Drum type washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of weight increase, upper reinforcement plate width limitation, etc., and achieve the effect of improving strength and realizing light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, modes for implementing the present invention (hereinafter referred to as “embodiments”) will be described in detail with reference to the drawings as appropriate.

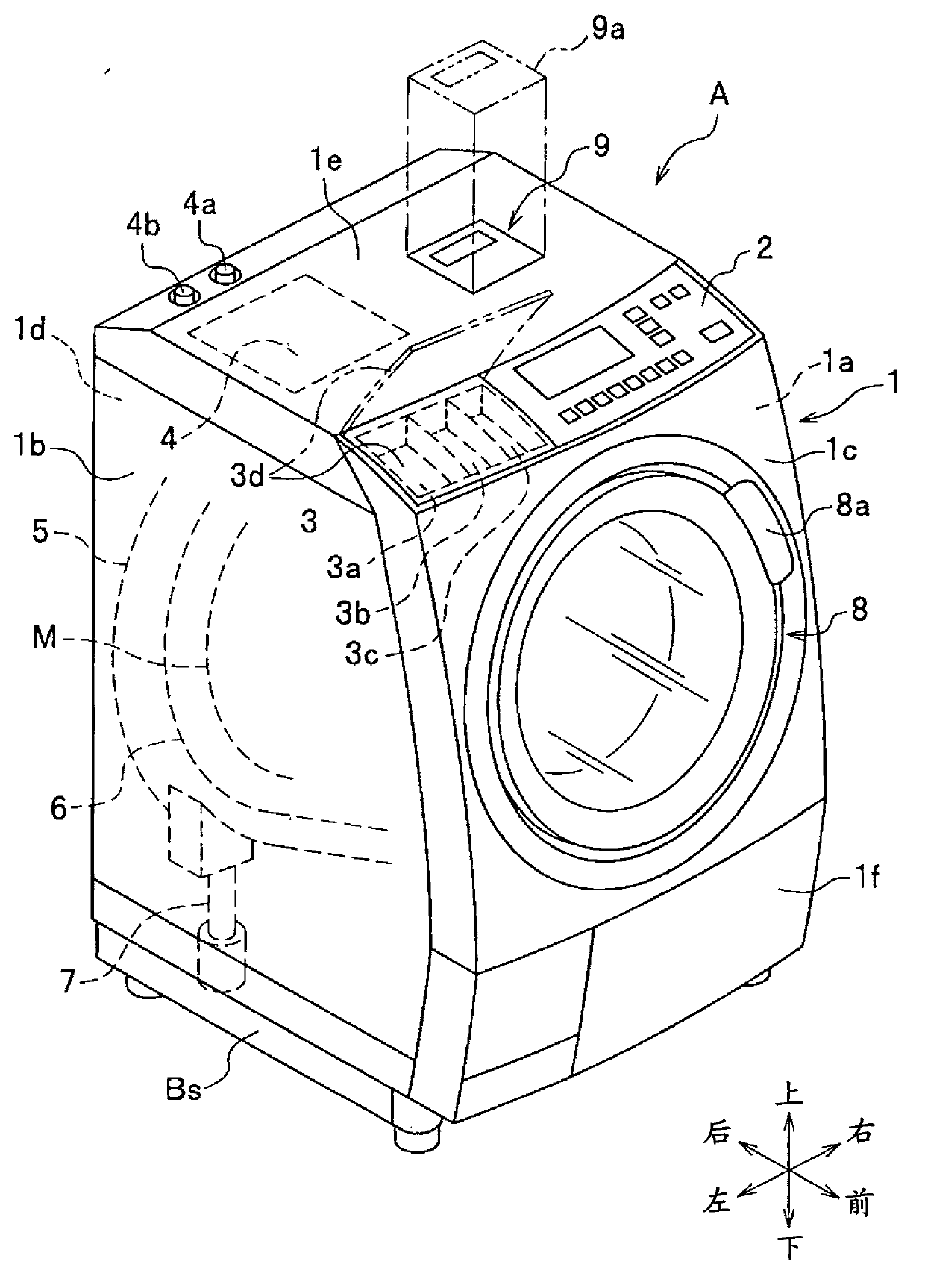

