Optical detection clamp for thin-wall spiral groove type part

An optical detection and spiral groove technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of non-blocking parts, and achieve the effects of avoiding reflection, stable positioning, and fast matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

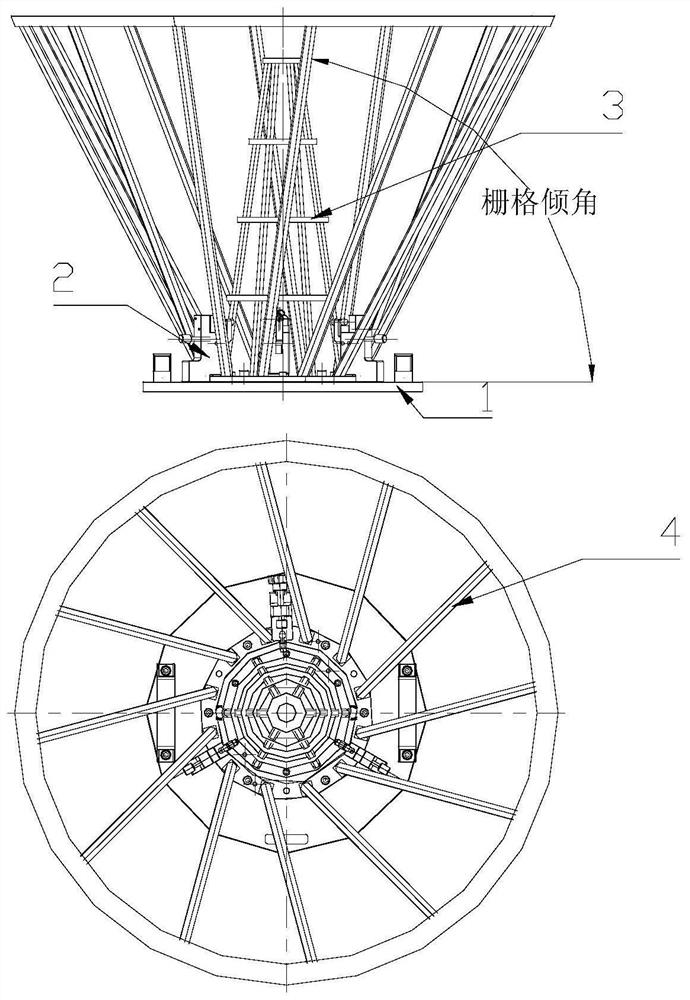

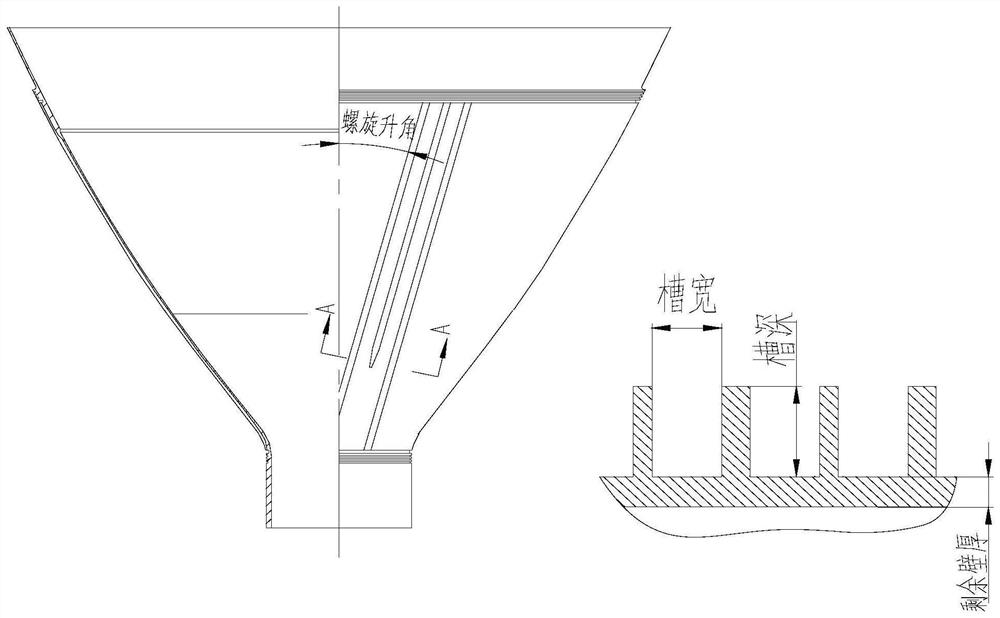

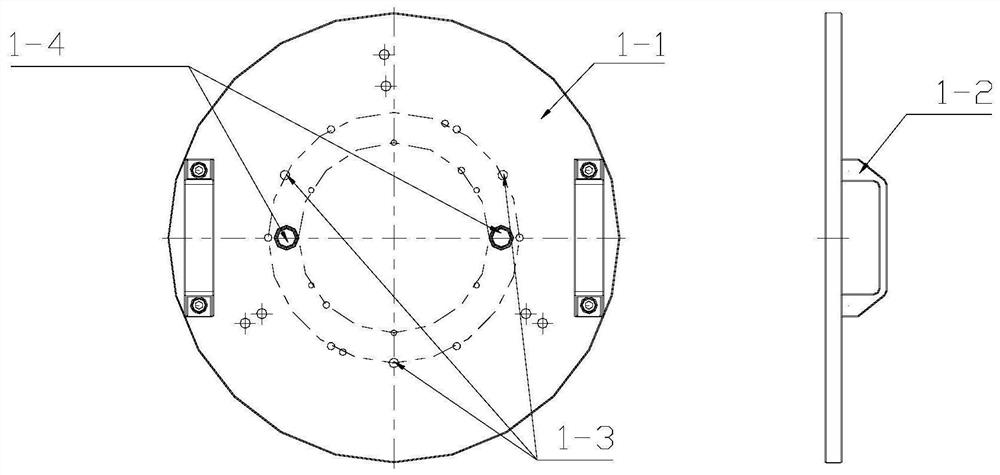

[0028] Refer to the attached Figure 1-6 , the present invention will be described in detail.

[0029] The invention provides an optical inspection fixture for thin-walled spiral groove parts, which includes a connection base 1, a clamping and positioning platform 2, an inner grid 3, an outer grid 4, and marking points. The connecting base 1 is composed of a metal disc 1-1, a handle 1-2, a connecting hole 1-3, and a positioning pin hole 1-4. The handle is connected with the metal disc 1-1 through bolts, and the connecting hole 1-3 is connected with the positioning pin The holes 1-4 are used to position and connect the fixture on the working turntable of the three-dimensional optical scanner; the clamping and positioning platform 2 is composed of three supporting blocks 2-1, and the supporting blocks 2-1 are connected to the metal disc 1-1 by bolts. Connection, the upper end of each support block 2-1 is provided with a groove, and the brass spacer 2-3 is placed in the groove; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com