Net portion grooming roller cleaning device

The technology of a net part and a water spray pipe is applied in the field of the device field of cleaning the finishing roller of the net part, which can solve the problems of material stop and dismantling, irregular operation, and large area of slurries on the roll surface, so as to improve the papermaking rate and the finished product rate. , Improve the cleaning effect, improve the effect of filtering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

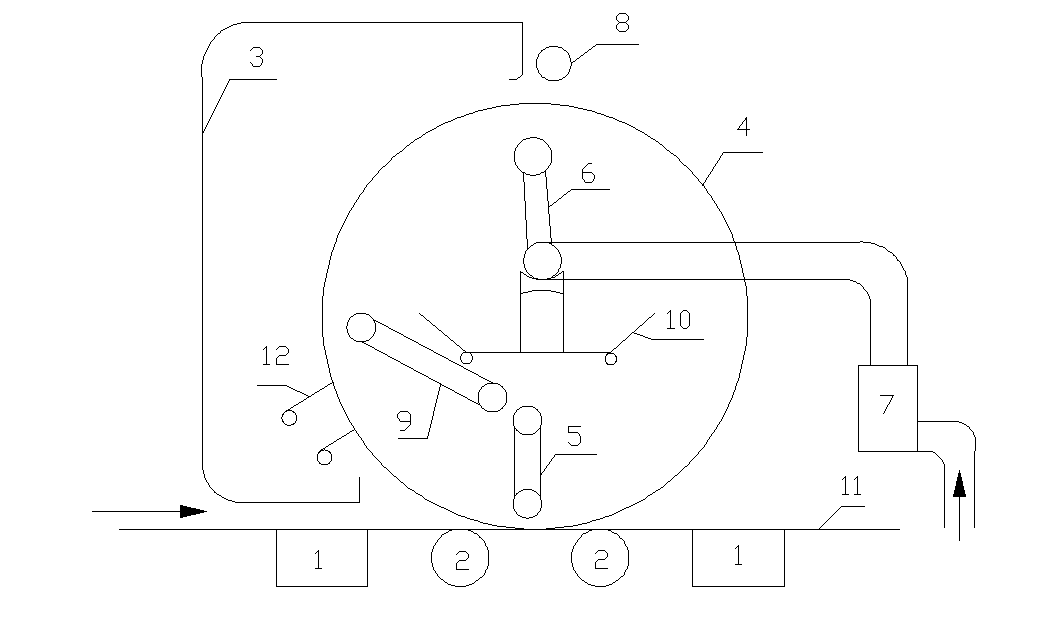

[0017] The device of the present invention for cleaning the finishing roller of the wire part is an improvement on the original device for cleaning the finishing roller of the wire part. The table roller 2 and the suction box 1 for dehydrating and supporting the net surface are installed below the net 11. The outer side of the finishing roller 4 is provided with an air cover 3 in a half-wrapped state. A scraper 12 is installed on the side of the finishing roller 4 . A water spray pipe 6 and a steam pipe 5 are installed inside the finishing roller 4 for cleaning the finishing roller. A water receiving tray 10 is installed below the spray pipe 6 . The improvement of the present invention is that a filter 7 is installed on the water inlet pipe of the water spray pipe 6 to reduce the probability of nozzle clogging. Install a movable water spray pipe 8 on the outside of the finishing roller 4, and cooperate with the inside water spray pipe 6 (nozzle diameter 0.05mm, spacing 5cm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com