Refrigeration cycle apparatus and hot water producing apparatus

A technology of circulation device and decompression device, used in refrigeration and liquefaction, lighting and heating equipment, refrigerators, etc., can solve the problems of complicated refrigeration cycle and increased cost of parts, shortening defrosting time, improving operation efficiency, The effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

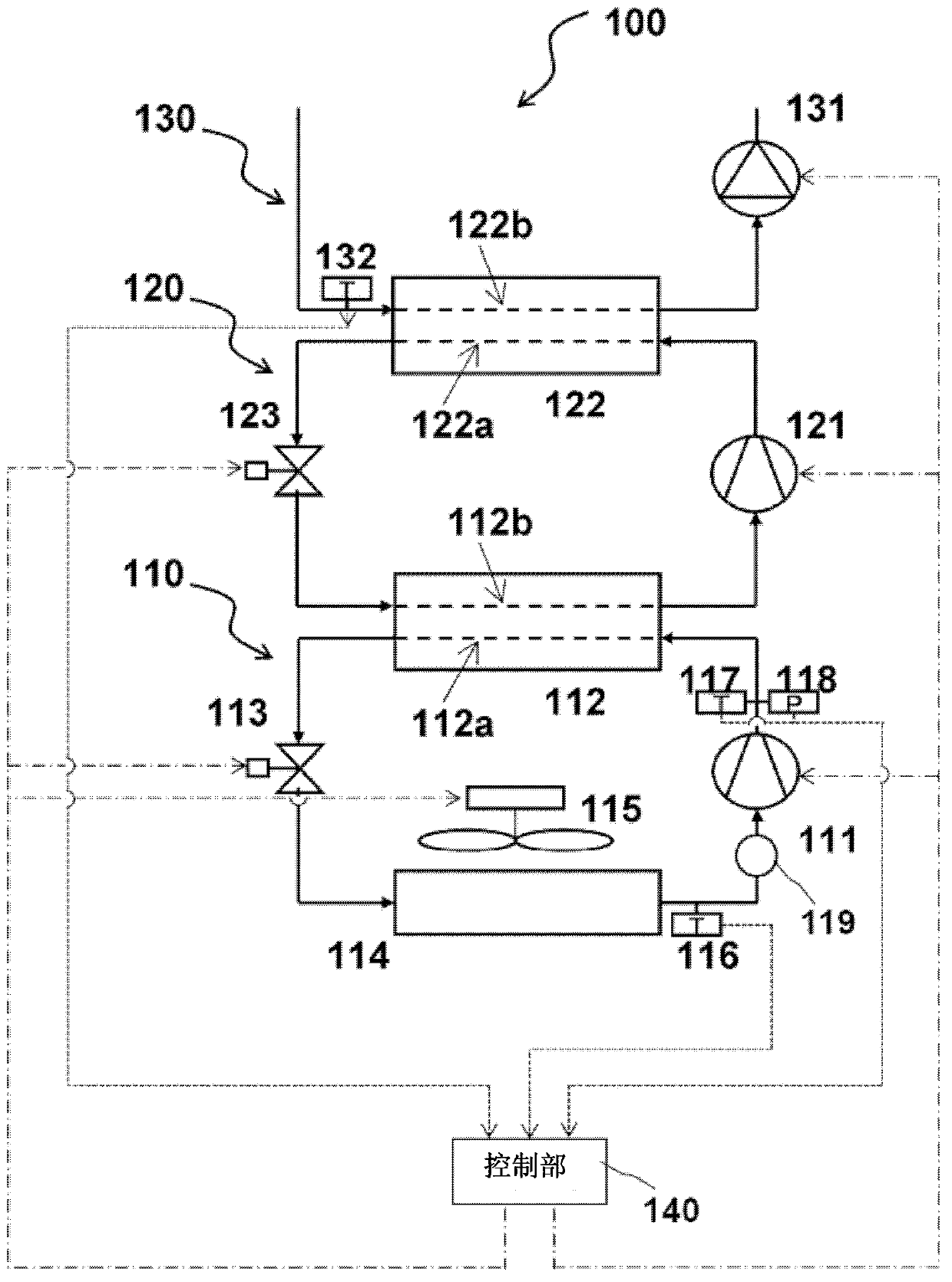

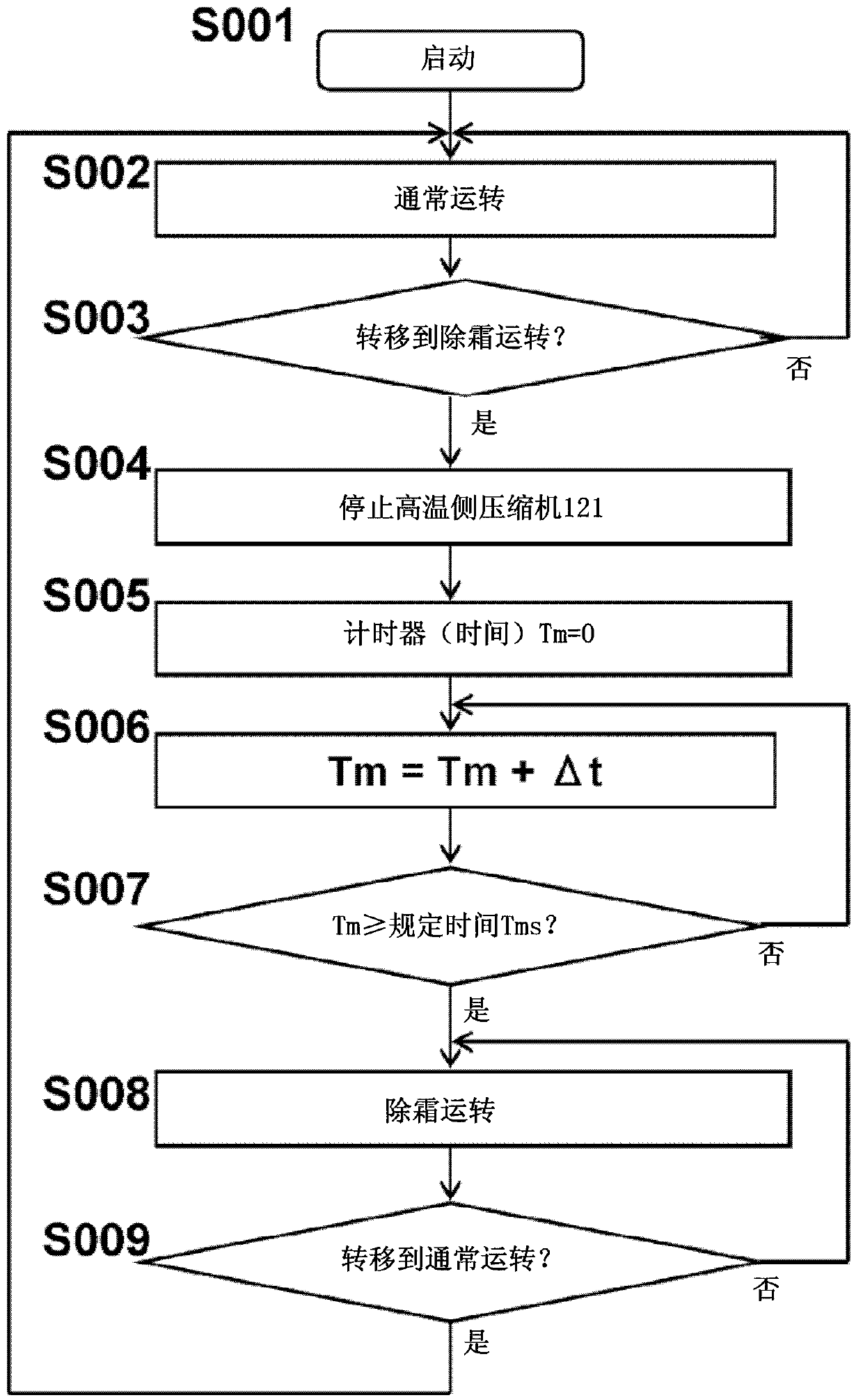

[0078] figure 1 It is a configuration diagram of a binary refrigeration cycle apparatus according to Embodiment 1 of the present invention. The binary refrigeration cycle device 100 is composed of a low temperature side refrigeration cycle 110 , a high temperature side refrigeration cycle 120 , a heat medium cycle 130 , and a control unit 140 .

[0079] The low-temperature side refrigeration cycle 110 is a cascade heat exchange in which the low-temperature side compressor 111 that sucks in the low-temperature side refrigerant in a gaseous state and compresses it, and discharges high-temperature and high-pressure low-temperature side refrigerant, and the low-temperature side refrigerant and the high-temperature side refrigerant perform heat exchange. The device 112, the low-temperature side decompression device 113 for adjusting the flow rate of the low-temperature side refrigerant, and the air heat exchanger (low-temperature side evaporator) 114 for taking heat from the outdo...

