Touch screen

A touch screen and electrode surface technology, applied in lamination devices, instruments, electrical and digital data processing, etc., can solve the problems of poor sealing effect of touch screens, unfavorable use and storage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

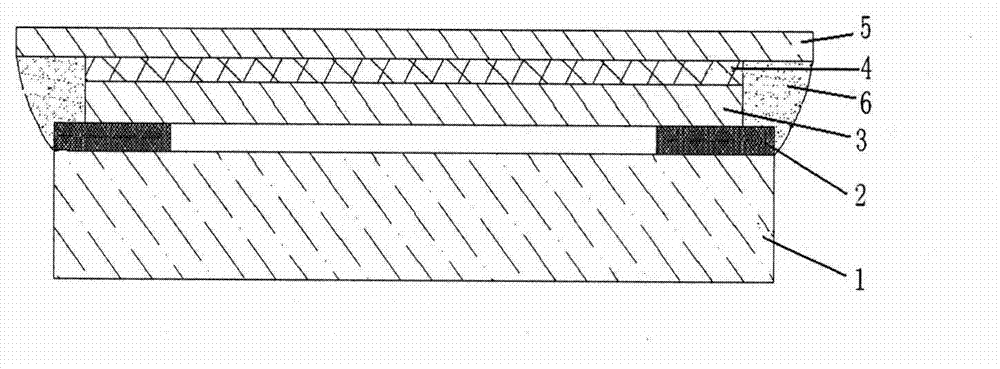

[0009] control figure 1 , a touch screen consisting of a lower electrode surface 1, a double-sided adhesive layer 2, an upper electrode surface 3, an OCA adhesive layer 4, a panel 5, and a silica gel layer 6; wherein the upper electrode surface 3 is attached to the lower electrode through the double-sided adhesive layer 2 On the upper part of the surface 1, the panel 5 is attached to the upper part of the upper electrode surface 3 through the OCA adhesive layer 4; the silica gel layer 6 covers the lower electrode surface 1, the double-sided adhesive layer 2, the upper electrode surface 3, the OCA adhesive layer 4, and the panel 5. the junction between.

[0010] The manufacturing process is as follows: firstly, the printing process of the upper electrode surface 3 and the lower electrode surface 1 is carried out respectively, and the printing process of the upper electrode surface 3 is: baking of the upper electrode → anti-etching printing of the upper electrode → etching of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com