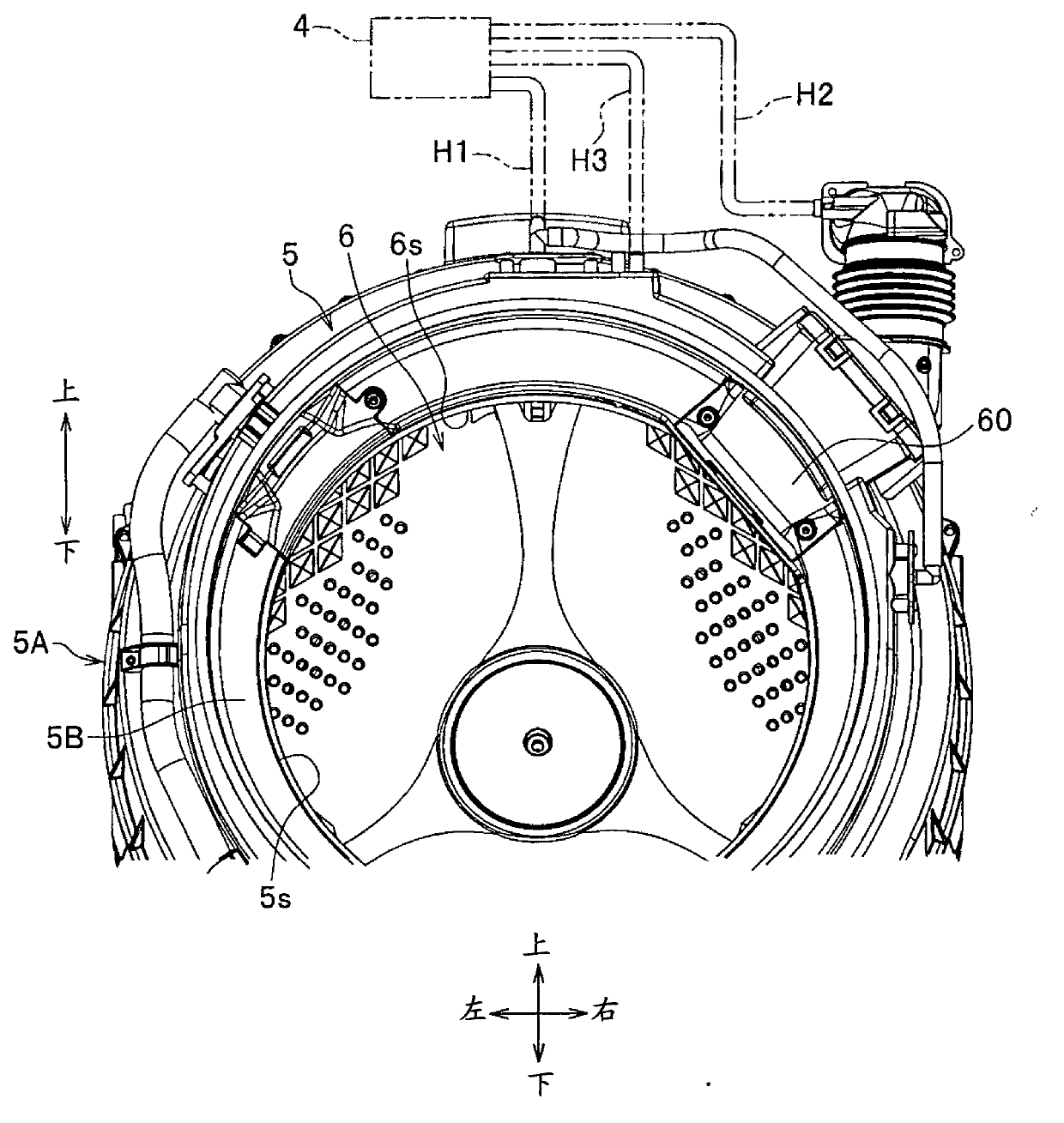

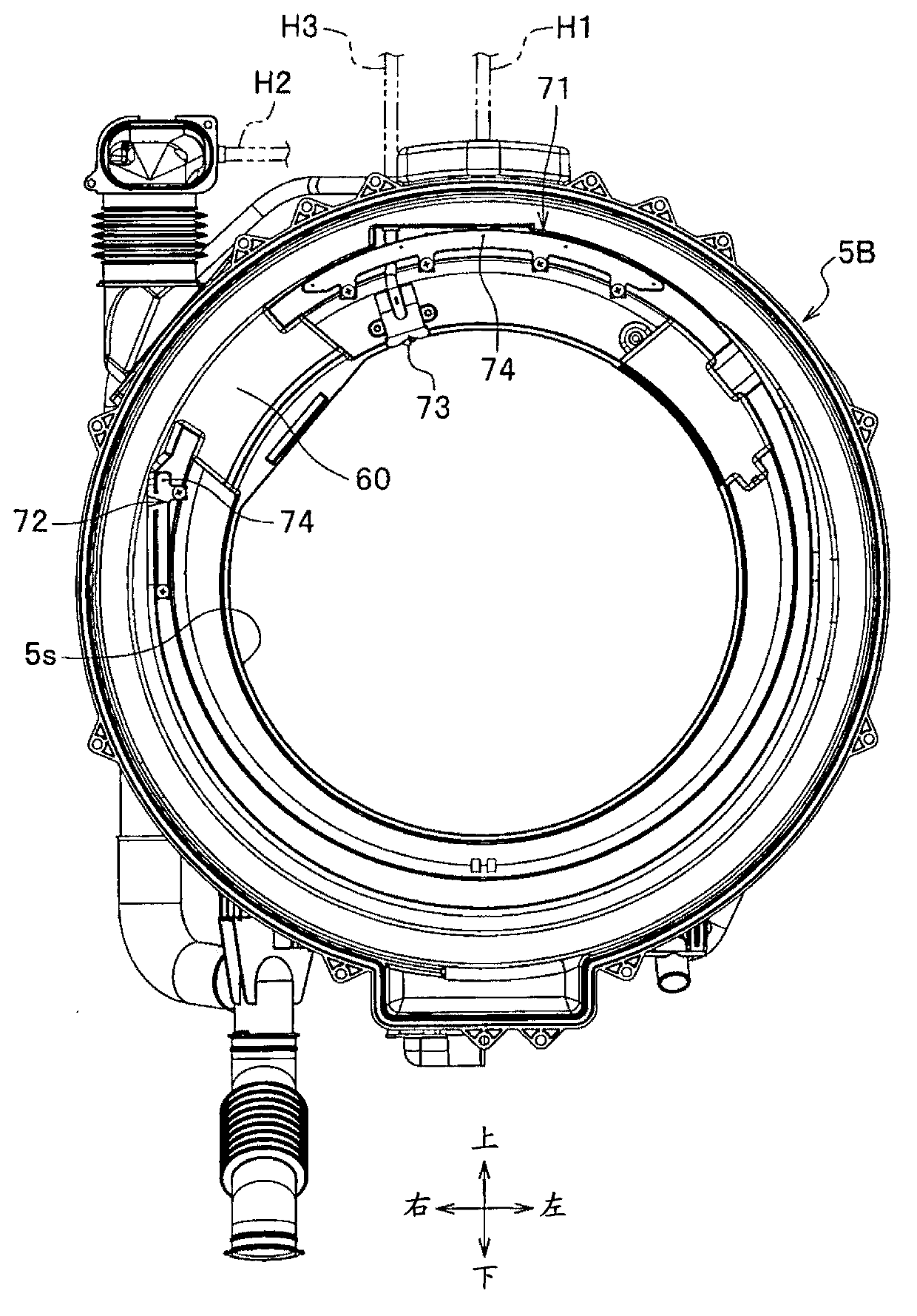

[0022] like figure 1 As shown, the front-loading washing machine A (hereinafter referred to as "washing machine") of this embodiment is capable of performing the steps from washing to drying, and has a housing 1 whose outer contour is composed of a steel plate and a resin molded product. of. The box 1 is provided with an operation panel 2, a detergent box 3, a water supply unit 4, an outer tank 5, a rotating drum (inner tank) 6, a shock absorber 7, a door 8, a dry filter 9, a motor M, and the like.

[0023] The box body 1 consists of a base Bs, a right side plate 1a (refer to Figure 4 ), left side panel 1b (right side panel 1a and left side panel 1b are combined to form left and right side panels), front cover 1c, back cover 1d, upper cover 1e and lower front cover 1f. The right side plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com