Wave-preventing air sac leakage detecting device and wave-preventing air sac leakage detecting system of tank truck

A leak detection, liquid tank truck technology, used in measuring devices, liquid tightness measurement using liquid/vacuum degree, fluid tightness testing, etc. In order to improve the effectiveness and reliability, the detection results are accurate, and the reliability is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present application is further described in conjunction with the following examples.

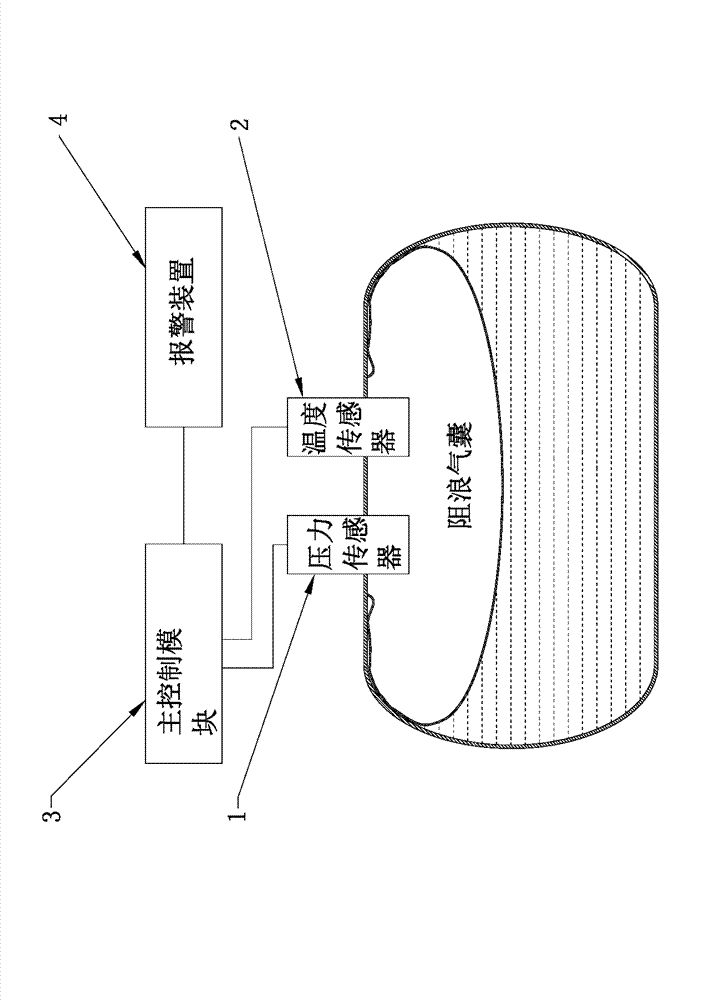

[0023] A specific embodiment of a leakage detection device for a liquid tank vehicle wave-stopping airbag of the present application, such as figure 1 As shown, it includes: a pressure sensor 1, a temperature sensor 2 and a main control module 3. The pressure sensor 1 acquires the pressure value in the wave-breaking airbag to be detected in real time and transmits the pressure value to the main control module 3. The temperature The sensor 2 acquires the temperature value of the gas in the wave-breaking airbag to be detected in real time and transmits the temperature value to the main control module 3, and the main control module 3 judges whether the wave-breaking airbag to be detected is leakage. It also includes an alarm device 4 connected to the main control module 3, and the main control module 3 activates the alarm device 4 when detecting the leakage of the wave breaking airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com