Steel tube lattice column connection device

A connecting device and lattice column technology, which is applied in the direction of building structure, housing structure support, housing structure support, etc., can solve the problems of insufficient strength of the steel pipe fastener type support frame and the expensive price of the steel lattice column, and achieve rigidity and The effect of good strength, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

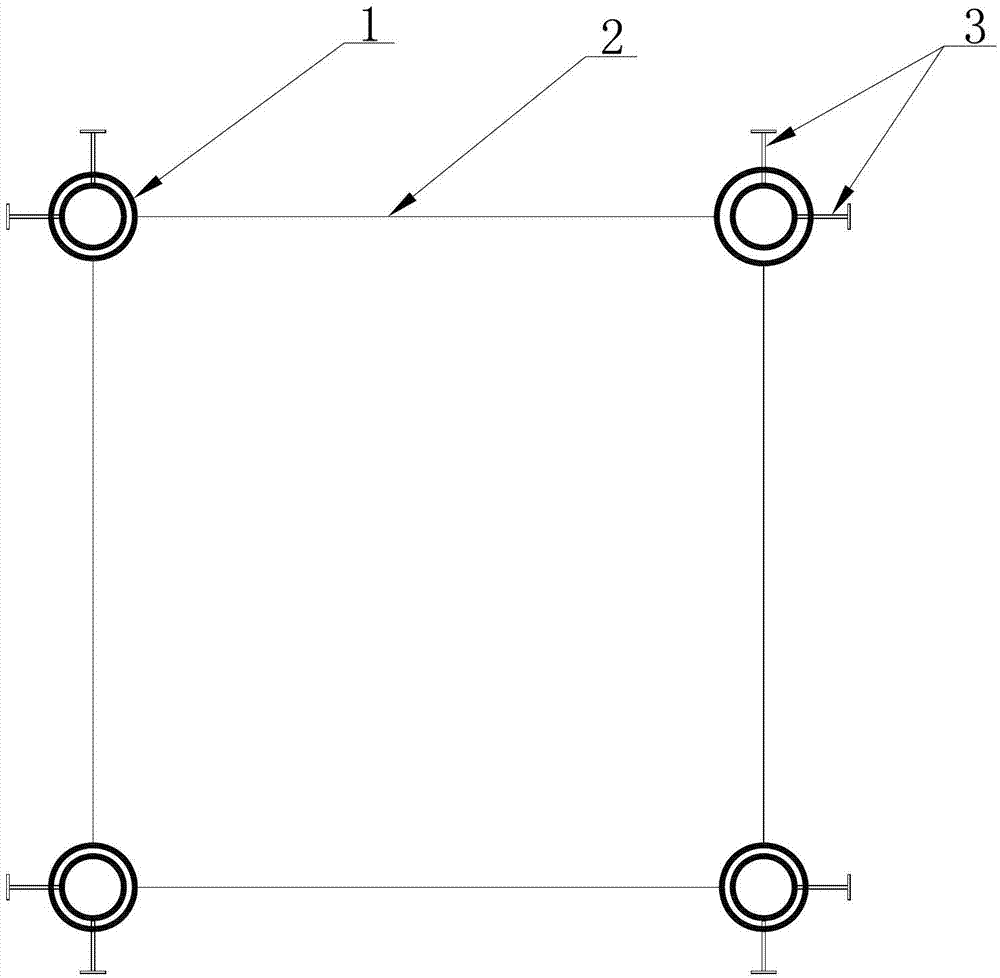

[0012] see figure 1 , a steel pipe lattice column connection device disclosed in the present invention, comprising several sleeves 1 and several connecting steel bars 2 for connecting the sleeves 1, the two ends of two adjacent connecting steel bars 2 are respectively welded and fixed to the corresponding sleeves 1 , and each casing 1 is provided with at least one locking piece 3 for fixing the steel pipe. The inner diameter of the casing 1 is slightly larger than the outer diameter of the connecting steel pipe.

[0013] In order to make the connection of the present invention more reliable, as preferred, four connecting steel bars 2 are provided in total in this embodiment, and the four connecting steel bars 2 together form a rectangular frame, and each corner of the rectangular frame is welded One set of tubes1.

[0014] Two locking pieces 3 are arranged on each sleeve 1 , and the two locking pieces 3 are respectively arranged corresponding to the inner ends of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com