Pipeline full-size blasting cutting test device and test method

A technology of blasting cutting and testing device, applied in blasting, using stable tension/pressure to test the strength of materials, etc., can solve the problems of inability to guarantee, inability to produce long cracks, and inability to ensure the safety of operators, and to solve the problem of detonator safety. Influence, precise detonation system performance, and the effect of improving delay accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Piping full-scale blasting cutting test device

[0060] A pipeline full-scale blasting cutting test device, comprising: a linear shaped energy cutter, a plurality of ignition devices and an initiation network, the initiation network controls the explosion of the linear shaped energy cutter and the firing time of the ignition device.

[0061] Such as figure 1 As shown, the linear shaped energy cutter is installed at the 12 o'clock position on the top of the center of the crack initiation tube along the axial direction of the crack initiation tube; the penetrating crack introduced by the linear energy gathering cutter should be parallel to the axial direction of the crack initiation tube, and the width of the penetrating crack is 10mm, length 500mm.

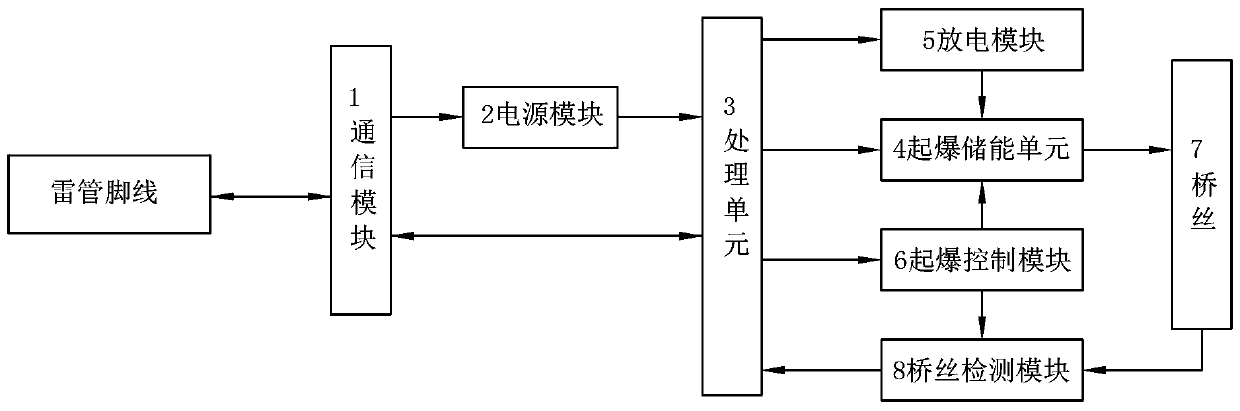

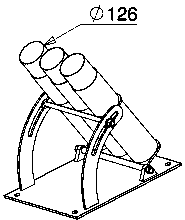

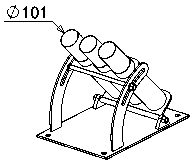

[0062] The linear energy-concentrating cutter includes two digital electronic detonators. Each digital electronic detonator is detonated in the middle of the explosion. Each digital electronic detonator is equipp...

Embodiment 2

[0073] Embodiment 2: Pipeline full-scale blasting cutting test method

[0074] 2.1 Requirements for blasting construction: use a linear shaped energy-concentrating cutter to cut a penetrating crack with a length of 500 mm and a width of 10 mm in the axial direction under the condition that an X80 pipeline with a diameter of 1422 mm and a thickness of 21.4 mm is filled with 13.3 MPa natural gas, and ignite it The device ignites cut gas that leaks into the air.

[0075] 2.2 Technical requirements for linear shaped energy cutter:

[0076] (1) Before the test, the steel pipe or steel plate of the same specification as the test should be used to conduct the cutting test of the linear energy-concentrating cutter to ensure reliable cutting;

[0077] (2) A linear shaped energy cutter should be installed before soil backfilling;

[0078] (3) The linear energy-concentrating cutter should be installed at the 12 o'clock position on the top of the center of the cracking tube along the ax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com