A 3D modeling method for hole edge cracks based on finite element software

A finite element and crack technology, applied in the field of damage tolerance analysis, can solve the problems of poor automation, high difficulty of three-dimensional crack model at the edge of the hole, and long time, and achieve the effect of high automation, strong versatility, and clear method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

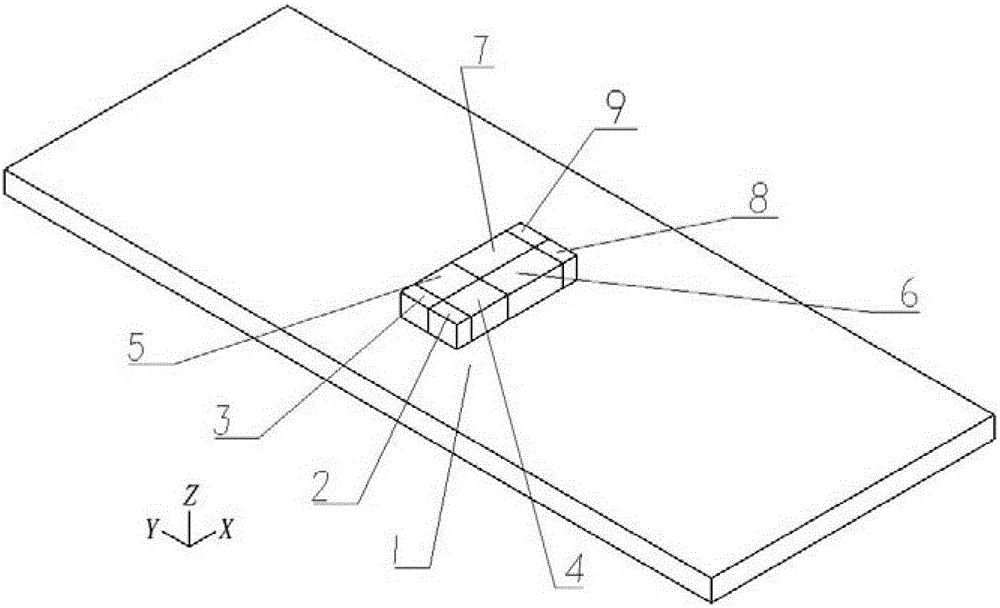

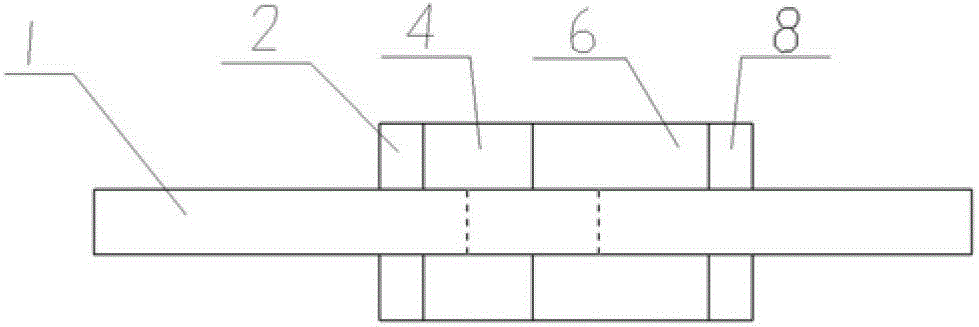

[0038] Example 1: Modeling of three-dimensional penetrating cracks on both sides of through-holes

[0039] Taking a rectangular plate with a circular through hole as an example, three-dimensional penetrating cracks are established on both sides of the hole. The size of the rectangular plate is 100×40×3mm, the through hole is located in the center of the rectangle, and the radius is 3mm; the lengths of the penetrating cracks on the sides of the holes are 2mm and 5mm respectively.

[0040] Step 1 Create a structural solid model

[0041] (1) Create a rectangular plate with a length of 100mm, a width of 40mm, and a height of 3mm;

[0042] (2) At the center of the plate, build a cylinder penetrating the plate with a radius of 3mm and a height of 10mm along the direction perpendicular to the plate;

[0043] (3) By applying Boolean operations and subtracting the cylinder from a rectangular plate, a solid model of a rectangular plate with a circular through hole can be established, ...

Embodiment 2

[0063] Example 2: Modeling of three-dimensional penetrating cracks on one side of a spot-faced hole

[0064] Countersink holes are often used as countersunk rivet holes, which are very common in aircraft structures and are a typical variable-section hole. Taking a rectangular plate with a spot-faced hole as an example, a three-dimensional penetrating crack is established on one side of the hole. The size of the rectangular plate is 100×40×3mm, the spot facing hole is located in the center of the rectangle, the hole radius is 2mm, the spot spot radius is 3mm, and the spot spot depth is 1mm; the length of the penetrating crack on one side of the hole is 5mm.

[0065] Step 1 Create a structural solid model

[0066] (1) Create a rectangular plate with a length of 100mm, a width of 40mm, and a height of 3mm;

[0067] (2) At the center of the plate, build a cylinder penetrating the plate with a radius of 2mm and a height of 10mm along the direction perpendicular to the plate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com