led lamp radiator and led lamp

A technology of LED lamps and radiators, applied in the field of lighting, can solve the problems of low heat dissipation efficiency, low radiator height, and affecting visual effects, etc., achieve high heat dissipation efficiency, meet heat dissipation requirements, and improve heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

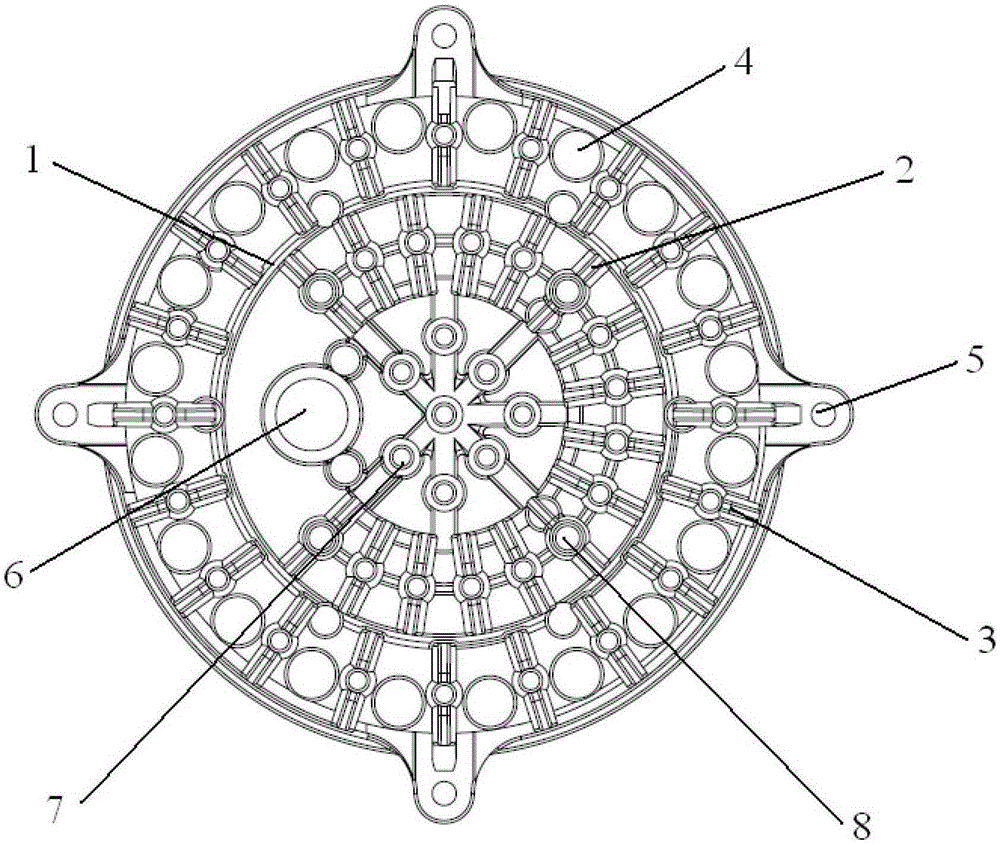

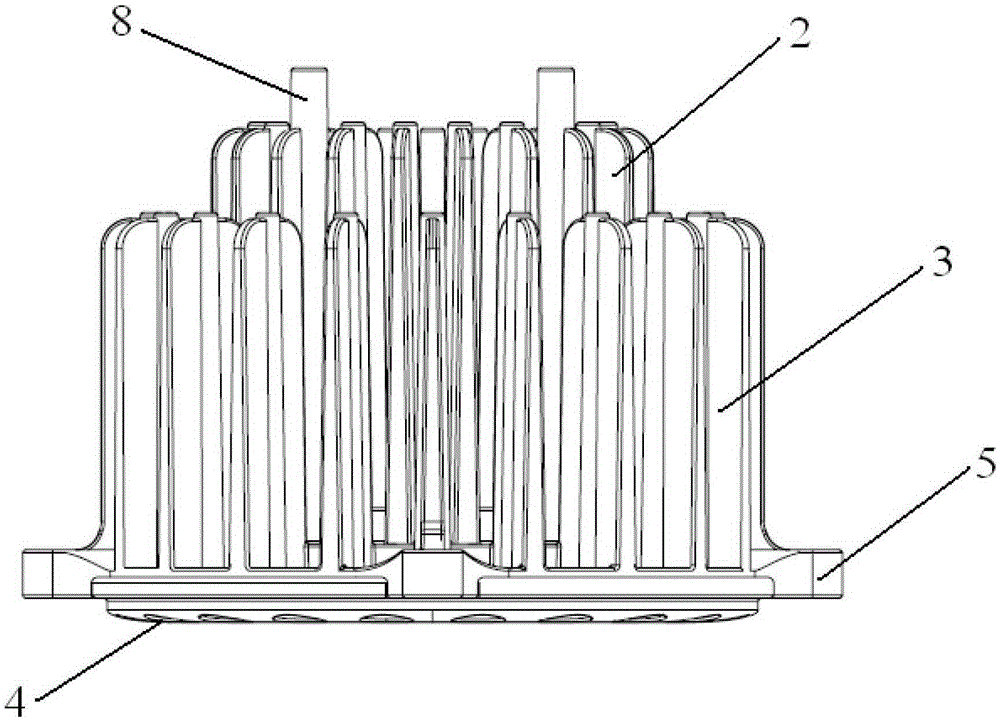

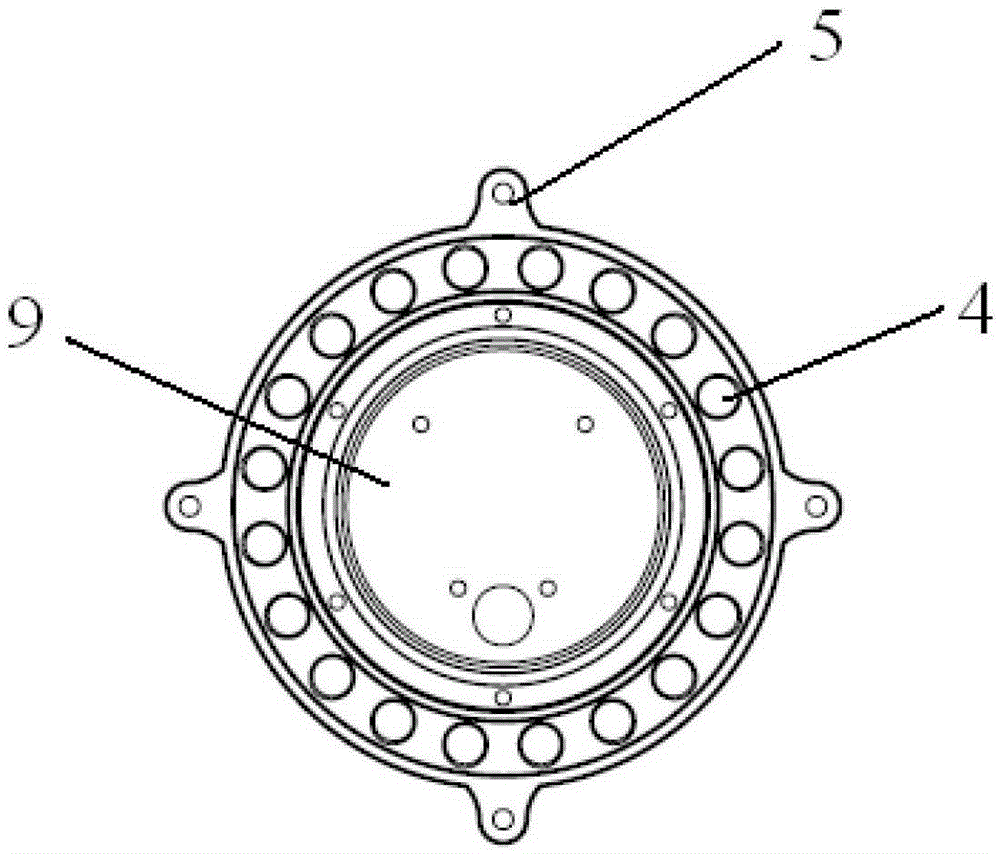

[0046] In the first embodiment of the present invention, the LED lamp heat sink includes:

[0047] Ring stiffener

[0048] An outer fin layer, which is arranged on the outer side of the annular reinforcing rib;

[0049] An inner fin layer, which is arranged on the inner side of the annular reinforcing rib;

[0050] The outer fin layer includes a plurality of outer fins distributed along the circumferential direction of the ring-shaped reinforcing rib, and the plurality of outer fins extend along the radial direction of the ring-shaped reinforcing rib;

[0051] The inner fin layer includes a plurality of inner fins distributed along the circumferential direction of the annular reinforcing rib, and the plurality of inner fins extend along the radial direction of the annular reinforcing rib;

[0052] The plurality of outer radiating fins and the plurality of inner radiating fins are arranged in a staggered arrangement, wherein the radial extension line of each inner radiating fin is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com