Mobile object encoding and decoding device, and railway bogie positioning device and method

A technology of encoding and decoding and rail car, applied in the field of rail car positioning device and moving object encoding and decoding, can solve the problems of high cost, complex structure, low positioning accuracy of positioning device, etc., and achieve low cost, simple device structure and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

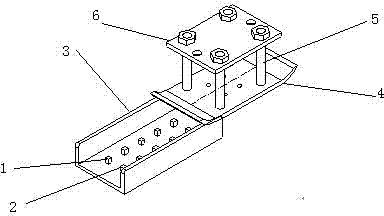

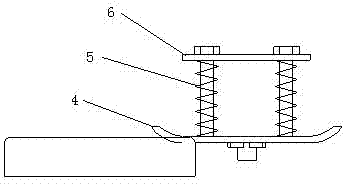

[0040] Such as figure 1 , 1 is a group of code bits, 2 is a group of code reading bits, 3 is a code disc, 4 is a boat-shaped bottom plate of a track trolley, 5 is a floating suspension pin, and 6 is a mounting bracket.

[0041]In this embodiment, the code disk is arranged on the ground between the two tracks where the rail trolley travels, and is located at the position of the work station where the rail trolley needs to stop. The coding bits are arranged side by side on the bottom plate of the coding disc, and the reading bits are set in one-to-one correspondence with the coding bits of the coding disc. On the coding bits, according to the coding method, an encoding induction block is set on the required coding bits. Each reading bit Both are provided with code-reading induction blocks. In this embodiment, both the code-reading induction block and the encoding induction block are metal blocks, wherein the encoding metal blocks are used to encode each operation site of the rai...

Embodiment 2

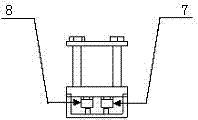

[0054] In this embodiment, the coding disk is arranged at the position before the parking operation site of the rail trolley, and a positioning disk is also provided on the basis of Embodiment 1, and the positioning disk is also arranged on the ground between the two tracks where the rail trolley travels. , the positioning plate is installed on the accurate parking position of the track trolley, and is used to position the track trolley, such as Figure 6 , 9 is a positioning metal block, which is located on the base plate of the positioning plate, corresponding to the accurate parking position of the track car.

[0055] When the rail trolley travels to the coding disc, after determining the code of the coding disc, if it is the station where it is going to stop, the rail trolley will slow down. When it reaches the positioning disc and detects the pulse signal sent by the positioning metal block , Immediately control the parking operation of the track trolley.

[0056] In oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com