Exhaust gas treatment unit for an exhaust gas recirculation line

A technology for waste gas treatment and pipelines, which is used in waste gas recirculation, exhaust devices, engine components, etc., and can solve problems such as large costs and complex flanges/collars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

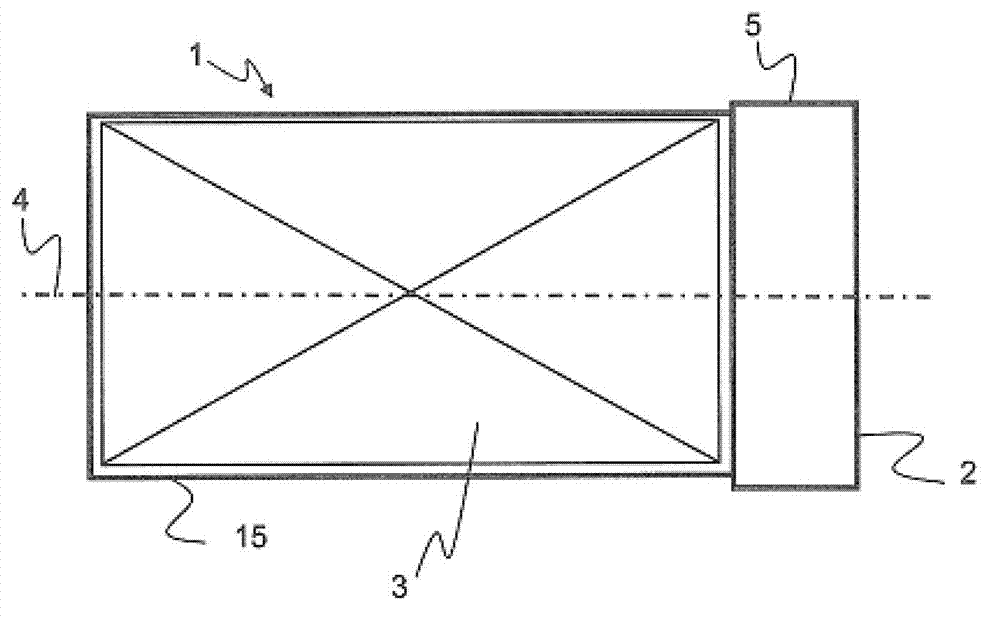

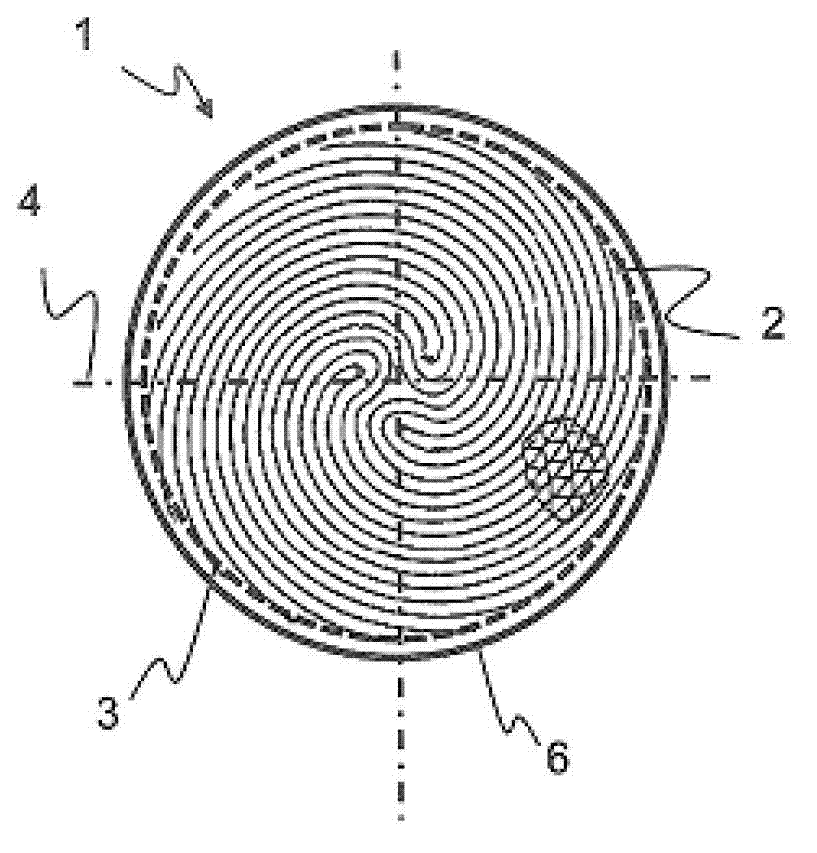

[0048] figure 1 Shown is an exhaust gas treatment unit 1 with a housing 15 and a (single) exhaust gas treatment body 3 , also with a pinch region 5 on one open side 2 and with a main axis 4 . The pressing area 5 is concentric with the main axis of the exhaust gas treatment body 3 and also has a step with respect to the exhaust gas treatment body 3 . figure 2 shows a plan view of the open side 2 of the exhaust gas treatment unit 1, or figure 1 The compression region 5 in the cross-section 6 of the exhaust gas treatment body 3 . It can be seen here that the cross section 6 corresponds to the shape of the exhaust gas treatment body 3 . Representatively shown here is a structure comprising alternating corrugated and smooth foils wound in an S-shape in a variety of honeycomb structures.

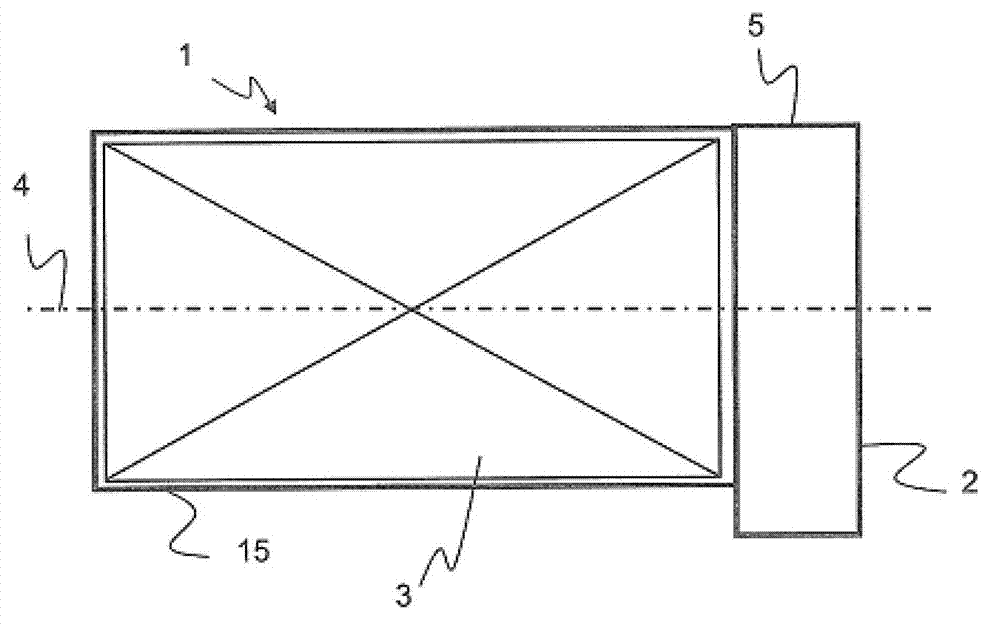

[0049] image 3 Shown is an exhaust gas treatment unit 1 with an exhaust gas treatment body 3 and an extrusion region 5 which is placed on the open side 2 of the exhaust gas treatment unit 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com