Aseptic cold filling valve

An aseptic cold filling and filling nozzle technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of poor material flow, large measurement deviation of cold filling valve, inconsistent product liquid level, etc. Improve cleaning efficiency, eliminate hygienic dead corners, and smooth channel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

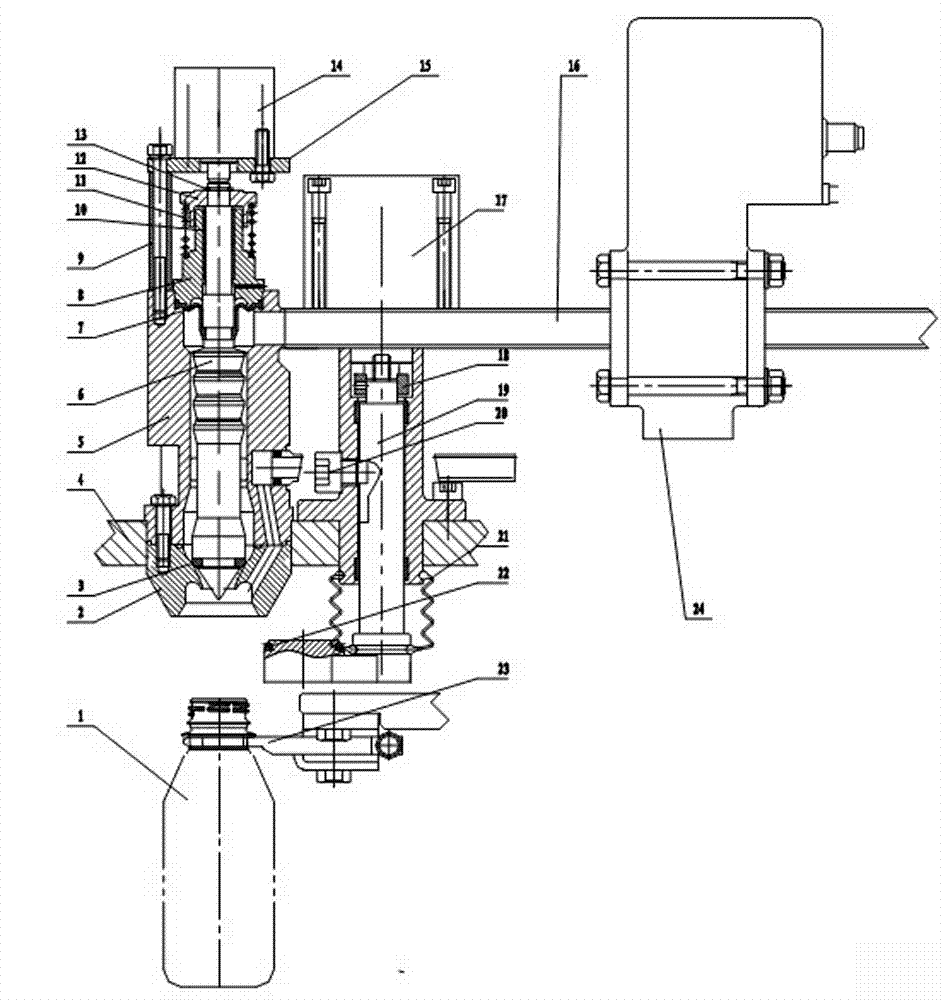

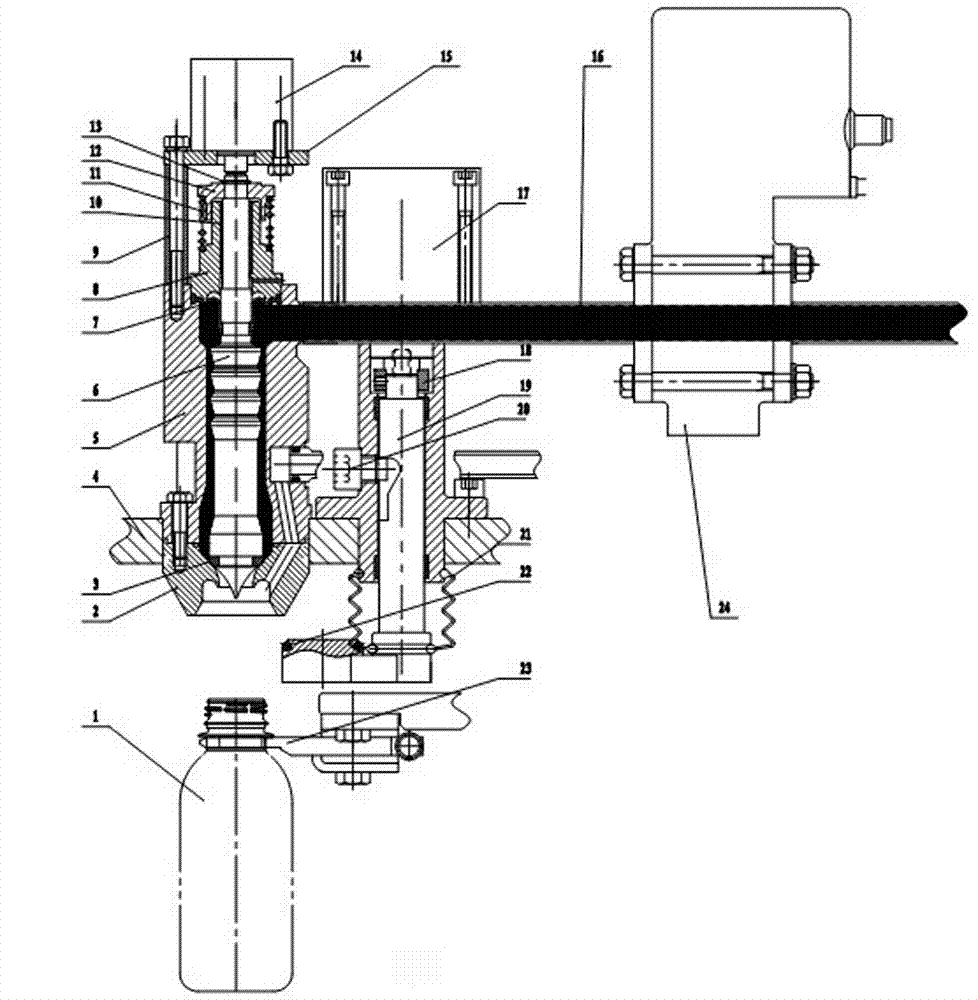

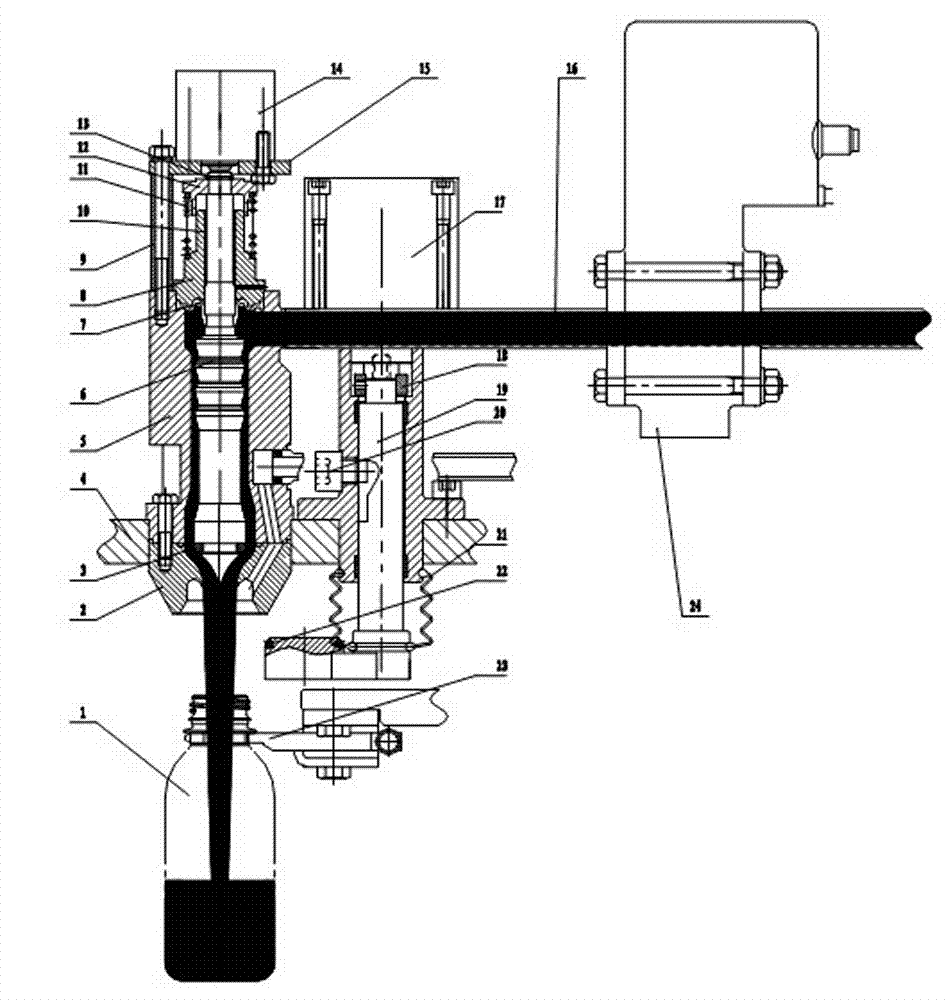

[0017] Such as figure 1 As shown, the aseptic cold filling valve of the present invention mainly includes a flow meter 24, a filling cylinder 14, a spring compression ring 12, a valve opening spring 11, a linear bearing 10, a guide compression sleeve 8, a valve diaphragm 7, and a valve core 6. Valve body 5, sealing ring 3 and filling nozzle 2; among them:

[0018] The valve body 5 is fixed on the filling valve mounting plate 4, the guide pressure sleeve 8 is fixed above the valve body 5, and the valve core 6 is installed in the guide pressure sleeve 8 and the valve body 5. The valve core 6 is supported on the guide by the linear bearing 10 In the compression sleeve 8, a flow channel is formed between the valve core 6 and the valve body 5; the upper edge of the valve diaphragm 7 is fixed between the guide compression sleeve 8 and the valve body 5, and the lower edge is fixed on the valve core 6 to seal the flow channel . A spring compression ring 12 is installed on the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com