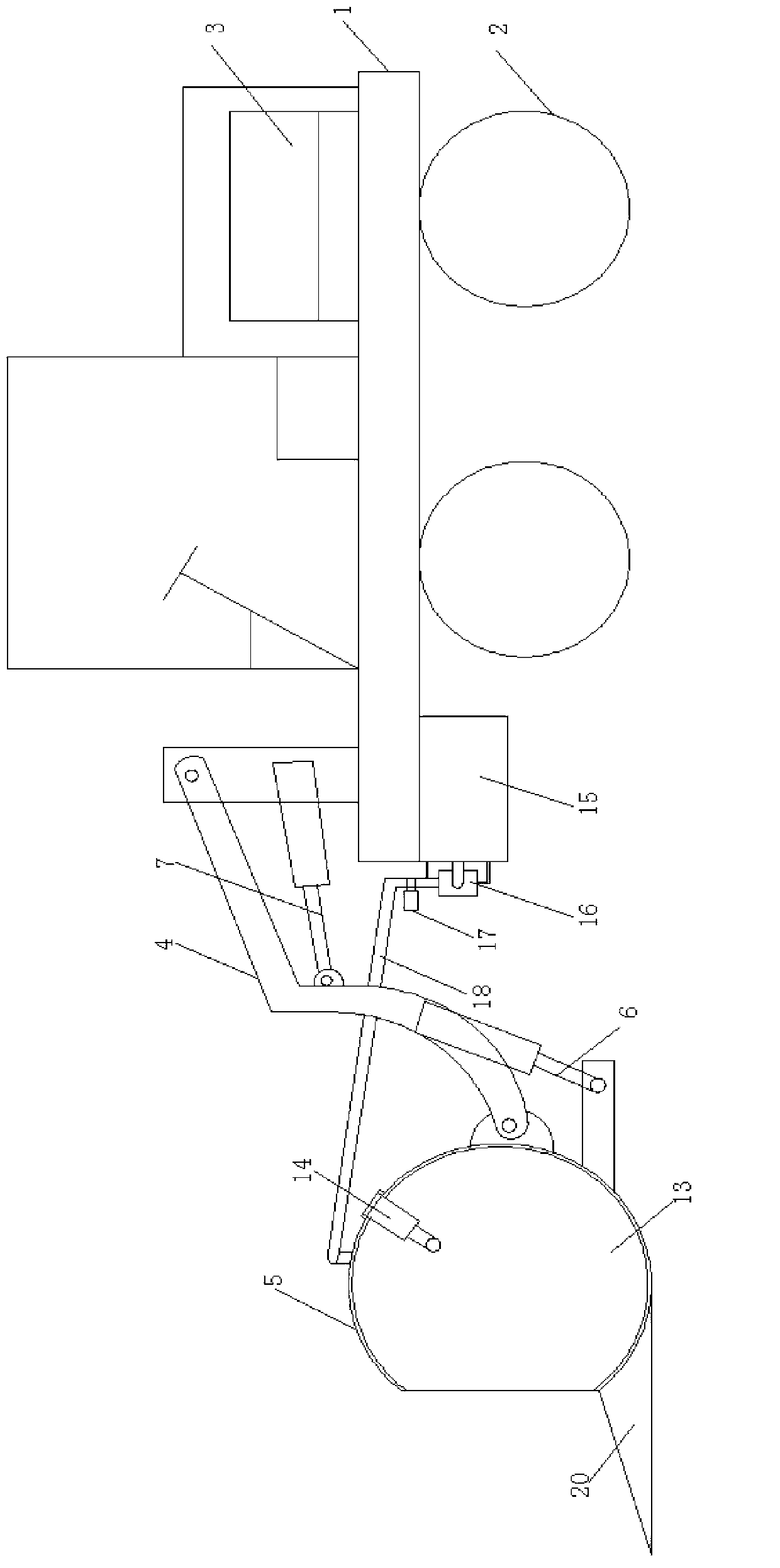

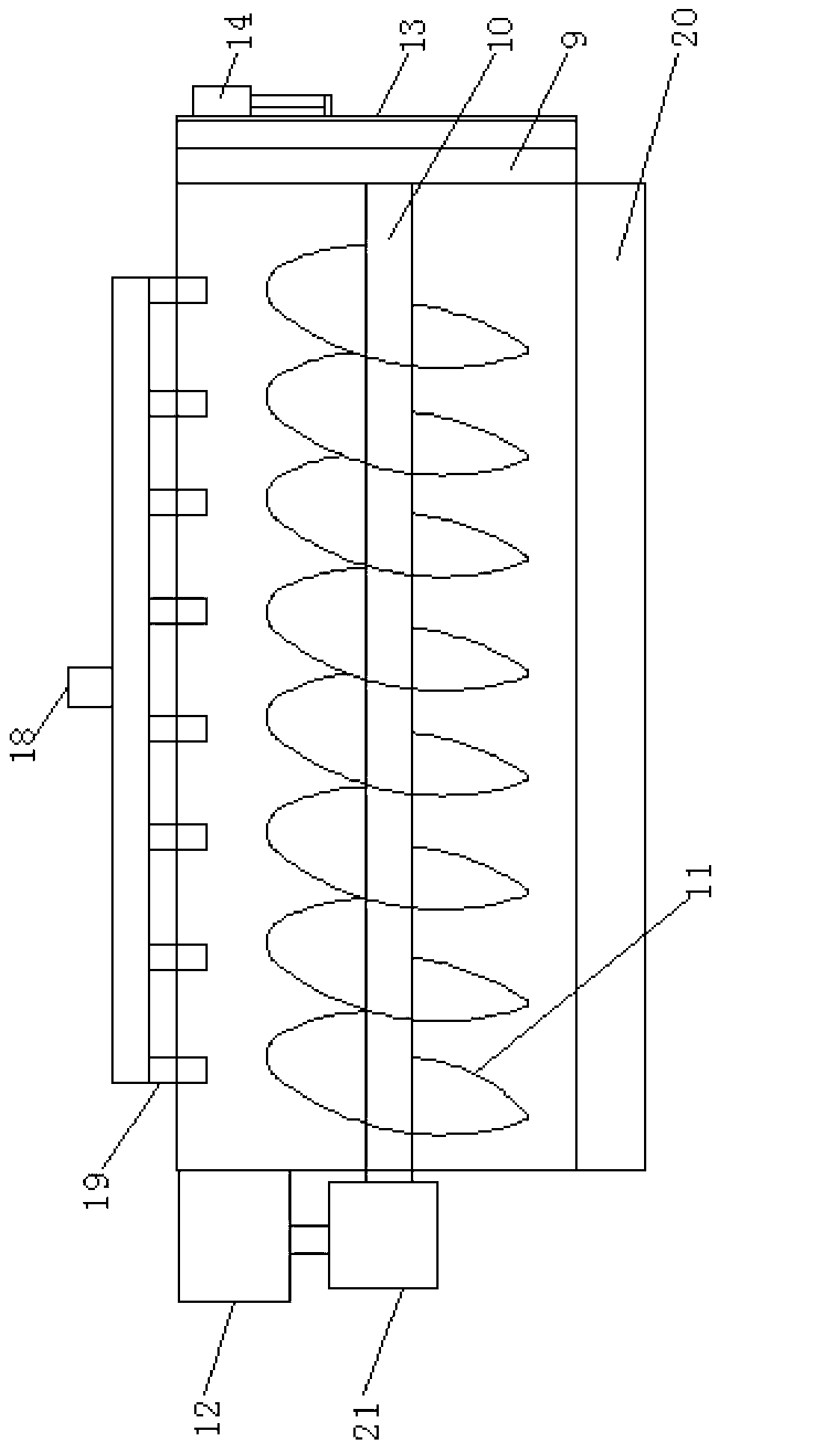

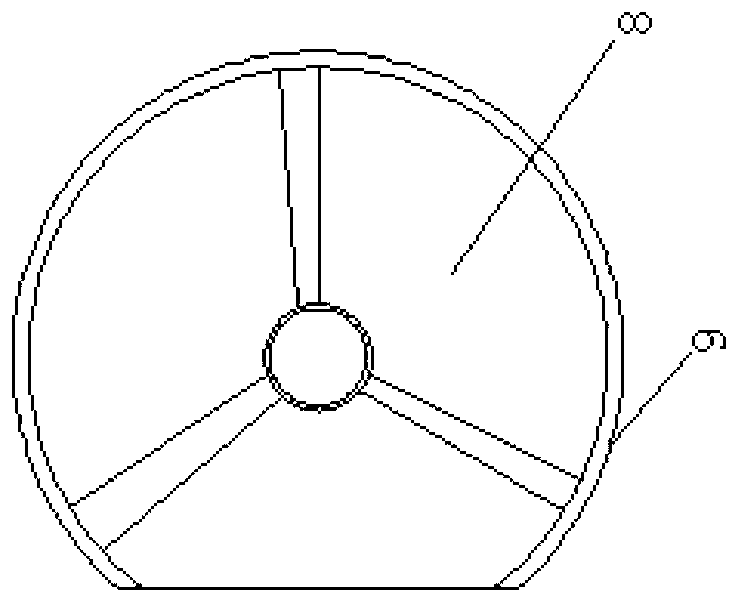

[0017] Such as figure 1 , 2 As shown in , 3, the pusher with automatic concrete mixing device includes a frame 1, a traveling wheel 2 arranged below the frame 1 and a driving device arranged on the frame 1 to drive the traveling wheel 2 to walk, and the driving device includes a The drive motor 3 and the transmission mechanism on the frame, the front end of the frame 1 is movably connected with a connecting push rod 4, and the front end of the connecting push rod 4 is movably connected with a pushing shovel 5, and the pushing shovel 5 and the connecting push rod 4 are arranged There is a first hydraulic mechanism 6, and a second hydraulic mechanism 7 is arranged between the middle part of the push rod 4 and the front end of the frame 1. One side of the pushing shovel 5 is an open end, and the other side is a closed end, and the open end is int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap