Igniting device

A technology of circuit devices and ignition pulses, applied in lighting devices, light sources, electrical components, etc., can solve problems such as high inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

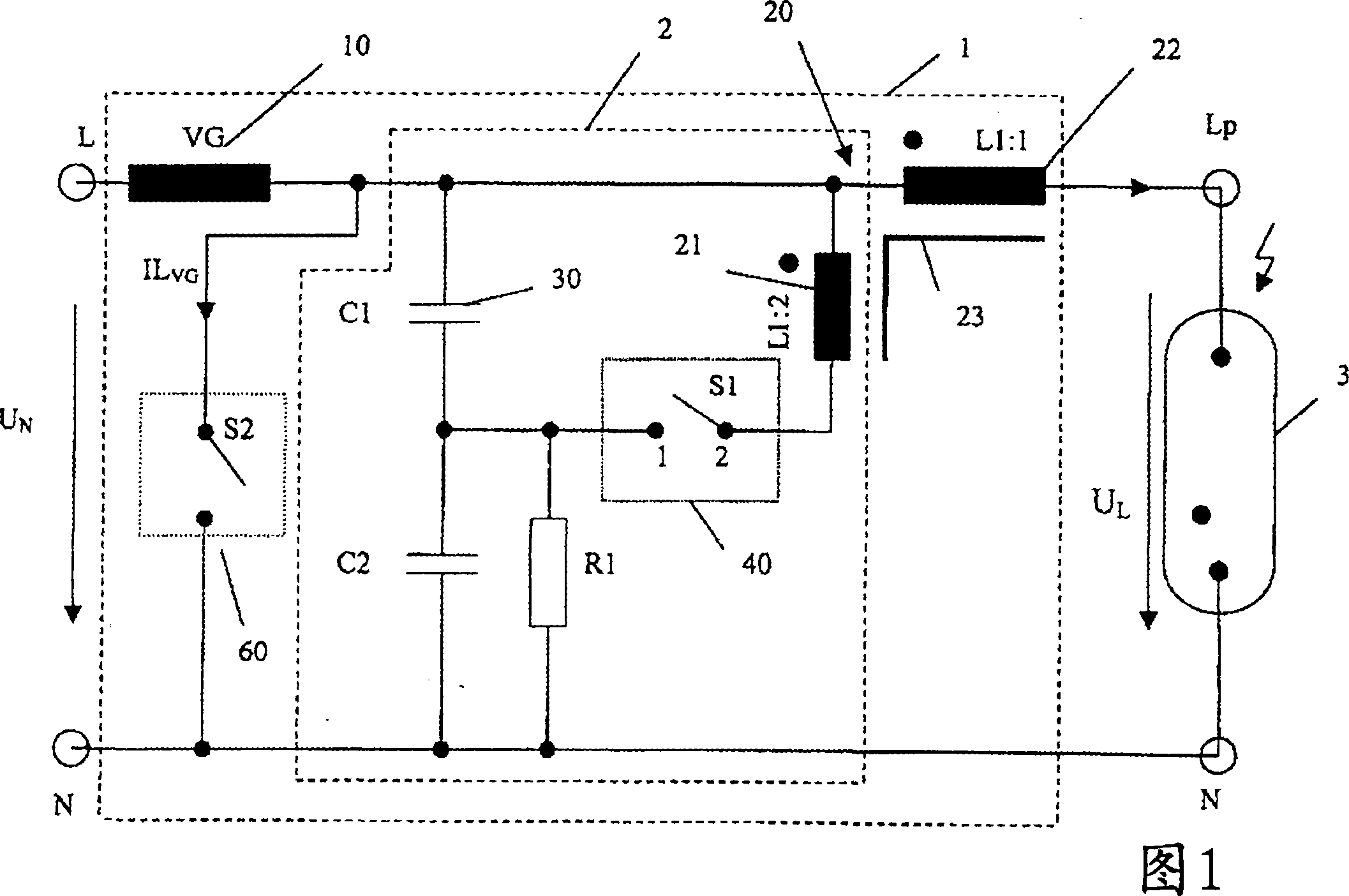

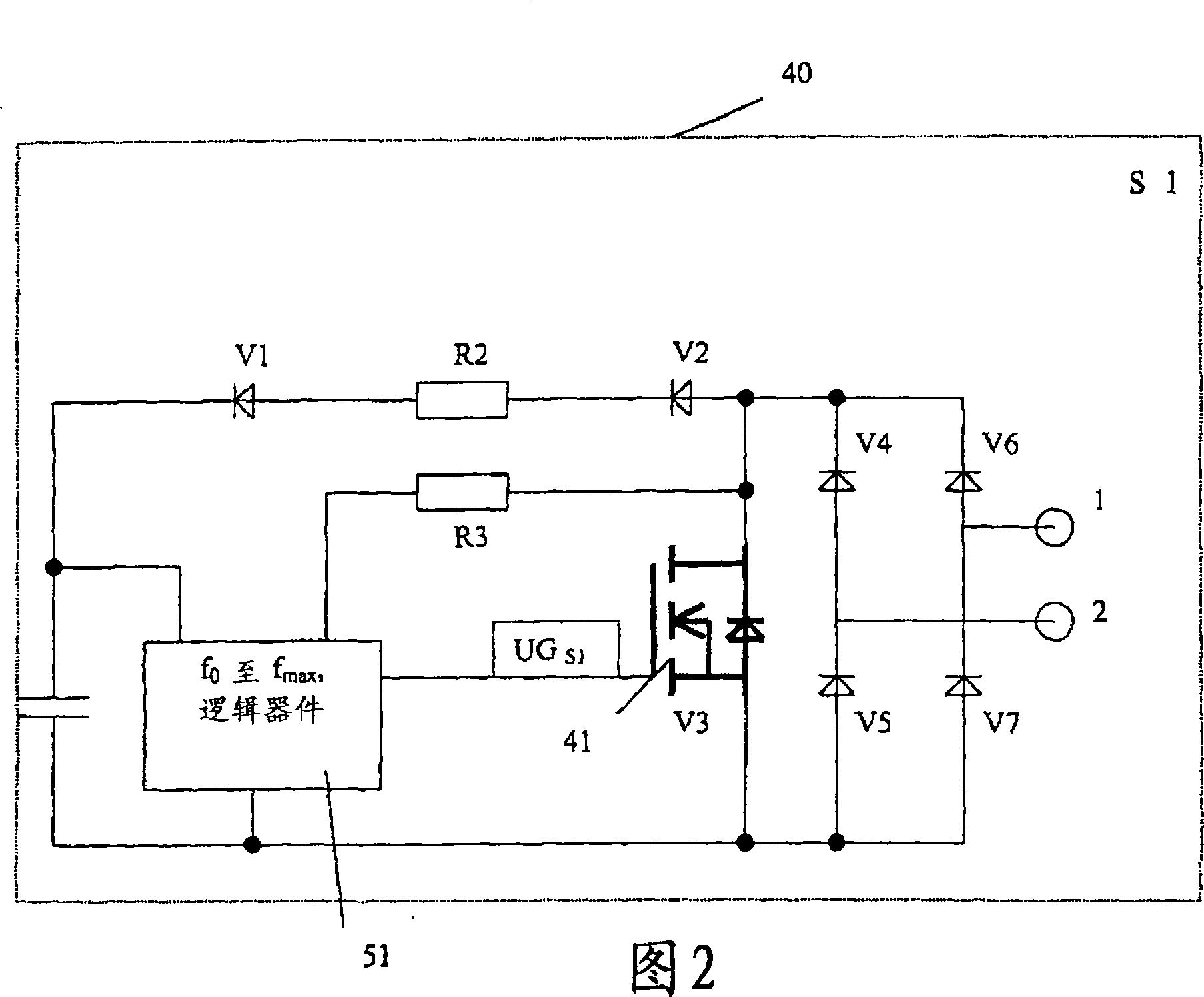

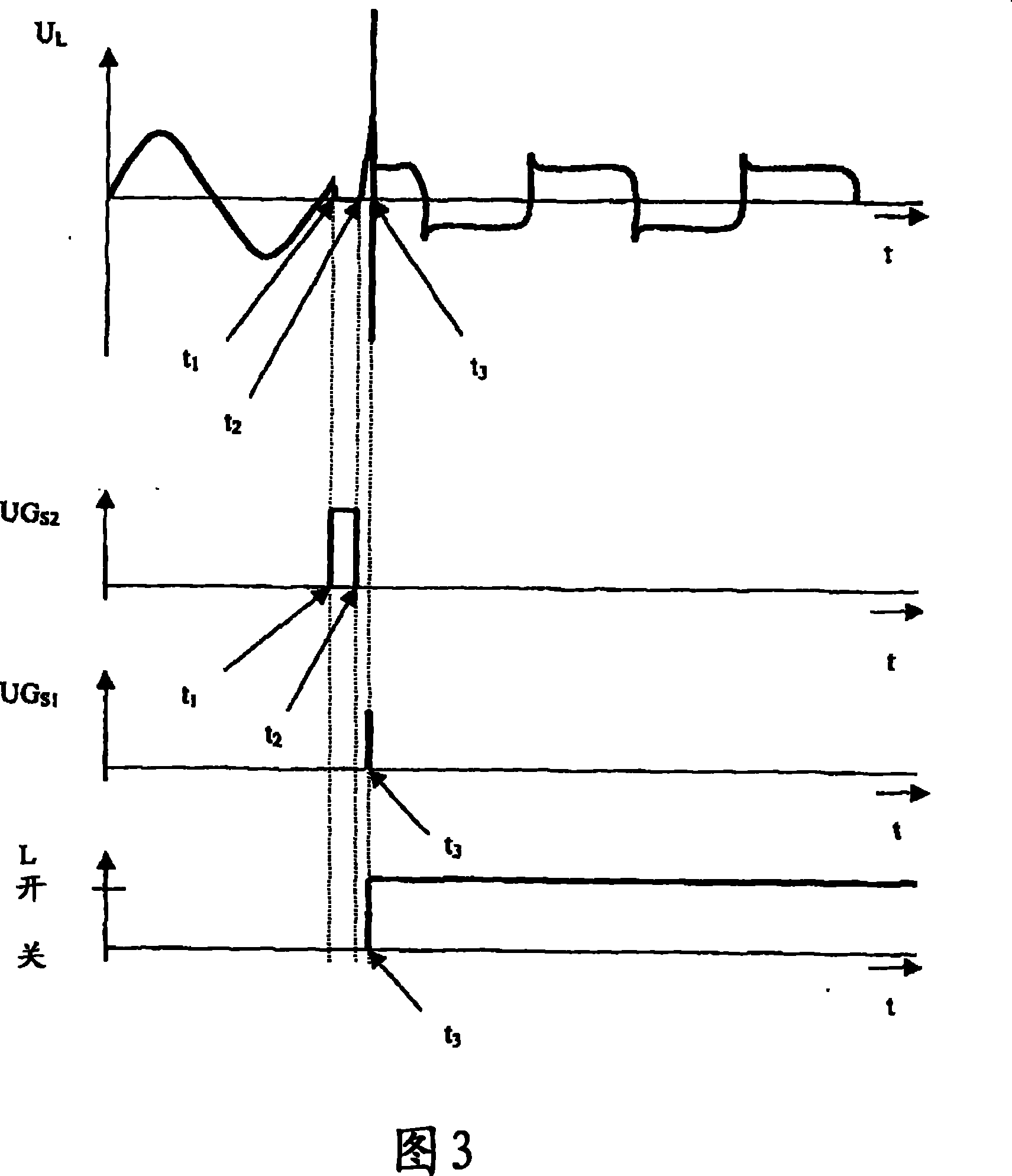

[0033] figure 1 An ignition circuit arrangement 1 according to the invention is shown together with a high-pressure gas discharge lamp 3 to be ignited. Supply voltage U N is applied to the input terminals L, N. The lamp 3 is powered by the lamp choke 10 of a conventional CBD and the secondary side coil winding 22 of the ignition transformer 20 . The ignition trigger circuit 2 includes, as main elements, a surge capacitor 30 chargeable by a parallel circuit composed of a capacitor C2 and a resistor R1, and a primary side coil winding 21 of an ignition transformer 20 . The primary side coil winding 21 is coupled to the secondary side coil winding 22 connected in series with the lamp 3 through an ignition transformer core 23 for transmission and voltage transformation of ignition pulses. A first switching device with an associated controller for triggering the ignition pulse is provided in the trigger circuit 2 , as indicated by reference numeral 40 . Furthermore, the ignitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com