Radial and Circumferential Deformation Measurement Method and System of High Temperature and High Pressure Working Cylinder

A high-temperature, high-pressure, radial deformation technology is applied to measuring devices, instruments, and optical devices to improve design quality and ensure safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings.

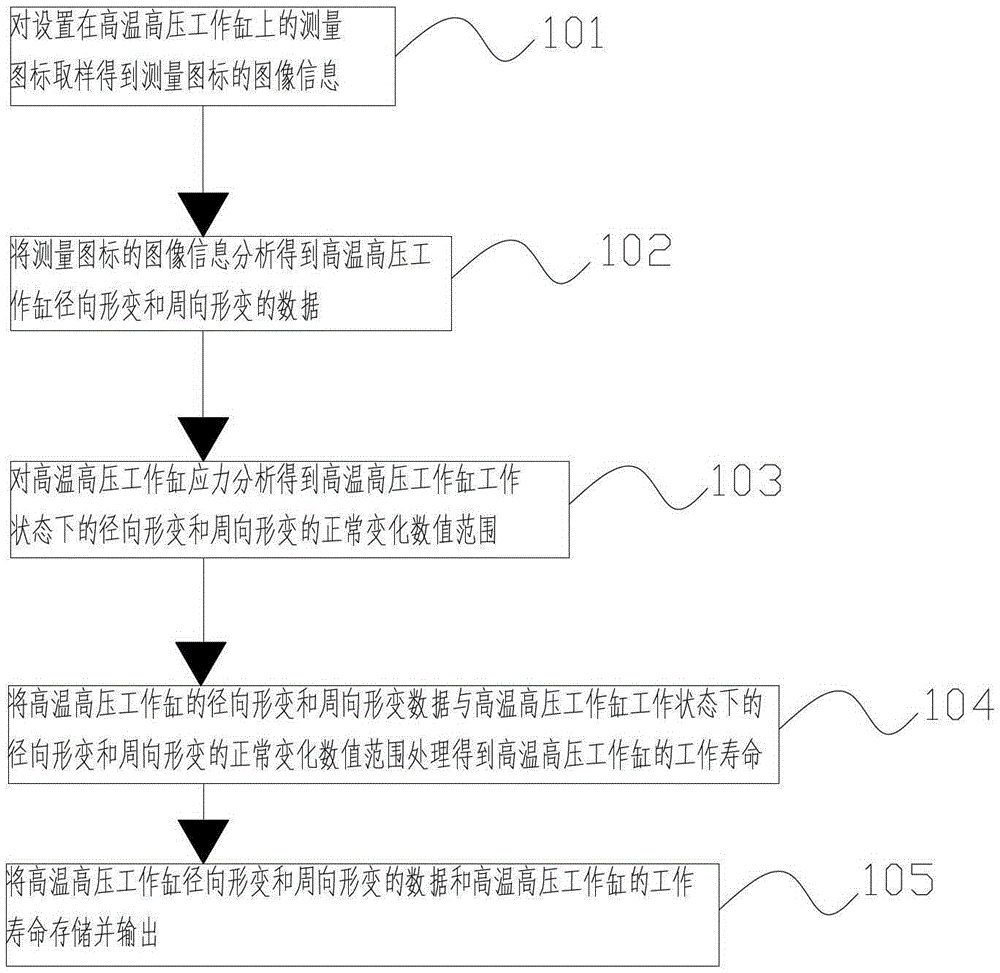

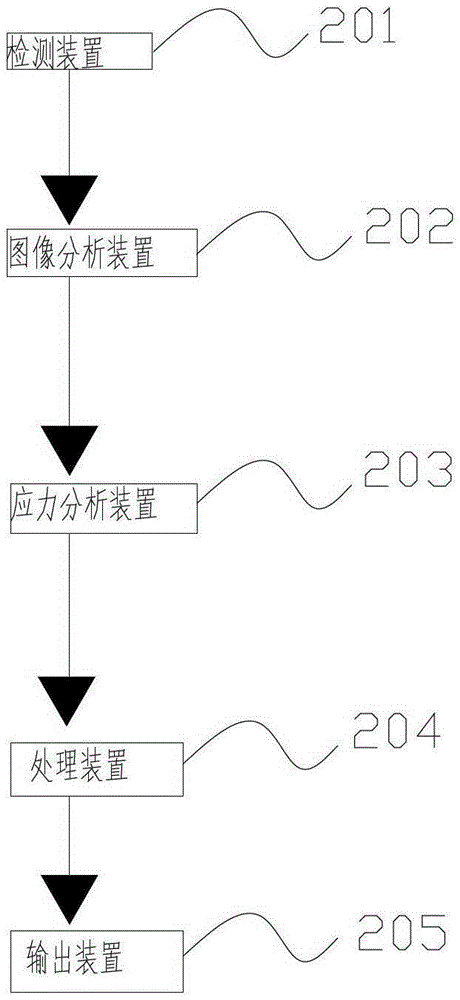

[0031] Such as figure 1 The radial and circumferential deformation measurement method and systematic method of a high-temperature and high-pressure working cylinder include:

[0032] Sampling the measurement icon set on the high temperature and high pressure working cylinder to obtain the image information 101 of the change of the measurement icon;

[0033] Perform image analysis on the image information of the measurement icon to obtain data 102 of radial deformation and circumferential deformation of the high temperature and high pressure working cylinder;

[0034] The stress analysis of the high-temperature and high-pressure working cylinder shows that the normal change value range of radial deformation and circumferential deformation of the high-temperature and high-pressure working cylinder is 103;

[0035] Processing the radial deformation and circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com