Apparatus and method for die bonding

A technology of solid crystal and mobile devices, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the time-consuming, difficult to use high-precision crystal-bonding process, and is not suitable for high-precision crystal-bonding Process and other issues, to avoid time-consuming, reduce the steps of die-bonding heating, and achieve the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following examples illustrate the crystal bonding device and the crystal bonding method of the present invention. It should be noted here that the drawings are drawn in a slightly simplified or slightly exaggerated manner, which is to facilitate the understanding of the present invention. this invention.

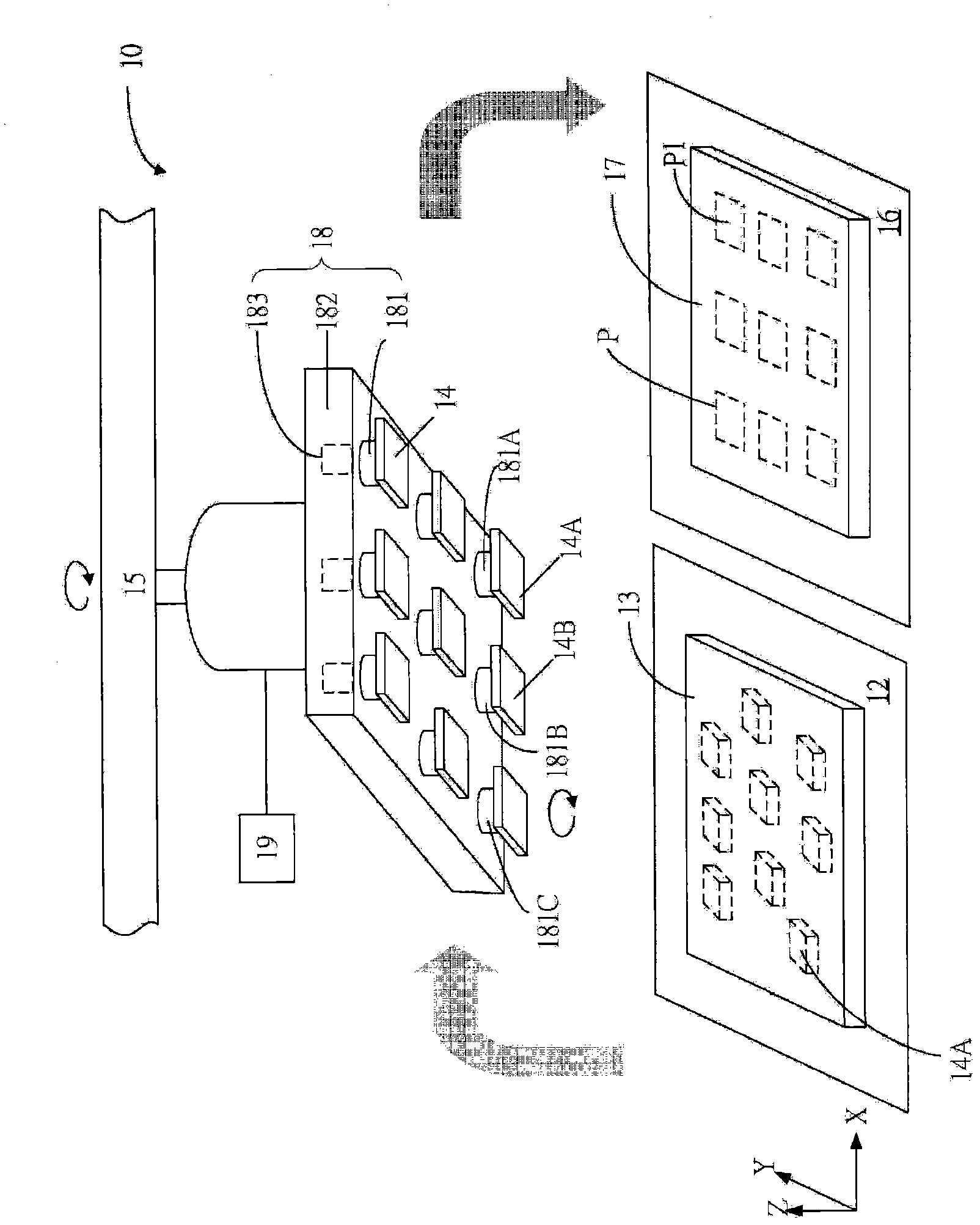

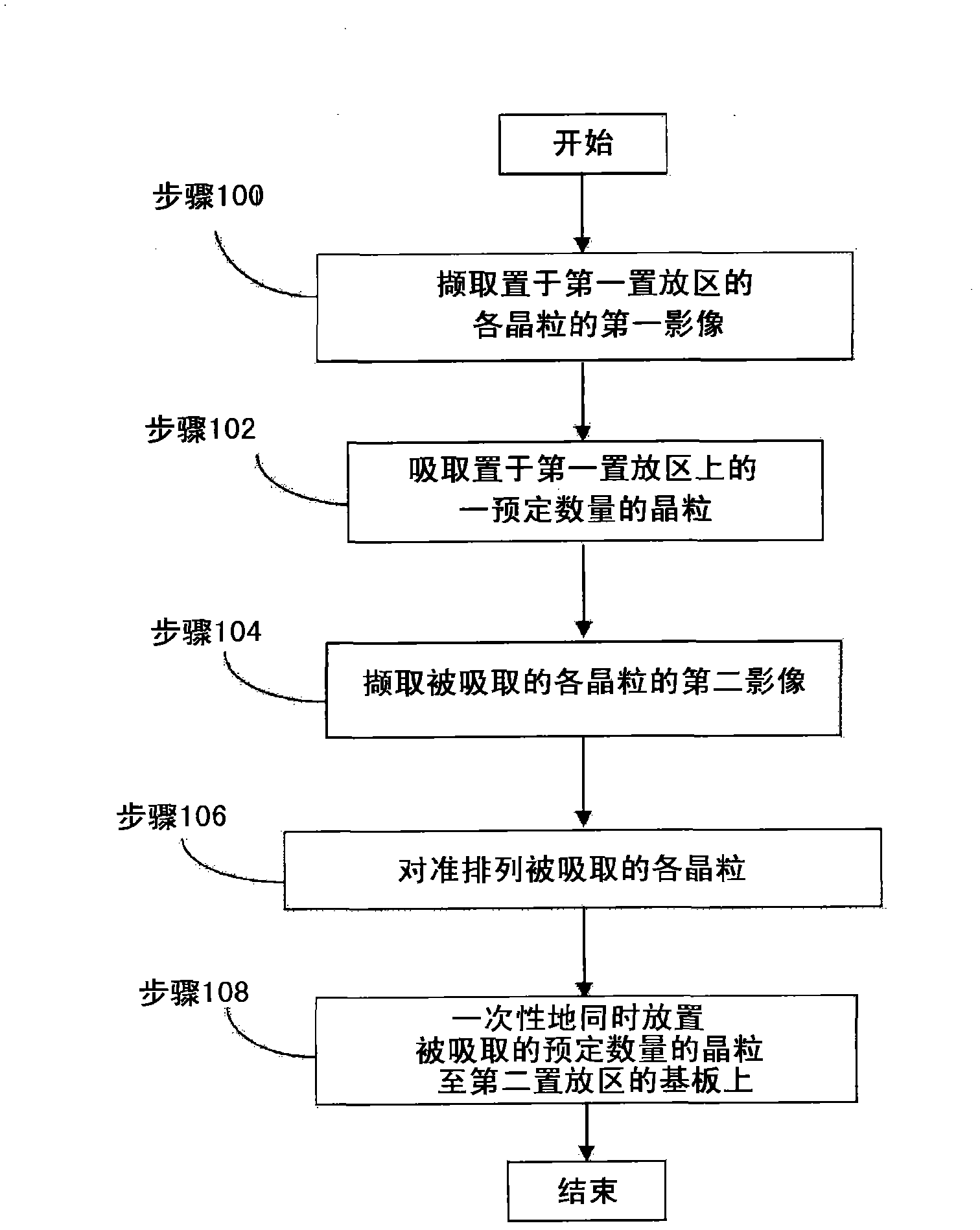

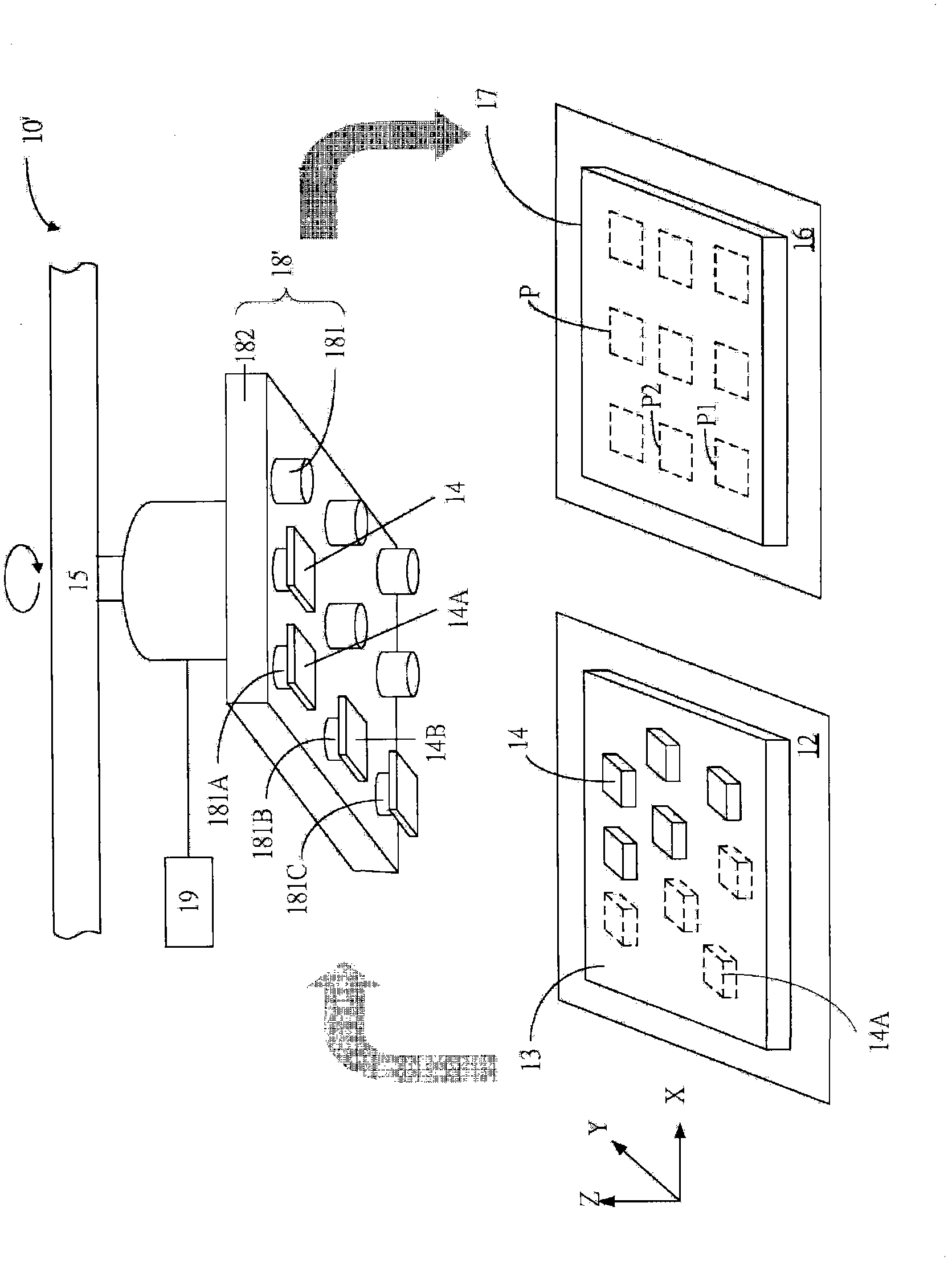

[0055] First, see Figure 1A , which is a schematic diagram of the crystal bonding device 10 according to the first preferred embodiment of the present invention. The die-bonding device 10 of this embodiment is characterized in that it can simultaneously, sequentially, or partly simultaneously / partially pick up multiple dies at one time, and fine-tune the relative positions between the dies to accurately position each die, and then These dies are fixed on the substrate at one time.

[0056] In detail, the die bonding device 10 includes a die aspirator 18 , and the die aspirator 18 has a plurality of suction nozzles 181 . The grain sucker 18 is movably positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com