Formation method and etching method for amorphous carbon hard mask layer

A hard mask layer, amorphous carbon technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve high thermal budget, affect device stability, and uneven thickness uniformity of amorphous carbon hard mask layer Good and other issues, to achieve the effect of maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

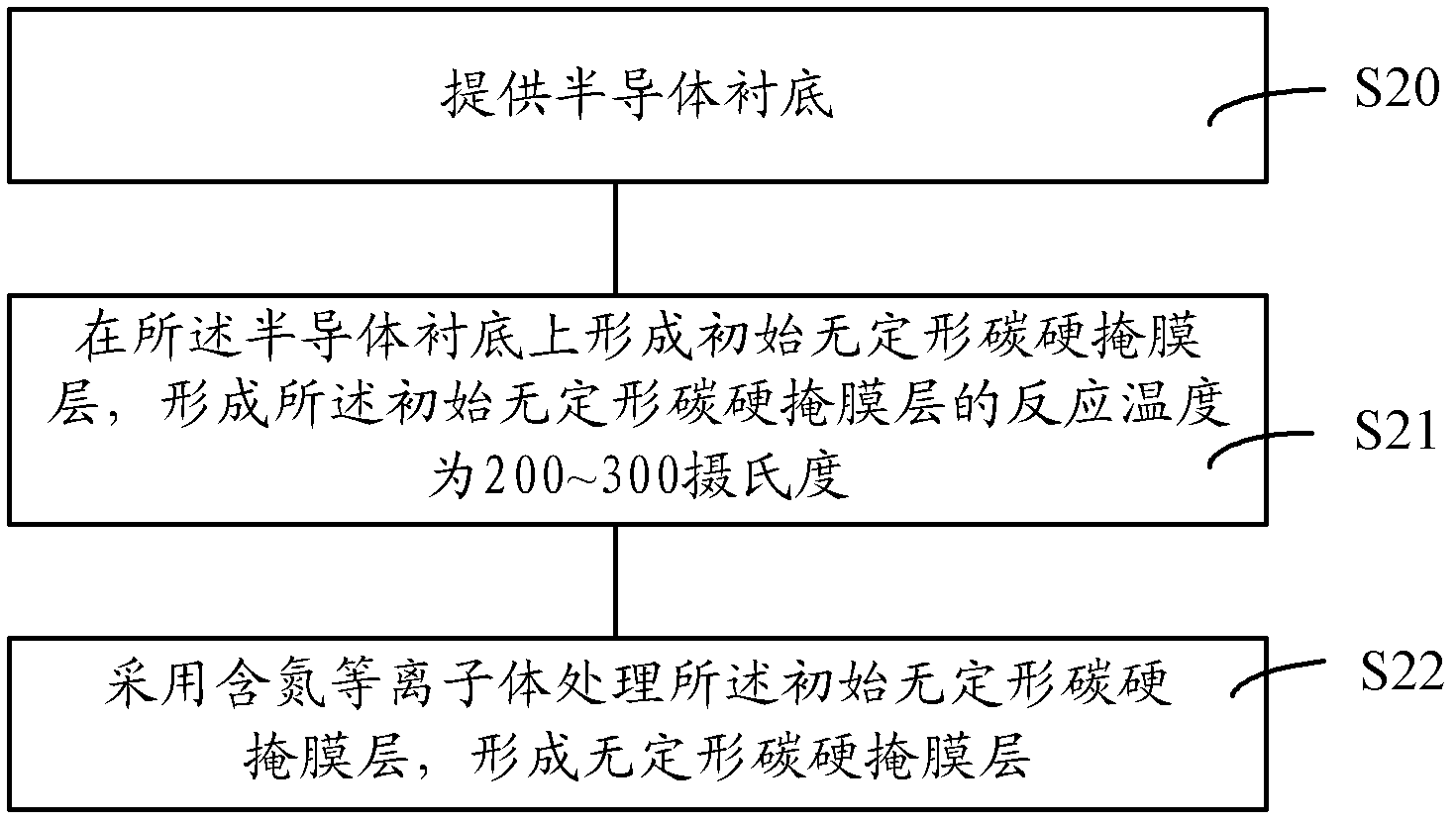

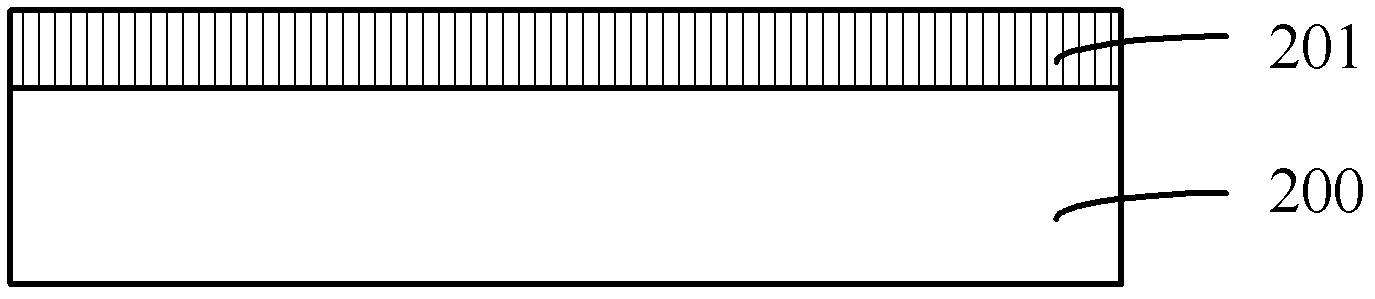

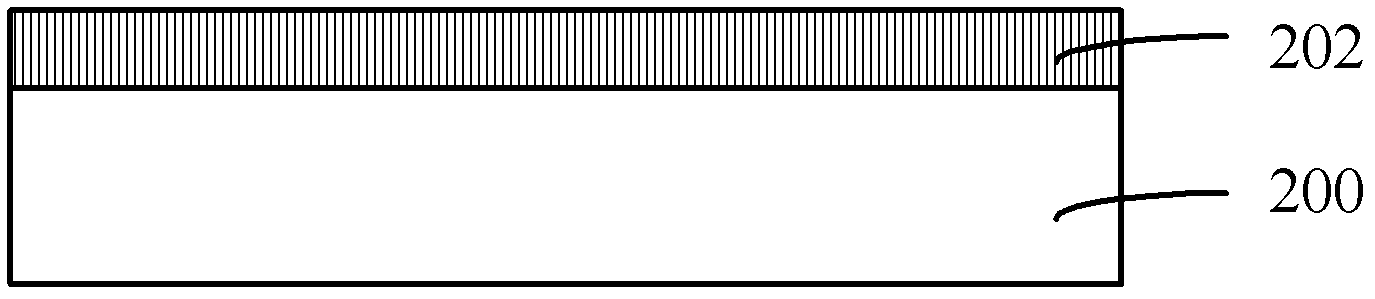

[0038] The inventor found in the process of making the amorphous carbon hard mask layer that when the amorphous carbon hard mask layer is formed by the existing plasma enhanced chemical vapor deposition process (PECVD), due to the high temperature of 400-600 degrees Celsius, Higher temperature affects the distribution and activity of dopant ions in the substrate or (polysilicon) POLY. The higher the temperature, the more serious the effect, which increases the thermal budget for making the amorphous carbon hard mask layer, and the formation of high temperature without The uniformity of the thickness of the shaped carbon hard mask layer is not good. When the photoresist layer is subsequently formed on the amorphous carbon hard mask layer, the uniformity of the thickness of the photoresist layer is affected, and abnormal photolithographic patterns are formed after exposure and development. , reducing the stability of the device.

[0039] In order to reduce the thermal budget, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com