Embodiment approach 2

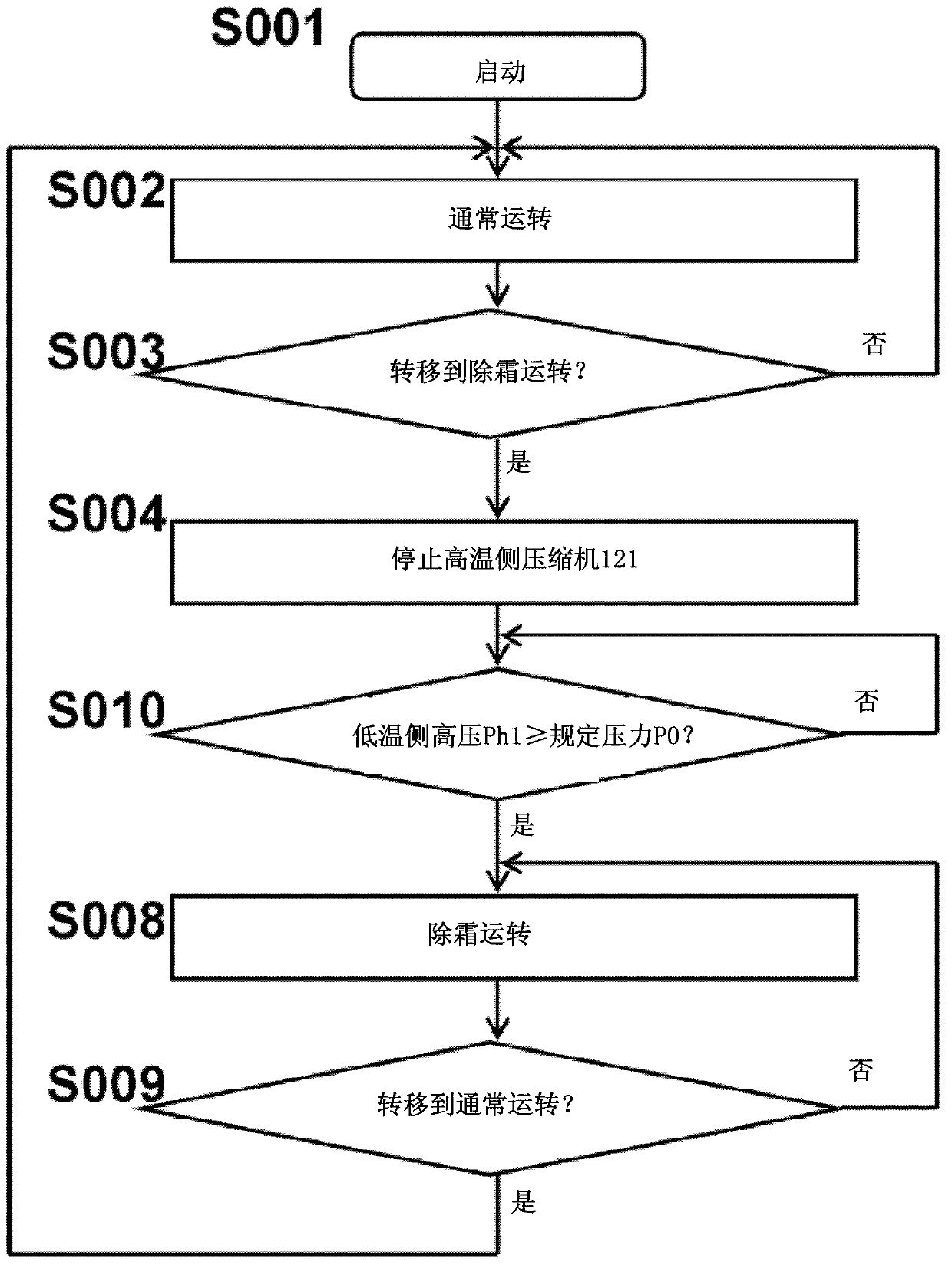

[0113] image 3 It is a flowchart explaining the control operation of the control unit in the second embodiment of the present invention.

[0114] In addition, in this embodiment, the configuration of the binary refrigeration cycle apparatus 100 is the same as figure 1 Since they are the same, descriptions of these constituent elements are omitted.

[0115] image 3 compared to figure 2 , because there are no steps 005 to 007, the process of step 010 is added instead. Other processing and figure 2 The same, so in this embodiment, the operation of step 010 will be mainly described.

[0116] When it is determined in step 003 that the control unit 140 has shifted to the defrosting operation, it stops the high temperature side compressor 121 in the next step 004 . Then, as in the first embodiment, the temperature of the low-temperature side refrigerant flowing through the flow passage 112a in the cascade heat exchanger 112 rises rapidly, and heat is stored from the low-te...

Embodiment approach 3

[0124] Figure 4 It is a flowchart illustrating the control operation of the control unit according to the third embodiment of the present invention.

[0125] In addition, in this embodiment, the configuration of the binary refrigeration cycle apparatus 100 is the same as figure 1 Since they are the same, descriptions of their constituent elements are omitted.

[0126] Figure 4 compared to image 3 (Second embodiment), instead of step 101, the flow of step 011 is added. Other processing and image 3 The same, so in this embodiment, the operation of step 011 will be mainly described.

[0127] When it is determined in step 003 that the control unit 140 has shifted to the defrosting operation, it stops the high temperature side compressor 121 in the next step 004 . Then, as in the first embodiment, the temperature of the low-temperature side refrigerant flowing through the flow passage 112a in the cascade heat exchanger 112 rises rapidly, and heat is stored from the low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com