Reinforced concrete pipe for structure of rotatablely excavated pile shell

A technology of reinforced concrete pipes and rotary piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as difficulty, installation and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

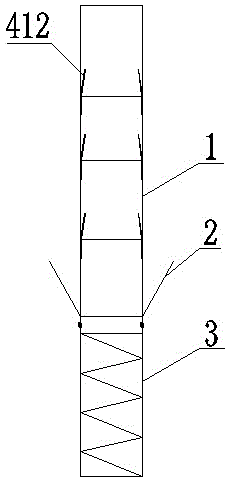

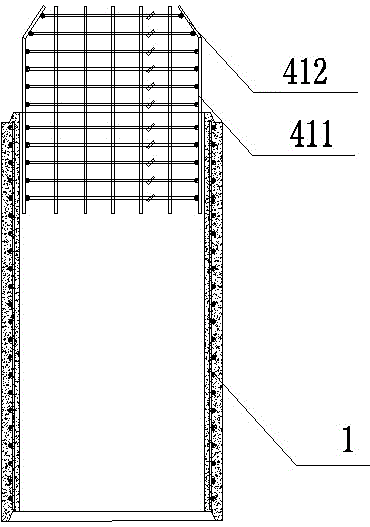

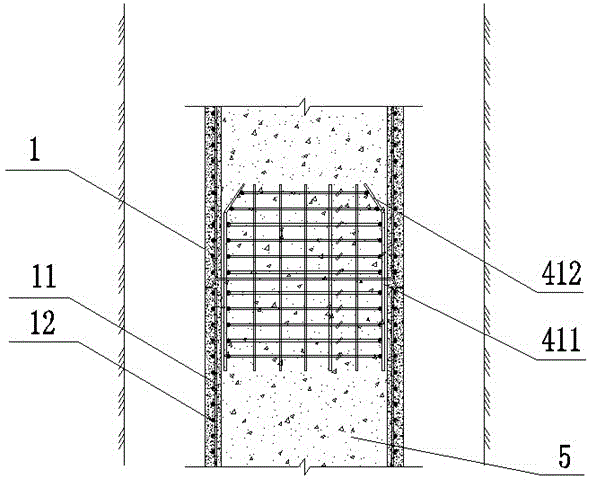

[0022] Embodiment 1: (see figure 2 - image 3 ), a reinforced concrete pipe used for the pile shell structure of rotary excavation piles, including a pipe body 1, the pipe body 1 contains a number of longitudinal bars 11 and a number of stirrup bars 12, and the connecting parts of the two ends or one end of the pipe body 1 A reinforcement connection structure is provided for positioning and connecting two adjacent pipe bodies into an integrated structure. The connecting structure of the steel bar is a socketing method; one end of the pipe body 1 is provided with a convex ring section 411, and the other end of the pipe body 1 is provided with a socket section matched with the convex ring section 411; the convex ring section 411 consists of several vertically arranged main reinforcements and circumferentially arranged stirrups.

[0023] In order to improve the docking operability and facilitate the guided docking, the upper end of the convex ring section 411 is also provided ...

Embodiment 2

[0027] Embodiment 2: (see Figure 4 - Image 6 ), and the difference from Embodiment 1 is that the steel bar connection structure is a butt joint; screw sections 421 and 422 are respectively extended outward along the pipe wall at both ends of the pipe body 1 , and are butt jointed by a sleeve 423 .

[0028] In this embodiment, when two adjacent pipe bodies need to be fastened, the one-to-one corresponding upper and lower extension sections are aligned with each other, and then the sleeves pre-fixed on the upper / lower extension sections are screwed in the opposite direction, and the one-to-one correspondence The connection (gap) of the upper and lower extension sections is located in the sleeve, which realizes the one-to-one fixed connection of the upper and lower extension sections.

[0029] In order to prevent concrete from leaking at the joint between the pipes during the pouring process, a ring plate 62 can be arranged on the outer circumference of the joint of the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com