Correcting device of injector arranging machine

The technology of a syringe and a feeder is applied in the field of a straightening device and a straightening device for a syringe swing feeder, which can solve problems such as inconvenience, and achieve the effects of stable reclaiming process, simple structure and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

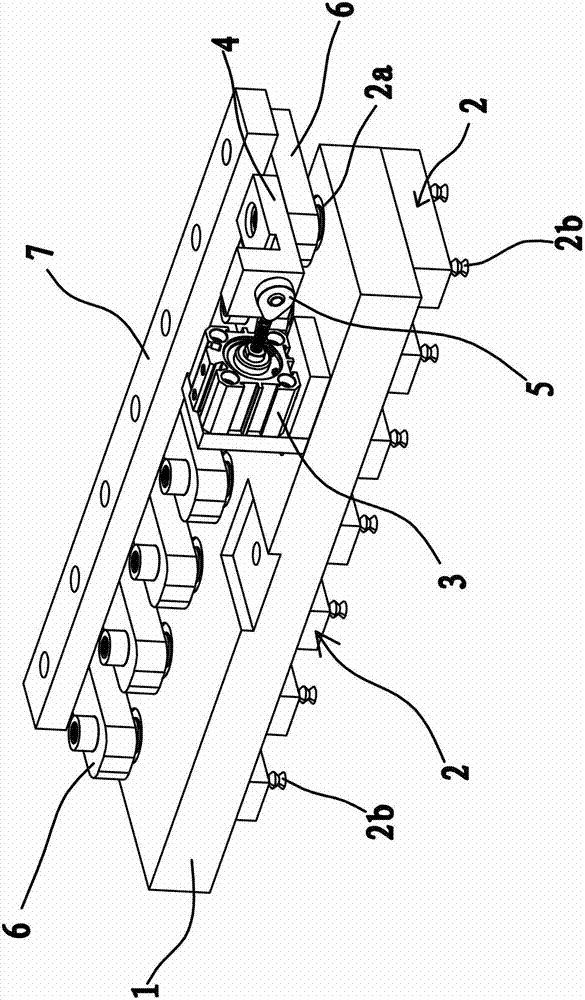

[0024] The correcting device of the syringe pendulum machine is set on the base on one side of the workpiece conveying mechanism of the pendulum machine, the correcting device is set on the base, and the base is also equipped with a lifting device that can drive the correcting device to move up and down And a translation device for horizontal reciprocating movement.

[0025] Such as figure 1 As shown, the correcting device of the syringe pendulum machine includes a support 1, and a plurality of retrieving mechanisms 2 that can position the syringe and the support 1 are axially fixed on the support 1, and the number of retrieving mechanisms 2 and the rollers The number of syringes to be corrected each time is the same. A plurality of sets of retrieving mechanisms 2 are arranged on the support 1, and a plurality of workpieces can be positioned simultaneously at one time, thereby improving production efficiency.

[0026] One end of the retrieving mechanism 2 is a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com