Cylinder type magnesium alloy automatic purification quantitative device

A quantitative device and magnesium alloy technology, applied in the field of automatic purification of magnesium alloy ingots and magnesium alloy die-casting, quantitative feeding devices, can solve the problems of increasing production costs, increasing investment, etc., to reduce the entry of impurities, improve quality, less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

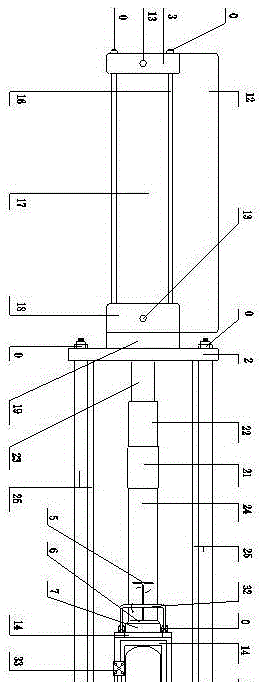

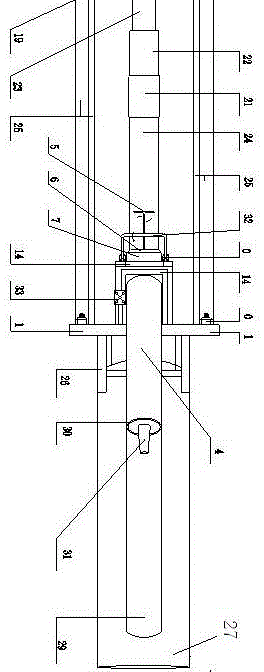

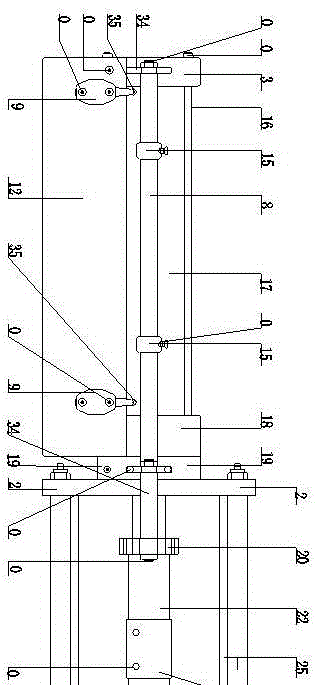

[0033] Examples: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the shape of this embodiment is an upper, middle, and lower three-layer rectangular parallelepiped structure, with an external water outlet connecting pipe and a discharge port;

[0034] The upper layer is a hydraulic oil cylinder, a travel switch 9 and a travel slide rod. The travel switch 9 is installed on the travel switch mounting plate 12, and the travel switch mounting plate 12 is installed on the upper cylinder cover 3 and the lower base 18 of the cylinder.

[0035] The hydraulic cylinder tube 17 is installed on the cylinder upper cover 3, and the cylinder piston 23 is covered with a movable sleeve 22. The movable sleeve 22 is connected to one end of the center core rod 24 through a coupling 21, and the other end of the center core rod 24 is connected to The plunger 37 is connected, the plunger 37 is arranged in the inner cavity of the magnesium alloy liquid storage cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com