Three-level gas coupled pulse pipe refrigerator designing method based on circuit analogy and entropy analysis

A technology of pulse tube refrigerator and design method, which is applied in gas cycle refrigerator, refrigerator, refrigeration and liquefaction, etc., can solve the problems of large volume, no efficient design method, and difficult control of working fluid flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention is acceptable. Should be included in the protection scope of the present invention.

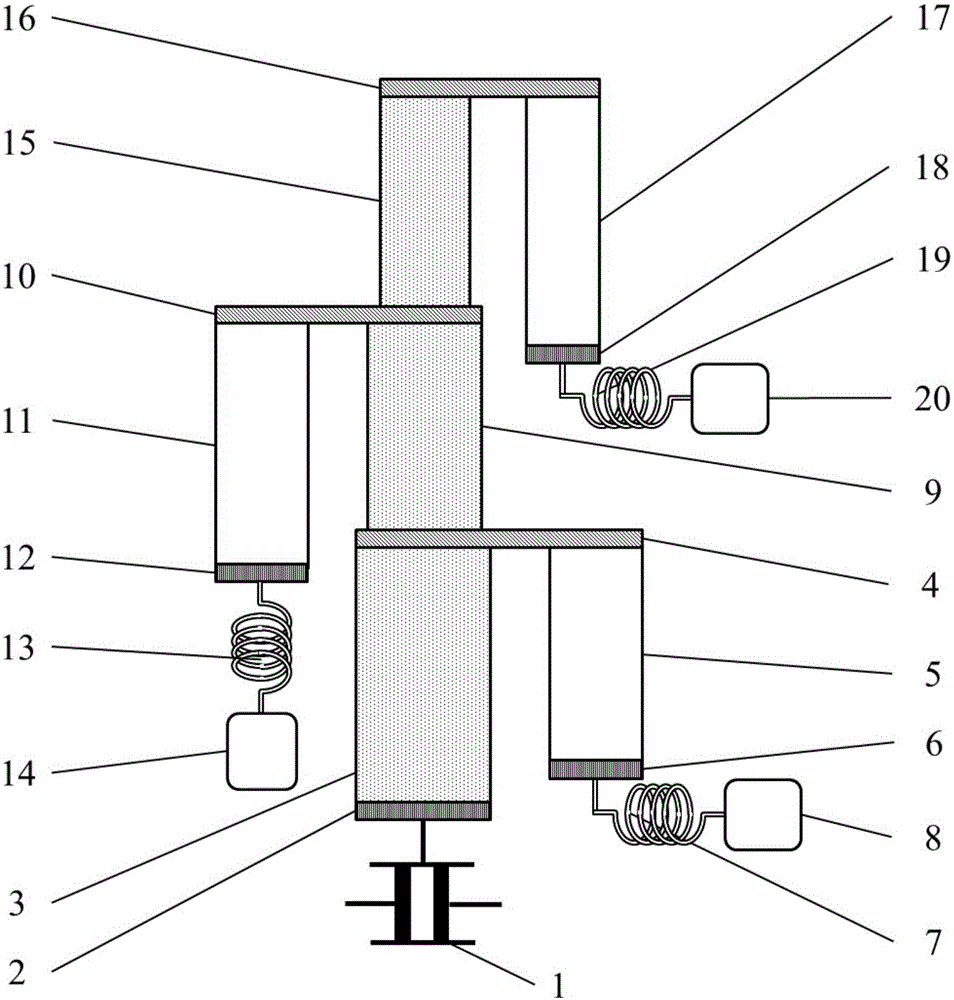

[0094] The system structure of this embodiment is as follows figure 1 As shown, it is assumed that the first-stage cold storage packing is #400 mesh wire mesh, the second-stage cold storage packing is lead balls, and the third-stage cold storage packing is Er 3 Ni particles. The design scheme then includes the following steps:

[0095] Step 1: Establish a three-stage gas-coupled pulse tube refrigerator structure model;

[0096] The model includes: compressor 1, aftercooler 2, first-stage regenerator 3, first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com