Fixture for three-coordinate measuring machine of blade and method for establishing measuring coordinate system

A technology of three-coordinate measuring machine and measuring coordinate system, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of difficulty in measuring the coordinate system of blades and low measurement efficiency, and achieve reduction of time and difficulty, high positioning accuracy, and simple fixture structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

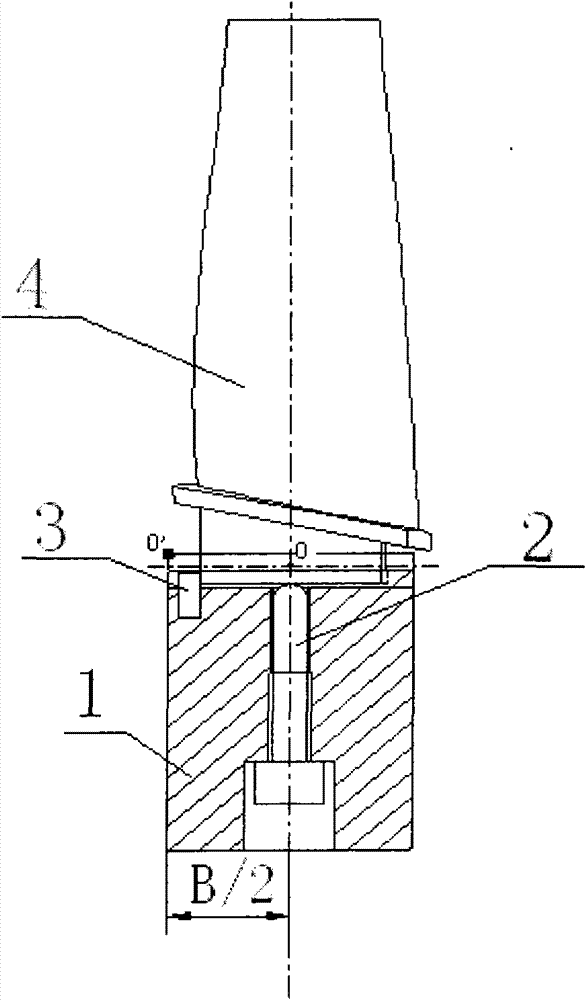

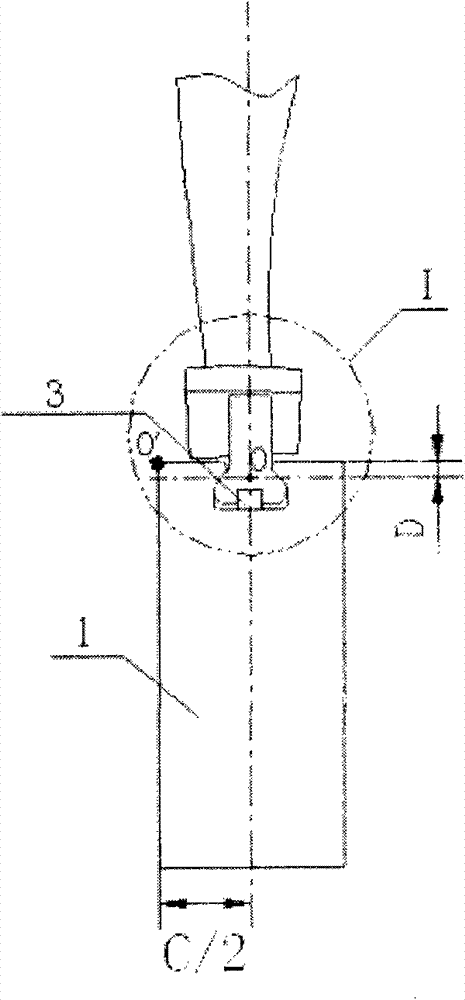

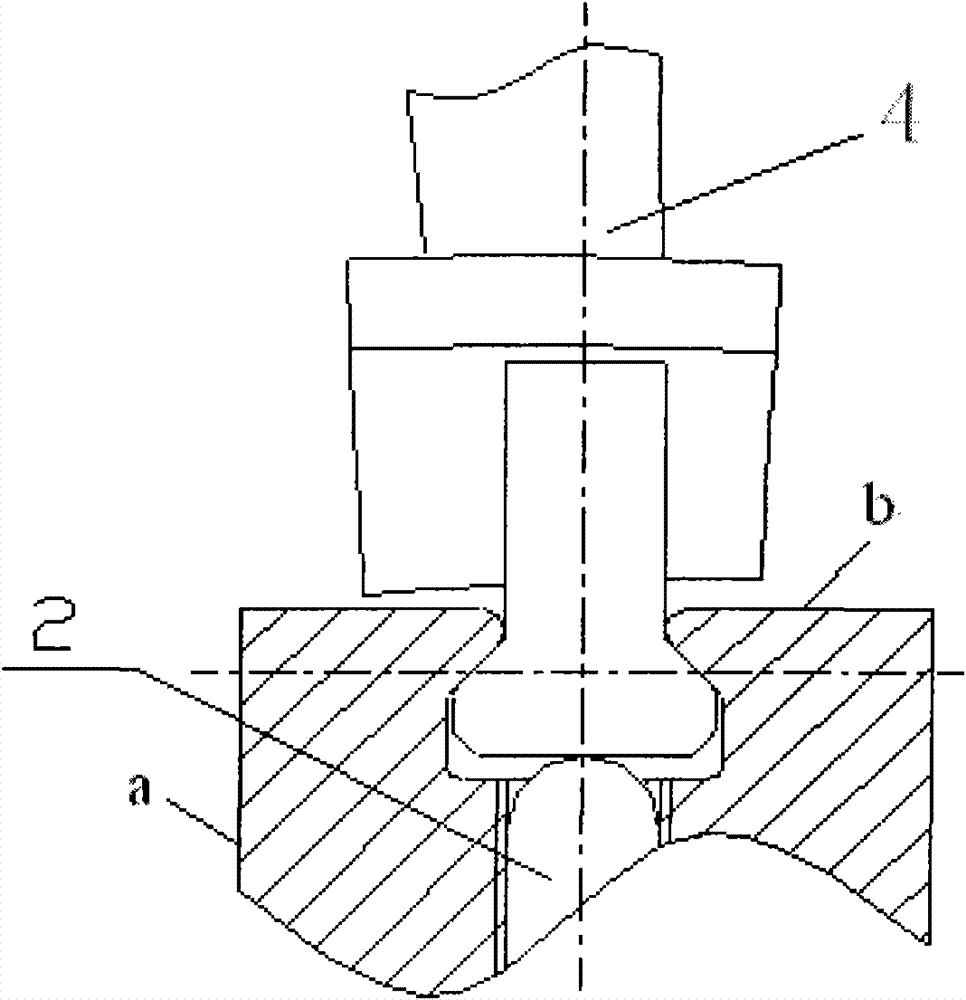

[0026] This embodiment is a fixture used for measuring blades of a certain type of aero-engine, including a fixture body 1 , jacking screws 2 and positioning pins 3 .

[0027] Such as figure 1 As shown, the clip body 1 of this embodiment is a cuboid, and its length is the same as that of the root of the blade. There is a V-shaped tongue and groove on the upper surface of the clamp body 1 . The groove walls on both sides of the V-shaped tenon groove are wedge-shaped surfaces, and the wedge-shaped surfaces completely coincide with the wedge-shaped surfaces of the blade root. The V-shaped tongue and groove are distributed along the length direction of the clip body and are located on the centerline of the width of the clip body 1 . There is a blind installation hole for the positioning pin shaft 3 at the groove bottom at any one end of the V-shaped tenon groove, and the center line of the blind installation hole is located in the longitudinal symmetrical plane of the V-shaped g...

Embodiment 2

[0041] This embodiment is a fixture used for measuring blades of a certain type of aero-engine, including a fixture body 1 , jacking screws 2 and positioning pins 3 .

[0042] Such as figure 1As shown, the clip body 1 of this embodiment is a cuboid, and its length is the same as that of the root of the blade. There is a V-shaped tongue and groove on the upper surface of the clamp body 1 . The groove walls on both sides of the V-shaped tenon groove are wedge-shaped surfaces, and the wedge-shaped surfaces completely coincide with the wedge-shaped surfaces of the blade root. The V-shaped tongue and groove are distributed along the length direction of the clip body and are located on the centerline of the width of the clip body 1 . There is a blind installation hole for the positioning pin shaft 3 at the groove bottom at any one end of the V-shaped tenon groove, and the center line of the blind installation hole is located in the longitudinal symmetrical plane of the V-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com